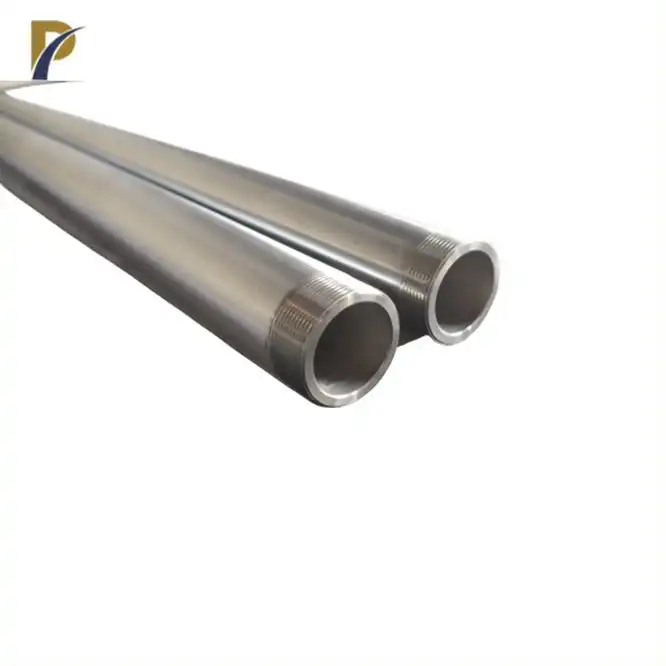

molybdenum tube target

Material: Molybdenum And Molybdenum Alloy

Purity: 99.95%

Density: 10.2g/cm3

Out Diameter: ≤250mm

Wall Thickness: 3~25mm

Length: ≤2700mm

Surface: Bright Advantage: Excellent electrical conductivity,Excellent thermal conductivity Application: electric vacuum industry,TFT-LCD industry.

PRODUCT DESCRIPTION

Molybdenum Tube Target Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your trusted supplier of high-quality molybdenum tube target. With extensive expertise in non-ferrous metal production, we offer products that meet the stringent demands of global markets.

Product Parameters

| Parameter | Value |

|---|---|

| Material | Molybdenum (Mo) |

| Purity | 99.95% min |

| Density | 10.2 g/cm³ |

| Dimensions | Custom sizes available |

| Surface Finish | Ground, polished |

| Thermal Conductivity | 138 W/m·K |

| Melting Point | 2,623°C (4,753°F) |

| Applications | Semiconductor, solar energy |

|

|

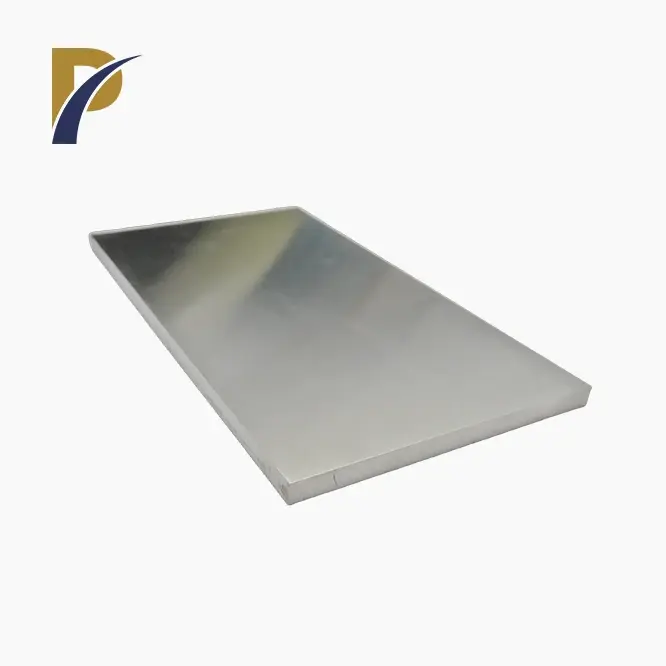

Physical and Chemical Properties

High-Purity Molybdenum Tube Targets exhibit high thermal conductivity, excellent corrosion resistance, and superior mechanical strength. They are characterized by their high melting point and stability in extreme environments.

|

|

Molybdenum Tube Target Functions

- Heat Dissipation: Efficiently transfers heat away from sensitive components.

- Material Purity: Ensures consistent performance in semiconductor manufacturing.

- Durability: Withstands high temperatures and chemical reactions.

- Precision Machining: Allows for complex shapes and sizes.

