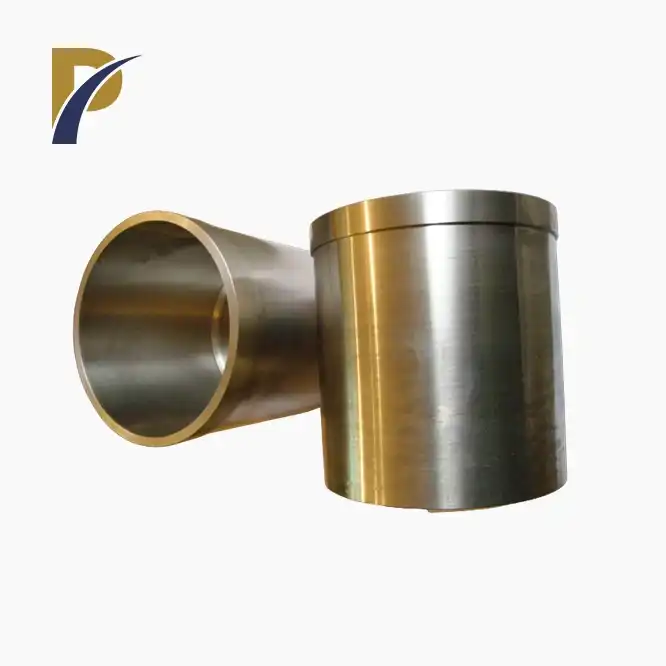

molybdenum crucibles

Purity: 99.95%

Density: 10.2g/cm3

Shape: Crucible

Diameter: Max.450mm

Height: Max.800mm

Finish: Ra<1.6

Craft: Sintering,Machined

Application: Metallurgical industry, rare earth industry, monocrystalline silicon, solar energy, artificial crystal and mechanical processing industries.

PRODUCT DESCRIPTION

Molybdenum Crucibles Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of molybdenum crucibles, designed for a wide range of high-temperature and demanding applications. the products are renowned for their exceptional thermal conductivity, high melting point, and resistance to chemical corrosion, making them ideal for use in metal processing, glass melting, and other high-temperature environments. Our crucibles are manufactured with precision to meet the rigorous standards of industries requiring reliable and durable components.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Molybdenum |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C (4748°F) |

| Purity | 99.95% |

| Diameter Options | 50 mm, 75 mm, 100 mm |

| Height Options | 50 mm, 75 mm, 100 mm |

| Wall Thickness | 2 mm, 3 mm, 4 mm |

| Maximum Temperature | 3000°C |

| Parameter | Value |

|---|---|

| Thermal Conductivity | 138 W/m·K |

| Electrical Resistivity | 5.2 x 10^-8 Ω·m |

| Expansion Coefficient | 4.8 x 10^-6 /K |

| Surface Finish | Polished or Customized |

| Customization | Available |

| Tolerance | ±0.1 mm |

| Parameter | Value |

|---|---|

| Application | Metal Processing, Glass Melting, Semiconductor Production |

| Size Customization | Available |

| Packaging Options | Wooden Crates, Custom Packaging |

| Shipping Methods | Sea Freight, Air Freight, Express Delivery |

|

|

Physical and Chemical Properties

Molybdenum crucibles from Shaanxi Peakrise Metal Co., Ltd. offer exceptional physical and chemical properties:

Thermal Conductivity: Molybdenum's high thermal conductivity ensures efficient heat transfer during high-temperature processes.

Electrical Resistivity: The low electrical resistivity of molybdenum makes it suitable for use in electric arc furnaces and other high-current applications.

Chemical Resistance: Sintered Molybdenum Crucibles resist corrosion and chemical attack from molten metals and reactive gases.

|

|

Molybdenum Crucibles Features

High Melting Point: With a melting point of 2620°C, the products maintain structural integrity at extreme temperatures, making them suitable for high-temperature applications.

Excellent Thermal Conductivity: Ensures efficient heat distribution, which is crucial for processes requiring precise temperature control.

Chemical Resistance: Resistant to oxidation and corrosion, ensuring long-lasting performance even in harsh environments.

