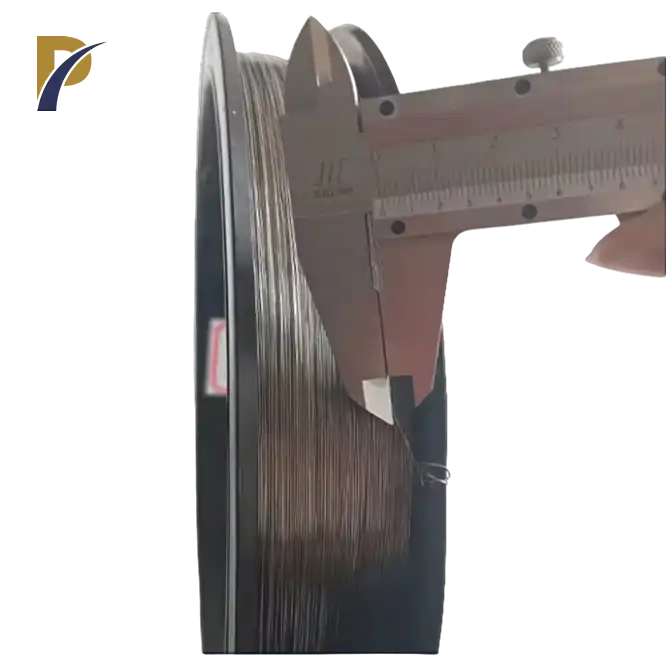

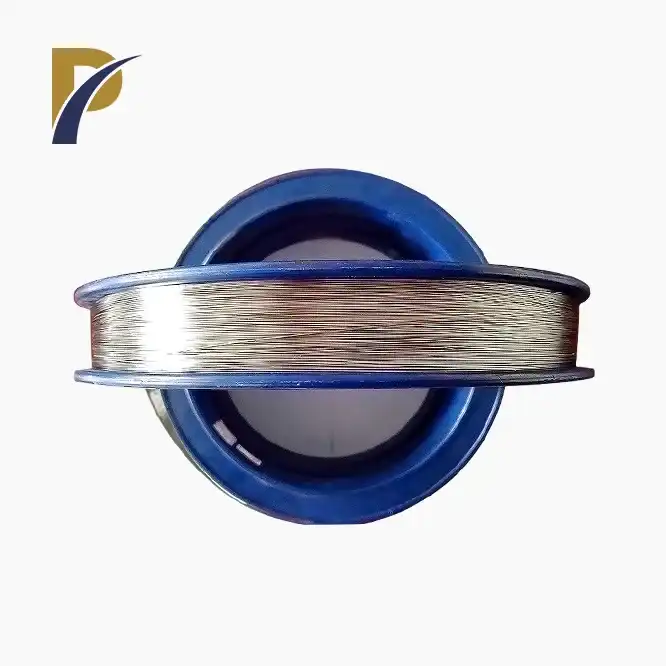

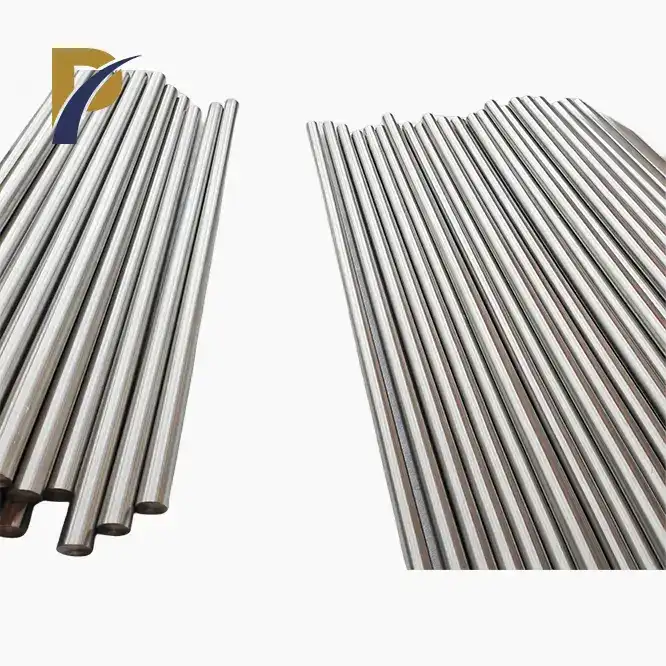

tantalum ro5200 wires

Purity:99.95%,99.99%

Grade:Ta1, Ta2,RO5200,RO5400

Surface:Bright

Diameter:0.1~4mm

Standard:ASTM B365

Leakage Current:≤0.10µA/cm2

Enable Current Density:5mA/cm2

Condition: annealed

Application:Mainly used for anode leads of tantalum electrolytic capacitors.

PRODUCT DESCRIPTION

Tantalum Ro5200 Wires Introduction

Your reliable supplier of tantalum RO5200 wires is Shaanxi Peakrise Metal Co., Ltd.. We are a leader in the production of non-ferrous metals and specialize in producing tantalum alloys of high quality that are tailored to meet the stringent requirements of various industries worldwide.

