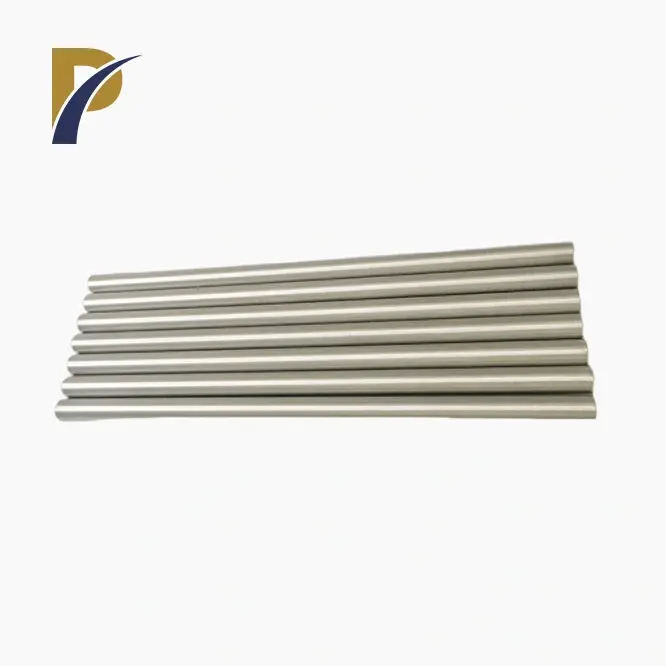

lanthanated molybdenum rod

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Aerospace components,Electronics industry,Semiconductor industry,high temperature furnace,glass melting furnace.

PRODUCT DESCRIPTION

Lanthanated Molybdenum Rod Introduction

Lanthanated molybdenum rods, offered by Shaanxi Peakrise Metal Co., Ltd., are advanced materials designed to meet the exacting demands of high-performance applications. These rods are infused with lanthanum, which significantly enhances their physical and thermal properties, making them a preferred choice for industries requiring superior heat resistance and stability.

These are distinguished by their improved strength, thermal conductivity, and oxidation resistance compared to standard molybdenum rods. This makes them ideal for use in extreme conditions such as high-temperature furnaces, aerospace components, and advanced electronic devices. Shaanxi Peakrise Metal Co., Ltd., with its extensive experience and state-of-the-art manufacturing capabilities, provides these high-quality rods to a global market, ensuring reliability and performance for all industrial needs.

Product Parameters

Standard Dimensions

| Diameter (mm) | Length (mm) | Tolerance (mm) |

|---|---|---|

| 1 - 50 | Up to 1500 | ±0.05 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 220 MPa |

| Yield Strength | 160 MPa |

| Elongation | 25% |

| Hardness (Vickers) | 250 HV |

Chemical Composition

| Element | Composition (%) |

|---|---|

| Molybdenum | ≥ 99.95 |

| Lanthanum | 0.5 - 1.5 |

| Iron | ≤ 0.05 |

| Nickel | ≤ 0.03 |

|

|

Physical and Chemical Properties

Lanthanum Doped Molybdenum Rod exhibit several superior physical and chemical properties:

Enhanced Melting Point: These rods maintain stability up to 2700°C, providing superior performance in extreme temperatures.

Superior Thermal Conductivity: Effective in transferring heat, which is crucial for high-temperature applications.

Improved Oxidation Resistance: The lanthanum addition increases resistance to oxidation, enhancing the rod’s lifespan and reliability.

High Strength and Hardness: Exhibits increased mechanical strength and hardness compared to standard molybdenum, suitable for high-stress environments.

|

|

Lanthanated Molybdenum Rod Functions

High-Temperature Stability: lanthanated molybdenum rod is ideal for applications involving extreme heat, such as in furnace components and aerospace technology.

Thermal Management: Provides efficient heat conduction in electronic devices and high-performance machinery.

Oxidation Resistance: Enhances durability in oxidative environments, extending the service life of components.

Structural Strength: Maintains structural integrity under significant mechanical stress.

Product Applications

Lanthanated molybdenum rods are versatile and serve numerous applications:

Aerospace Industry: Used in rocket nozzles, aircraft engines, and other high-temperature components.

Electronics: Essential for semiconductor production and high-temperature electrical contacts.

Metallurgy: Employed in tools and equipment that require high strength and thermal stability.

Glass Manufacturing: Used in the production of glass melting and shaping equipment.

