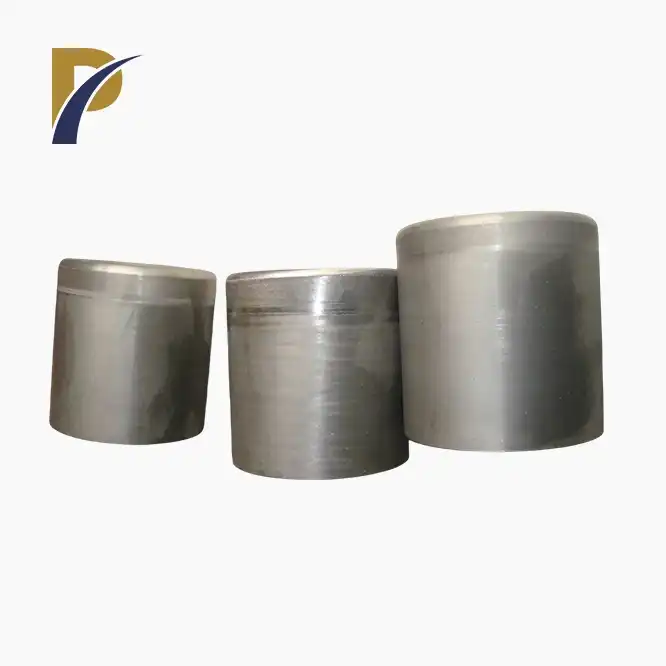

tungsten crucible for melting

Material: Pure Tungsten

Density: 17.8 G/cm3~19.3 G/cm3

Purity: 99.95%

Diameter: 30~500mm

Thickness:2~30mm

Height:<1000mm

Roughness:<1.6

Process method: Machining, sintering, welding

Application: vacuum coating industry, sintering furnace sintering, vacuum annealing industry.

PRODUCT DESCRIPTION

Tungsten Crucible for Melting Introduction

Tungsten crucible for melting are essential components in the high-temperature industry due to their extraordinary properties. Tungsten, with its exceptionally high melting point of 3422°C, is ideal for producing crucibles used in melting operations for various metals and materials. These crucibles are indispensable in industries such as aerospace, electronics, and advanced material manufacturing, where precision and durability are paramount.

Shaanxi Peakrise Metal Co., Ltd. is a renowned supplier of high-quality tungsten crucibles for melting. With extensive experience in producing non-ferrous metals, we have established ourselves as a trusted name in the global market.

Product Specifications

Below are the detailed specifications of our tungsten crucibles:

| Parameter | Value |

|---|---|

| Melting Point | 3422°C |

| Density | 19.3 g/cm³ |

| Purity | ≥ 99.95% |

| Maximum Working Temperature | 2800°C |

| Tensile Strength | 700-800 MPa |

| Diameter Range | 10-500 mm |

| Height Range | 10-600 mm |

| Parameter | Value |

|---|---|

| Electrical Resistivity | 5.5 μΩ·cm |

| Thermal Conductivity | 174 W/m·K |

| Coefficient of Thermal Expansion | 4.5 × 10⁻⁶ /K |

| Hardness | 89 HRA |

| Surface Roughness | ≤ 0.4 µm |

| Grain Size | ≤ 100 µm |

| Parameter | Value |

|---|---|

| Yield Strength | 600-700 MPa |

| Specific Heat Capacity | 0.134 J/g·K |

| Thermal Shock Resistance | Excellent |

| Machinability | Good |

| Oxidation Resistance | High |

| Corrosion Resistance | High |

|

|

Physicochemical Properties

Tungsten is known for its exceptional physicochemical properties that make it ideal for high-temperature applications. These properties include:

- High Melting Point: Tungsten has the highest melting point of all metals, making it perfect for use in extreme temperatures.

- Density: Tungsten's high density ensures stability and durability under high stress.

- Purity: Our tungsten crucibles boast a purity level of ≥ 99.95%, ensuring minimal contamination and optimal performance.

- Thermal Conductivity: Tungsten's excellent thermal conductivity facilitates efficient heat transfer during melting processes.

- Thermal Expansion: Low coefficient of thermal expansion reduces the risk of cracking under thermal stress.

- Electrical Resistivity: Tungsten's electrical resistivity ensures minimal energy loss in high-temperature electrical applications.

|

|

Tungsten Crucible for Melting Functions

Our Pure Tungsten Rod offers a range of functions, each derived from their unique properties:

- High-Temperature Resistance: Capable of withstanding temperatures up to 2800°C, ideal for melting refractory metals.

- Durability: High tensile strength and hardness ensure long service life and resistance to wear and deformation.

- Thermal Conductivity: Efficient heat distribution for uniform melting processes.

- Chemical Stability: High resistance to oxidation and corrosion, ensuring consistent performance in aggressive environments.

- Purity Assurance: Minimal impurity content prevents contamination of melted materials.

Product Applications

The unique functions of our tungsten crucibles extend to various high-value applications:

- Aerospace Industry: Used in the production of high-temperature alloys and superalloys essential for jet engines and spacecraft components.

- Electronics: Vital in the fabrication of semiconductor devices and the growth of single crystals for electronic applications.

- Advanced Materials: Crucial for the synthesis of high-purity materials and compounds in research and development settings.

- Medical Equipment: Employed in the manufacturing of medical devices that require high-temperature processing.

- Industrial Manufacturing: Integral to the production of high-performance industrial parts and tools requiring precise melting processes.

|

|

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd., we adhere to stringent manufacturing processes to ensure the highest quality of our tungsten crucibles:

- Raw Material Selection: We source the purest tungsten to guarantee product quality.

