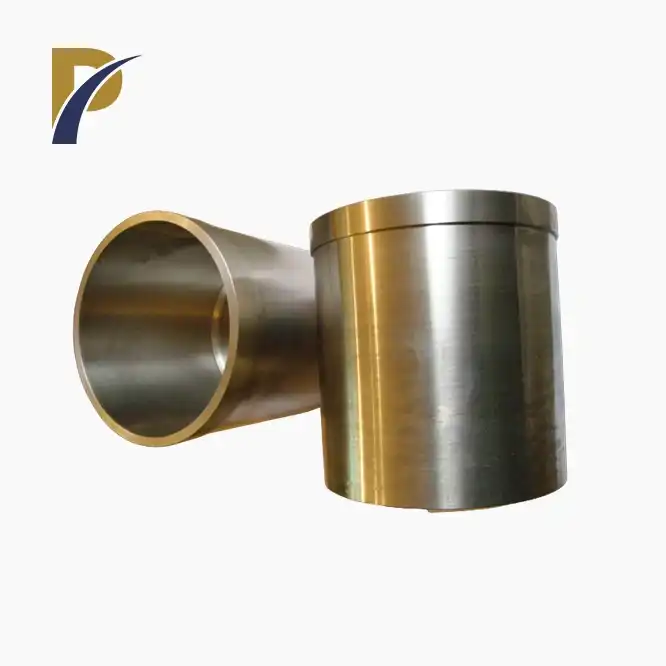

sapphire crucible molybdenum

Purity: 99.95%

Density: 10.2g/cm3

Shape: Crucible

Diameter: Max.450mm

Height: Max.800mm

Finish: Ra<1.6

Craft: Sintering,Machined

Application: Metallurgical industry, rare earth industry, monocrystalline silicon, solar energy, artificial crystal and mechanical processing industries.

PRODUCT DESCRIPTION

Sapphire Crucible Molybdenum Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd.'s product page for Sapphire Crucible Molybdenum. As a leading supplier in the industry, we specialize in providing high-quality non-ferrous metal products globally. Sapphire Molybdenum Crucibles are a critical component in various high-temperature applications due to its exceptional heat resistance and chemical stability.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Molybdenum |

| Purity | 99.95% min |

| Density | 10.2 g/cm³ |

| Melting Point | 2,623°C |

| Thermal Conductivity | 142 W/m·K |

| Coefficient of Thermal Expansion | 4.9 × 10⁻⁶/K |

|

|

Physical and Chemical Properties

The product exhibits high thermal conductivity, low thermal expansion, and excellent corrosion resistance, making it ideal for demanding industrial environments.

|

|

Sapphire Crucible Molybdenum Features

- High Temperature Resistance: With a melting point exceeding 2600°C, suitable for extreme heat applications.

- Chemical Inertness: Resistant to most acids and alkalis, ensuring longevity in harsh chemical environments.

- Uniform Heat Distribution: Ensures consistent heating and cooling cycles, crucial for semiconductor manufacturing.

- Precision Machining: Allows for complex designs and tight tolerances to meet specific customer requirements.

Product Applications

The utilization of sapphire crucible molybdenum spans across diverse industrial applications:

In the Semiconductor Industry, it plays a pivotal role in the cultivation of sapphire crystals essential for LEDs and advanced electronics. The robust properties of Molybdenum Sapphire Crucibles ensure the integrity and quality demanded by high-tech manufacturing processes.

Within Solar Energy, this material is integral to the fabrication of photovoltaic cells. Its resilience and stability make it ideal for withstanding the rigorous conditions of solar radiation, contributing to the efficiency and longevity of solar power systems.

In High-Temperature Furnaces, the product proves indispensable for the melting and casting of metals under extreme thermal conditions. Its ability to maintain structural integrity at high temperatures facilitates precise control over metallurgical processes, ensuring the production of high-performance alloys and materials.

These applications underscore the versatility and reliability of the product across cutting-edge industries, where its exceptional performance characteristics meet the stringent demands of modern technology and manufacturing standards.

|

|

Production Process

Our advanced manufacturing facilities include:

- Intermediate Frequency Sintering Furnace

- Vacuum Arc Melting Furnace

- Laser Cutter and Plasma Electron Beam Melting Furnace

- Comprehensive quality control ensures products meet international standards.

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art facility equipped with a range of production equipment and a dedicated R&D team committed to innovation.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging: We offer wooden crates, cardboard boxes, custom foam filling, and moisture-resistant packaging to ensure safe transit.

- Logistics: We provide sea, air, land, multimodal transport, and express delivery options for efficient global distribution.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Industry Experience: Over a decade of supplying high-quality non-ferrous metals globally.

- Customization: We offer OEM/ODM services to tailor products to specific client needs.

- Global Reach: Products are exported to over 10 countries, establishing long-term partnerships based on trust and quality.

|

|

OEM Services

We specialize in customizing molybdenum products to meet unique specifications, ensuring optimal performance for diverse applications.

|

|

FAQ

-

What is the maximum temperature the products can withstand?

- Sapphire Molybdenum Crucibles have a melting point of 2623°C, making it suitable for extremely high-temperature applications.

-

How is the purity of molybdenum ensured?

- We maintain a purity level of 99.95% through stringent quality control measures during production.

-

Can you customize shapes and sizes?

- Yes, we offer comprehensive customization services to meet specific client requirements.

-

What industries typically use the products?

- It is prominently used in semiconductor, solar, and high-temperature furnace industries.

-

How do you ensure product quality during transit?

- We use robust packaging and work closely with trusted logistics partners to ensure safe and timely delivery.

Contact us

Explore the superior quality and reliability of our sapphire crucible molybdenum. Contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com to discuss your requirements and initiate a partnership today.