Customization Options: Available in various sizes and configurations to meet specific application needs.

Molybdenum Crucibles Applications

Metal Processing: Ideal for melting and processing high-melting-point metals such as tungsten, platinum, and others in high-temperature environments.

Glass Melting: Used in the production of specialty glass and high-performance glass materials where high thermal stability is required.

Semiconductor Production: Crucibles are used in the manufacturing of semiconductor materials, where precise temperature control and chemical resistance are essential.

Advanced Materials: Suitable for use in the production of advanced materials and alloys requiring high-temperature processing.

|

|

Manufacturing Process and Production Flow

Material Preparation: High-purity molybdenum powder is prepared and refined to ensure maximum quality.

Forming and Shaping: The prepared molybdenum is shaped into crucibles using advanced pressing and sintering techniques.

Machining: Precision machining is employed to achieve the required dimensions and surface finish.

Quality Testing: Each crucible undergoes rigorous testing to ensure it meets our high standards for performance and reliability.

Finishing: Surface finishing options are applied based on customer requirements.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a comprehensive non-ferrous metal production enterprise with extensive experience in the manufacturing and processing of tungsten, molybdenum, tantalum, and other refractory metals. Our factory is equipped with advanced production equipment, including vacuum arc melting furnaces, laser cutters, and CNC machinery, to ensure the highest quality products.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

Wooden Crates: For secure and safe transportation of crucibles.

Custom Packaging: Tailored packaging solutions to meet specific requirements.

Foam Fillers: Added to prevent damage during shipping.

Waterproof and Moisture-Proof: Packaging to protect against environmental factors.

Shipping Methods

Sea Freight: Cost-effective for large shipments.

Air Freight: Faster delivery for urgent orders.

Land Transport: Reliable for regional deliveries.

Express Delivery: Quick service for smaller quantities.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Expertise and Experience: Over a decade of experience in producing high-quality non-ferrous metals.

Advanced Equipment: Utilization of state-of-the-art production machinery.

Global Reach: Products exported to multiple countries with established long-term relationships.

Quality Assurance: Rigorous testing and quality control processes.

Customization: Ability to meet specific customer requirements through tailored solutions.

|

OEM Services

We offer comprehensive OEM and ODM services, allowing customers to customize crucibles to their exact specifications. Whether you need specific sizes, designs, or packaging, Shaanxi Peakrise Metal Co., Ltd. is equipped to provide solutions that meet your unique needs.

|

|

FAQ

Q: What is the maximum temperature a molybdenum crucible can withstand?

A: High-Purity Molybdenum Crucibles can withstand temperatures up to 3000°C.

Q: Can you provide custom sizes and configurations?

A: Yes, we offer customization options for size, shape, and surface finish.

Q: How are the crucibles packaged for shipping?

A: Crucibles are packaged in wooden crates with foam fillers and waterproof materials to ensure safe delivery.

Q: What is the lead time for an order?

A: Lead time varies based on order size and customization requirements. Typically, it ranges from 2 to 4 weeks.

Q: Do you offer samples?

A: Yes, we can provide samples for evaluation upon request.

Contact Us

For more information on our molybdenum crucibles or to request a quote, please contact us at info@peakrisemetal.com. We look forward to assisting you with your high-quality molybdenum crucible needs and building a successful partnership.

YOU MAY LIKE

-

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator -

VIEW MOREsapphire crucible molybdenum

VIEW MOREsapphire crucible molybdenum -

VIEW MOREsic heating elements

VIEW MOREsic heating elements -

VIEW MOREtitanium pipe fittings flange

VIEW MOREtitanium pipe fittings flange -

VIEW MORElanthanated molybdenum plate

VIEW MORElanthanated molybdenum plate -

VIEW MOREmosi2 heating elements price

VIEW MOREmosi2 heating elements price -

VIEW MOREtantalum ro5200 wires

VIEW MOREtantalum ro5200 wires -

VIEW MOREmolybdenum sintering boats

VIEW MOREmolybdenum sintering boats