Product Specifications

| Property | Value |

|---|---|

| Material | Tantalum RO5200 |

| Diameter | Customizable |

| Purity | 99.95% min |

| Density | 16.6 g/cm³ |

| Melting Point | 2996°C |

| Tensile Strength | 207 MPa |

| Yield Strength | 138 MPa |

| Elongation at Break | 25% |

| Thermal Conductivity | 57.5 W/m·K |

| Electrical Conductivity | 27.6% IACS |

|

|

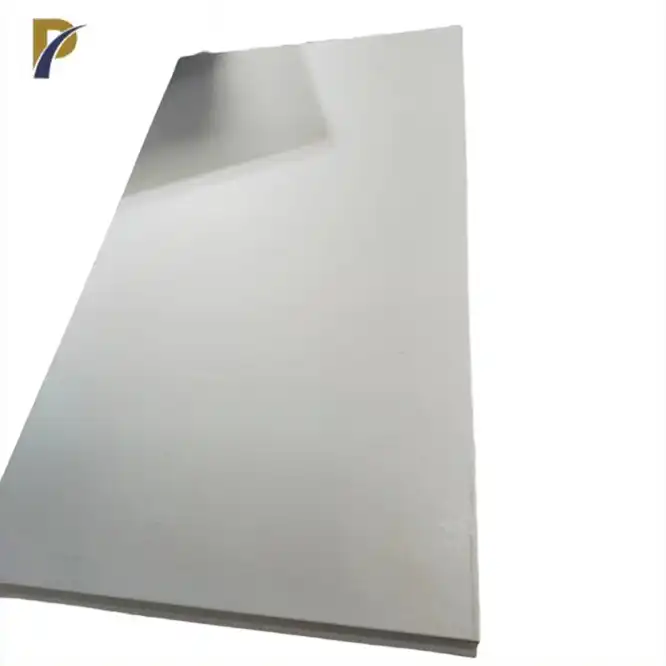

Physical and Chemical Properties

Tantalum RO5200 wires are ideal for applications in hostile environments where dependability is essential due to their high ductility and excellent resistance to corrosion. Its high liquefying point guarantees strength in outrageous warm circumstances.

|

|

Product Features

- Extraordinary consumption opposition in acidic conditions.

- Due to its high ductility, complex manufacturing procedures are possible.

- Better electrical and thermal conductivity

- Solid execution at raised temperatures.

Product Applications

1. Chemical Processing

Corrosion-Resistant Components: Used in the fabrication of valves, pumps, and other components in chemical plants where corrosive chemicals are processed.

Heat Exchangers: Tantalum wires are used in heat exchangers due to their resistance to corrosive fluids and high temperatures.

2. Electronics and Semiconductor Industry

Capacitors: Tantalum wires are used in the production of tantalum capacitors, which are essential in electronic devices for energy storage.

Wiring and Interconnects: Used in high-reliability electronic systems where resistance to corrosion and stable electrical properties are critical.

3. Medical Devices

Implants and Surgical Instruments: Tantalum's biocompatibility and corrosion resistance make it ideal for medical implants and surgical instruments.

Medical Imaging: Used in components for X-ray machines and other imaging equipment due to its high density and ability to absorb X-rays.

4. Aerospace and Defense

Aircraft Components: Tantalum wires are used in the construction of aircraft components that require high strength and resistance to extreme temperatures.

Missile Systems: Used in the fabrication of missile components due to its ability to withstand high temperatures and corrosive environments.

5. Nuclear Industry

Nuclear Reactors: Tantalum wires are used in the construction of nuclear reactor components due to their resistance to radiation and high temperatures.

Fuel Cells: Used in the development of fuel cells for their corrosion resistance and ability to operate at high temperatures.

6. Laboratory Equipment

High-Temperature Furnaces: Tantalum wires are used in the heating elements of high-temperature furnaces due to their high melting point and resistance to oxidation.

Scientific Instruments: Used in the construction of scientific instruments where high precision and durability are required.

7. Jewelry and Art

Custom Jewelry: Tantalum's unique properties and appearance make it a popular material for custom jewelry.

Artistic Creations: Used in artistic projects where a durable and corrosion-resistant material is needed.

8. Automotive Industry

High-Performance Engines: Tantalum wires are used in the construction of high-performance engine components that require high strength and resistance to heat.

Exhaust Systems: Used in exhaust systems where resistance to high temperatures and corrosion is essential.

|

|

Manufacturing Process

Our cutting-edge facilities at Shaanxi Peakrise Metal Co., Ltd. include vacuum arc melting furnaces, intermediate frequency sintering furnaces, and precision machining equipment. To guarantee consistent product excellence, strict quality control measures are adhered to at each production step.

|

|

|

Why Choose Us?

- Far reaching Ability: Over a decade of non-ferrous metal production experience.

- Worldwide Reach: Partnerships you can rely on in Taiwan, Ukraine, the United States, and elsewhere.

- Customization: tailored solutions to meet the particular needs of the client.

- Quality Control: Thorough testing and affirmations maintain worldwide norms.

|

OEM Services

We specialize in customizable solutions to meet unique client specifications, ensuring seamless integration into diverse applications.

FAQ

- What is the generally ordinary lead time for orders?

- Depending on the particulars of the order, lead times can range anywhere from two to six weeks.

- Yes, each shipment comes with complete material certifications.

- Do you offer sped up transportation choices?

- Indeed, we offer facilitated delivering for dire orders.

- What kinds of packaging do you provide?

- Wooden crates, cardboard boxes, and custom packaging options are available from us.

- Do your products meet international requirements?

- Absolutely, both ASTM and ISO standards are met or exceeded by our products.

|

|

Packaging

Our products are carefully packed to guarantee:

- protection from corrosion and moisture.

- adherence to international shipping regulations.

Logistics

We work with delivery through:

- Sea freight for bulk shipments at a reasonable cost.

- for deliveries that need to be made right away.

- Land and multimodal transport choices custom fitted to your necessities.

- For small, urgent orders, there are express courier services.

|

|

|

|

|

|

|

|

|

|

Contact Us

Please contact us at info@peakrisemetal.com if you have questions about tantalum RO5200 wires or if you have specific requirements. When you work with Shaanxi Peakrise Metal Co., Ltd., you'll get service and quality like no other.