- Powder Metallurgy: Tungsten powder is compacted and sintered in high-temperature furnaces.

- Shaping: Advanced CNC machining techniques are used to achieve precise dimensions.

- Heat Treatment: Crucibles undergo heat treatment to enhance their mechanical properties.

- Quality Control: Each crucible is inspected for dimensional accuracy, purity, and surface finish.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts a state-of-the-art manufacturing facility equipped with a variety of advanced equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, plasma electron beam melting furnaces, and vacuum annealing furnaces. Our comprehensive setup allows us to maintain stringent quality control throughout the production process, ensuring that every tungsten crucible for melting meets our exacting standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Packaging Options

- Wooden Crates: Secure and sturdy for large shipments.

- Cardboard Boxes: Lightweight and suitable for smaller orders.

- Foam Inserts: Provide cushioning to prevent damage during transit.

- Waterproof Packaging: Protects against moisture and corrosion.

- Custom Packaging: Tailored solutions to meet specific customer needs.

- International Standards: Compliance with global packaging regulations.

Logistics Services

- Sea Freight: Economical option for large shipments.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Flexible and reliable for regional deliveries.

- Multimodal Transport: Combines different transportation methods for efficiency.

- Courier Services: Ideal for small and time-sensitive packages.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Extensive Experience: Over a decade of expertise in the non-ferrous metal industry.

- Comprehensive Product Range: Over 100 types of products, including various metal alloys.

- Global Reach: Exporting to multiple countries, with established long-term customer relationships.

- Quality Assurance: Rigorous testing and quality control processes.

- Advanced Manufacturing: Equipped with cutting-edge production and testing facilities.

- Customer-Centric Approach: Committed to providing high-quality products and services tailored to customer needs.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services. We support custom processing to meet your specific requirements, ensuring that our tungsten crucibles fit seamlessly into your unique applications. Whether you need specific dimensions, shapes, or additional features, our team is ready to collaborate with you to deliver bespoke solutions.

|

|

Frequently Asked Questions (FAQ)

-

What is the maximum temperature tungsten crucibles can withstand?

- High-strength tungsten Rod can withstand temperatures up to 2800°C, making them ideal for high-temperature applications.

-

What are the purity levels of your tungsten crucibles?

- Our tungsten crucibles have a purity level of ≥ 99.95%, ensuring minimal contamination.

-

Do you offer custom sizes for tungsten crucibles?

- Yes, we offer custom sizes and shapes to meet your specific requirements.

-

How do you ensure the quality of your tungsten crucible for melting?

- We follow stringent quality control processes, including material testing and precision machining, to ensure the highest quality.

-

What are the packaging options available for shipping?

- We offer various packaging options, including wooden crates, cardboard boxes, foam inserts, waterproof packaging, and custom solutions to ensure safe delivery.

Contact Us

We invite you to discover the exceptional quality and performance of our tungsten crucible for melting. As a global leader in non-ferrous metal production, Shaanxi Peakrise Metal Co., Ltd. is committed to providing high-quality products and services to meet your needs. Contact us today at info@peakrisemetal.com to discuss your requirements and learn more about how we can support your operations.

With our expertise and dedication, we are confident in our ability to deliver solutions that exceed your expectations. Partner with us for your tungsten crucible needs and experience the difference that quality and precision can make.

YOU MAY LIKE

-

VIEW MOREtungsten crucibles

VIEW MOREtungsten crucibles -

VIEW MOREhigh temperature furnace tungsten crucible

VIEW MOREhigh temperature furnace tungsten crucible -

VIEW MOREtungsten crucible for induction furnace

VIEW MOREtungsten crucible for induction furnace -

VIEW MOREmosi2 heating elements price

VIEW MOREmosi2 heating elements price -

VIEW MOREmolybdenum copper alloy heat sink

VIEW MOREmolybdenum copper alloy heat sink -

VIEW MOREtungsten sintering boat

VIEW MOREtungsten sintering boat -

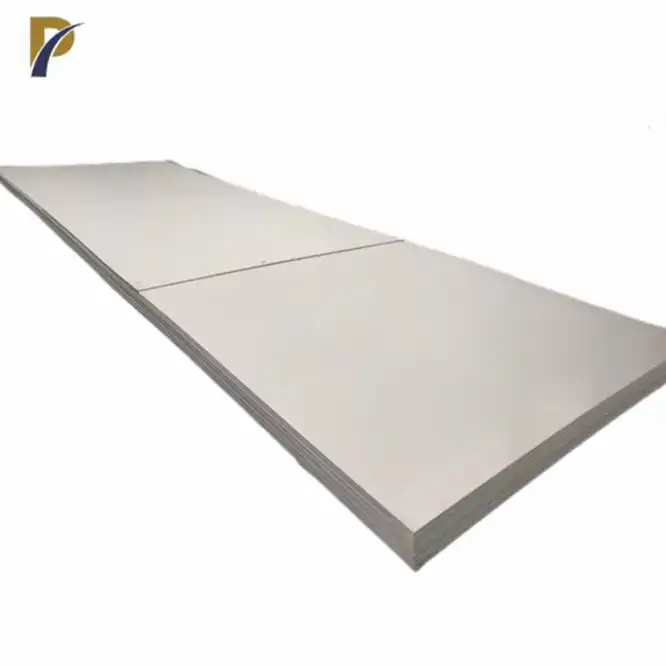

VIEW MOREtitanium plates

VIEW MOREtitanium plates -

VIEW MOREmolybdenum evaporation boats

VIEW MOREmolybdenum evaporation boats