silicon molybdenum rods heating element

Density: 5.6~5.8g/cm3

Operating Temperature: 1600~1800°C

Size: Φ3/6,Φ4/9,Φ5/10,Φ6/12,Φ9/18,Φ12/24 Etc.

Bending Strength: 20MPa(20℃)

HV: 570kg/mm2

Application: roller kilns, large muffle furnaces, box furnaces, and tube furnaces.

PRODUCT DESCRIPTION

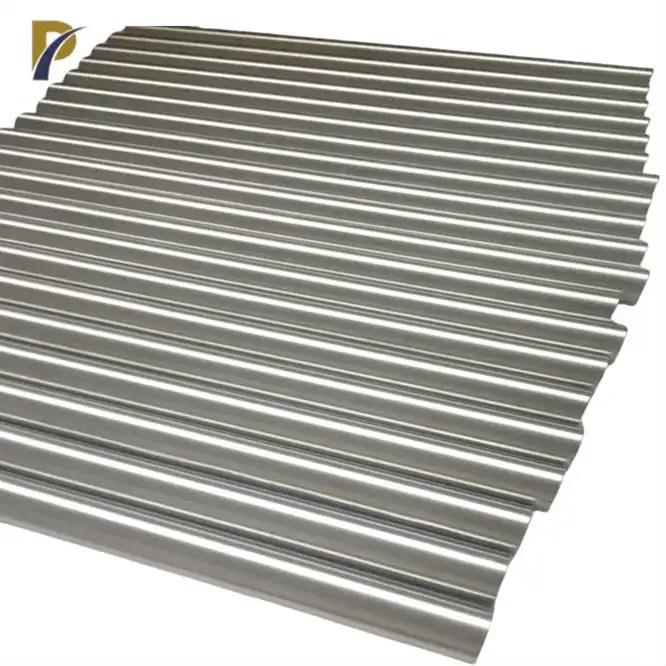

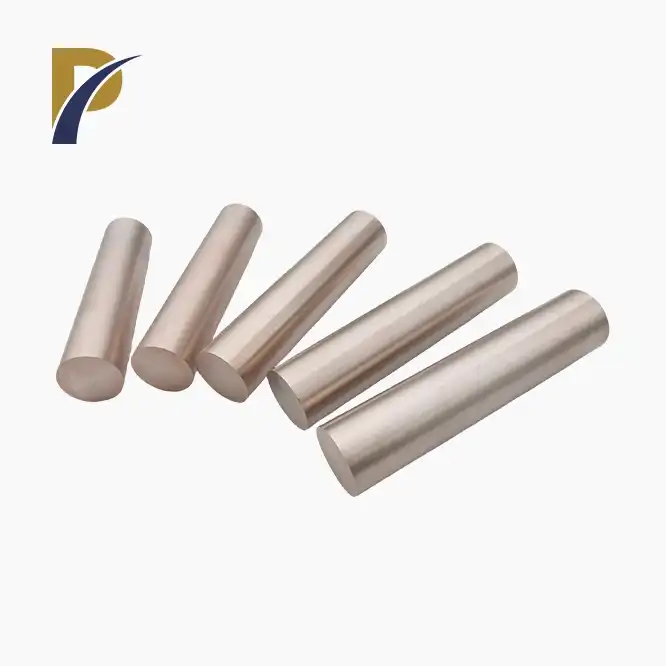

Silicon Molybdenum Rods Heating Element Product Introduction

Silicon molybdenum rods heating element (MoSi2 heating elements) are advanced, high-performance heating elements known for their exceptional resistance to oxidation and high-temperature stability. These elements are ideal for use in a variety of industrial furnaces and high-temperature processing applications.

Product Specifications

| Parameter | Details |

|---|---|

| Material Composition | Molybdenum Disilicide (MoSi₂) |

| Surface Coating | Silicon Dioxide (SiO₂) |

| Maximum Operating Temperature | 1800°C (3272°F) |

| Resistance | High resistance to oxidation |

| Density | 5.6 g/cm³ |

| Thermal Expansion Coefficient | 5 x 10⁻⁶ /°C |

| Heating Element Shape | Rod |

| Rod Diameter | Customizable (e.g., 3mm, 6mm, 9mm) |

| Rod Length | Customizable (e.g., 100mm, 200mm, 300mm) |

| Power Rating | Based on custom specifications |

| Applications | High-temperature furnaces, kilns, and other industrial heating processes |

| Connection Type | Clamp or screw connection |

| Installation Orientation | Horizontal or vertical |

| Service Life | Long-lasting, dependent on operating conditions |

| Operating Atmosphere | Suitable for air, nitrogen, and other non-reactive gases |

| Maintenance | Low maintenance requirement, with proper use |

| Packaging | Wooden crates with protective materials |

|

|

Physical and Chemical Properties

Silicon Molybdenum Heating Rod exhibit excellent oxidation resistance, high temperature stability, and mechanical strength, making them ideal for demanding heating environments.

|

|

Product Features

- High Temperature Stability: Operates effectively at elevated temperatures.

- Oxidation Resistance: Resists oxidation for prolonged lifespan.

- Uniform Heating: Ensures even heat distribution.

- Long Service Life: Durable construction for extended use.

Product Applications

- Industrial Furnaces: Used in heat treatment processes.

- Metallurgical Industries: Heating elements for smelting and refining.