The demand for it is growing due to their enhanced properties. Industries are increasingly adopting these advanced materials to meet the rigorous requirements of modern technology and manufacturing processes.

|

|

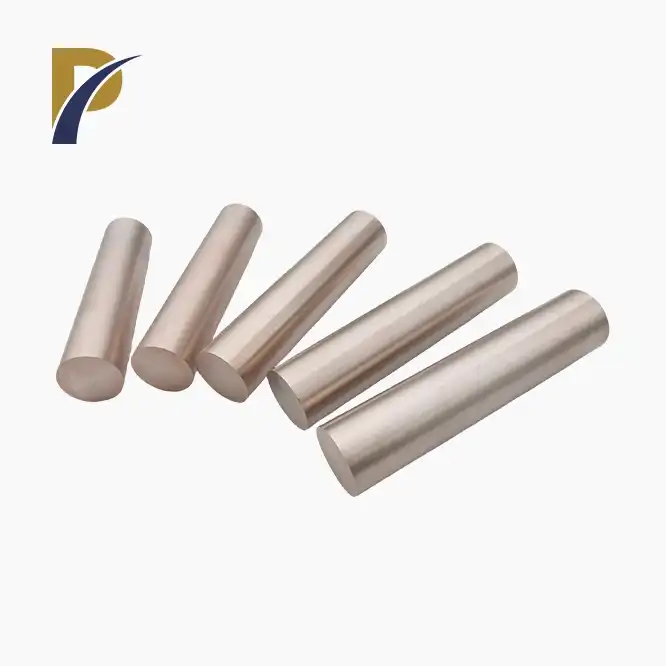

Manufacturing Process and Production Flow

Material Preparation: Lanthanum and molybdenum powders are mixed to achieve the desired composition.

Compaction and Sintering: The powder mixture is compacted and sintered at high temperatures to form solid rods.

Machining: Precision machining is performed to achieve exact dimensions and tolerances.

Annealing: The rods undergo annealing to improve their mechanical properties and relieve internal stresses.

Quality Control: Each rod is subjected to stringent quality checks to ensure it meets our high standards and specifications.

|

|

|

About Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a prominent manufacturer specializing in non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Since our focus on international markets began in 2010, we have become a leading supplier of high-quality metal products. Our facility is equipped with advanced production equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, and precision machining tools. Our commitment to quality and innovation drives us to continuously improve and meet the evolving needs of our global customers.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Packaging Options:

Wooden Crates: Ensures robust protection during shipping.

Carton Boxes: Suitable for smaller orders and lighter protection.

Foam Padding: Provides additional cushioning to prevent damage.

Waterproof and Moisture-Proof Wrapping: Protects against environmental conditions.

Custom Packaging: Tailored solutions based on customer requirements.

Logistics Methods:

Sea Freight: Cost-effective for large volume orders.

Air Freight: Quick delivery for urgent shipments.

Land Transport: Reliable for regional deliveries.

Multi-Modal Transport: Combines different transport methods for efficiency.

Courier Services: Ideal for smaller or urgent orders.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

Expertise: Over a decade of experience in non-ferrous metal production.

Advanced Technology: Utilization of cutting-edge manufacturing equipment.

Quality Assurance: Comprehensive quality control and testing procedures.

Global Presence: Established relationships with clients worldwide.

Customer-Centric: Focused on providing tailored solutions and exceptional service.

|

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM services to customize Lanthanum Doped Molybdenum Rod according to your specific requirements. From custom dimensions to specialized compositions, our team is equipped to deliver solutions that perfectly match your needs.

|

|

Frequently Asked Questions (FAQ)

1. What is the maximum diameter of these you can supply?

We offer rods with diameters up to 50 mm.

2. Can you produce rods with specific lengths?

Yes, we can provide rods with lengths up to 1500 mm.

3. What are the standard tolerances for these lanthanated molybdenum rod?

Our standard tolerance is ±0.05 mm.

4. How long does it take to process an order?

Lead times vary based on the order size and customization, typically ranging from 3 to 6 weeks.

5. How do you ensure the quality of these?

We conduct thorough quality checks at each stage of production to ensure compliance with industry standards.

Contact Us

Discover the exceptional performance of Shaanxi Peakrise Metal Co., Ltd.'s lanthanated molybdenum rods. Contact us today to discuss your requirements and receive a detailed quote.

Email: info@peakrisemetal.com

We look forward to working with you and providing top-quality solutions for your industrial needs.