Molybdenum Tube Target Applications

These are essential in:

- Semiconductor deposition processes

- Thin film solar panel manufacturing

- Medical imaging equipment

- Aerospace components

The trend towards miniaturization and efficiency in technology further underscores the critical role of these in advanced industries.

|

|

Manufacturing Process

Peakrise Metal employs a cutting-edge manufacturing process that integrates advanced equipment to achieve superior precision and quality in every molybdenum tube target we produce. Central to our operations are vacuum arc melting furnaces, which play a pivotal role in the initial stages of material refinement. These furnaces create a controlled environment by melting molybdenum within a vacuum, preventing contamination and ensuring high purity. This process is essential for achieving materials with consistent chemical composition and exceptional mechanical properties, crucial for the performance of these.

|

|

|

Our Factory

With over a decade of experience, Shaanxi Peakrise Metal Co., Ltd. has evolved into a comprehensive non-ferrous metal production enterprise, committed to innovation and customer satisfaction.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

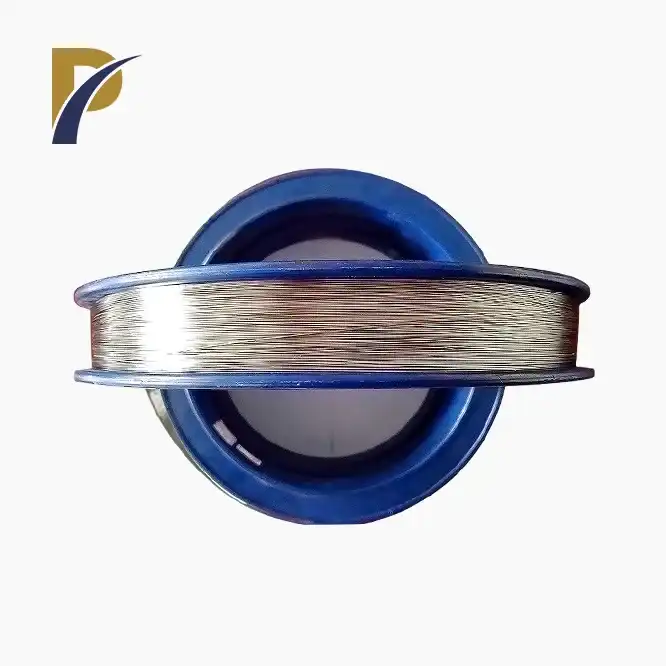

Packaging and Logistics

Packaging:

- Wooden crates

- Cardboard boxes

- Custom packaging solutions

Logistics:

- Sea freight

- Air freight

- Land transportation

- Express courier services

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Comprehensive Capabilities: From material research to product testing, we offer end-to-end solutions.

- Global Reach: Exporting to over 10 countries, we maintain long-term partnerships worldwide.

- Customization: Tailored solutions to meet specific customer requirements.

|

|

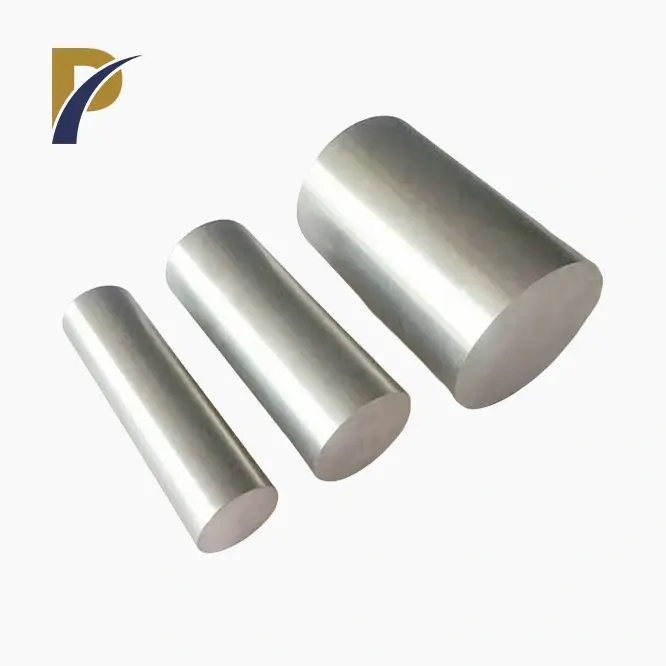

OEM Services

We specialize in OEM/ODM services, collaborating closely with clients to develop customized High-Purity Molybdenum Tube Targets that meet exact specifications.

|

|

FAQs

- What is the lead time for orders?

- Typically, 2-4 weeks depending on order size and customization.

- Can you provide samples for testing?

- Yes, we offer samples for evaluation upon request.

- What are your payment terms?

- Negotiable, generally including options for L/C and T/T.

- Do you have quality certifications?

- Yes, we are ISO 9001 certified.

- How do you ensure product quality?

- Rigorous testing procedures and quality control measures are implemented throughout production.

Contact us

Contact Us Ready to enhance your production capabilities with our premium molybdenum tube target? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com. Let's discuss how we can support your business needs!