- Glass Industry: Melting and shaping processes.

|

|

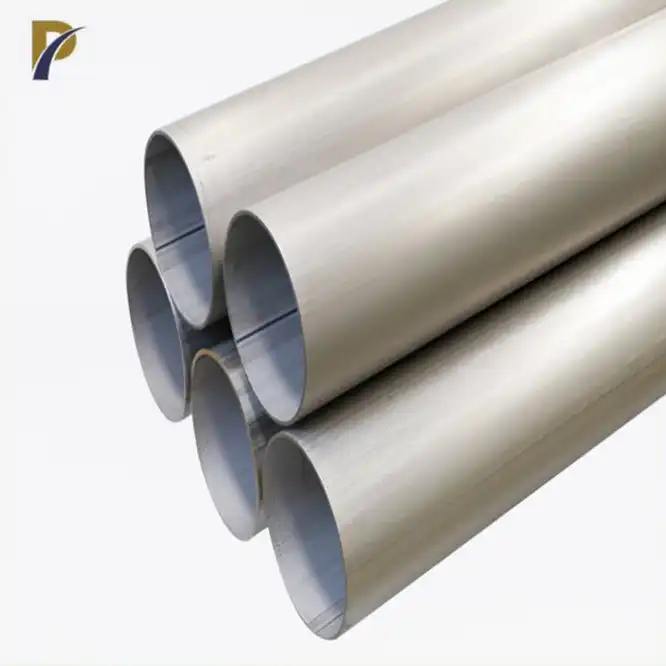

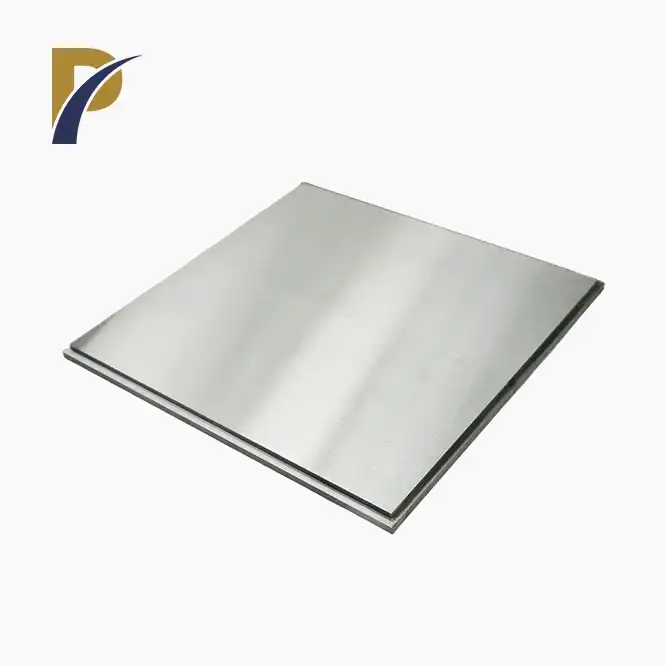

Manufacturing Process

In our manufacturing process, we leverage state-of-the-art facilities to uphold stringent quality standards and ensure precision throughout every stage of production. Central to our operations are intermediate frequency sintering furnaces, which play a critical role in the initial stages of forming materials. These furnaces utilize electromagnetic induction to heat powdered materials such as metals or ceramics to their sintering point, facilitating the creation of dense and uniform components with enhanced mechanical properties.

Additionally, our vacuum arc melting furnaces contribute significantly to our manufacturing capabilities. These furnaces create a controlled environment free from impurities, crucial for producing high-purity metals and alloys. Vacuum arc melting involves melting metal within a vacuum chamber, where the absence of oxygen prevents oxidation and ensures the integrity of the material's composition. This process results in materials that meet exacting standards for strength, conductivity, and corrosion resistance.

Complementing these capabilities is our precision machining equipment, essential for shaping and finishing components with exceptional accuracy. Our machining processes include CNC (Computer Numerical Control) machining, grinding, and polishing, enabling us to achieve tight tolerances and smooth surface finishes that meet or exceed industry requirements.

By integrating these advanced technologies and processes, we maintain a commitment to delivering silicon molybdenum rods heating element of superior quality and performance. Each step in our manufacturing process is meticulously executed to uphold reliability, durability, and consistency, meeting the diverse needs of our customers across various industries, from aerospace and automotive to electronics and beyond.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer of non-ferrous metal products, specializing in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, nickel alloys, and more.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging

- Wooden Crates: Secure packaging for long-distance transport.

- Cardboard Boxes: Lightweight and economical.

- Custom Packaging: Tailored to specific customer requirements.

Logistics

- Sea Freight: Cost-effective for bulk shipments.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Suitable for regional distribution.

- Express Services: Quick turnaround for smaller orders.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Industry Experience: Over a decade in non-ferrous metal production.

- Global Reach: Exported to multiple countries with established partnerships.

- Customization: Tailored solutions to meet specific customer needs.

- Quality Assurance: Rigorous testing and inspection protocols ensure superior product quality.

|

OEM Services

We offer comprehensive OEM services, providing customized solutions tailored to your exact specifications.

|

|

Frequently Asked Questions

-

What is the typical lifespan of your silicon molybdenum rods heating element?

- Our Silicon Molybdenum Heating Rod are designed for long-term use, with durability backed by rigorous testing.

-

Can you manufacture heating elements to custom dimensions?

- Yes, we specialize in customized production based on client requirements.

-

Do you provide technical support for installation and maintenance?

- Our team offers full technical assistance to ensure optimal performance of our products.

-

What certifications do your products meet?

- Our products adhere to international standards for quality and safety.

-

What is your production capacity?

- We have the capability to meet both small-scale and large-scale orders efficiently.

Call to Action

Contact us today to discuss your silicon molybdenum rods heating element requirements and explore how Shaanxi Peakrise Metal Co., Ltd. can support your industrial needs. Reach out to us at info@peakrisemetal.com.