nickel crucible 100ml

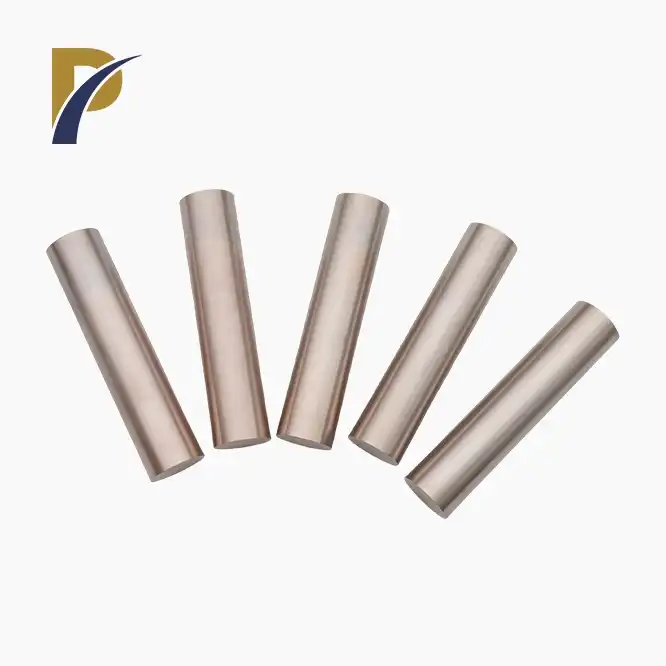

Grade: NO2200

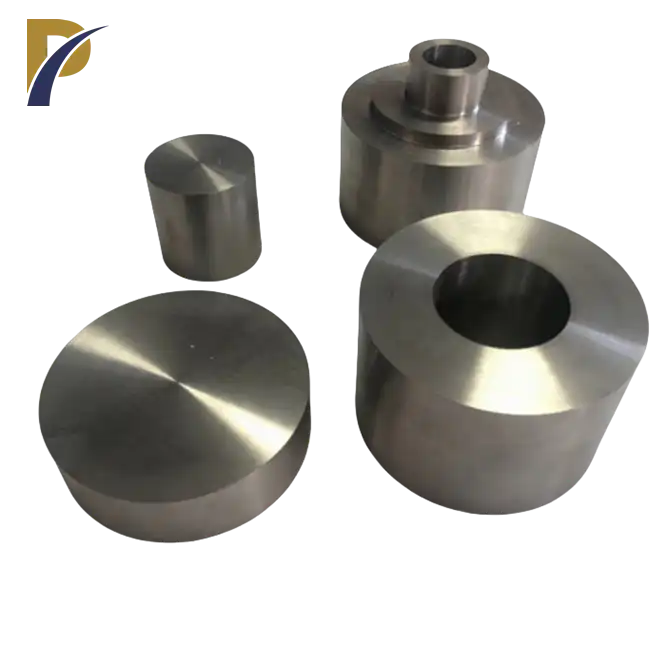

Shape: Crucible

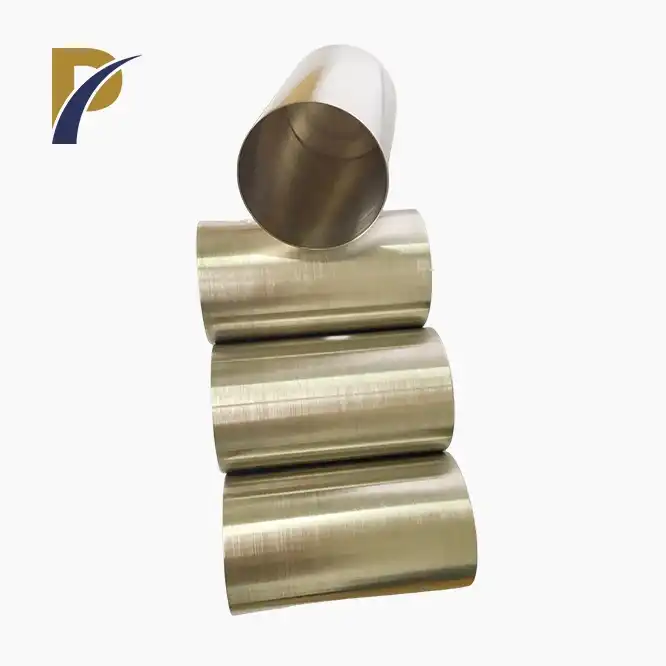

Type: Low Form Ni Crucible, Flanged Rims Ni Crucible,straight Wall Ni Crucible, Tapered Ni Crucible, Cylindrical Ni Crucible

Density: 8.9g/cm3

Size: 5ml,10ml,15ml,25ml,30ml,35ml,40ml,45ml Etc.

Custom: Yes

MOQ: 5pcs

Application: Molten ferroalloys, slag, clay, refractory materials

PRODUCT DESCRIPTION

Nickel Crucible 30ml Overview

Introducing the Nickel Crucible 30ml from Shaanxi Peakrise Metal Co.,Ltd. As a leading supplier in the non-ferrous metals industry, our products are crafted to meet the highest standards of quality and durability. The products are essential in various high-temperature applications due to their excellent resistance to corrosion and high melting points. Our products are specifically designed for laboratories and industrial processes that require precise measurements and reliable performance under extreme conditions.

Product Specifications

| Parameter | Specification |

|---|---|

| Material | Nickel (Ni) |

| Capacity | 30ml |

| Outer Diameter | 40mm |

| Height | 50mm |

| Wall Thickness | 1.5mm |

| Melting Point | 1455°C |

| Purity | ≥99.5% |

|

|

Physical and Chemical Properties

- Density: 8.9 g/cm³

- Melting Point: 1455°C

- Boiling Point: 2730°C

- Thermal Conductivity: 90.9 W/m·K

- Electrical Resistivity: 69.3 nΩ·m

|

|

Nickel Crucible 100ml Functions

- High-Temperature Resistance: With a melting point of 1455°C, our nickel crucible 100ml can withstand extreme heat, making them ideal for high-temperature applications.

- Corrosion Resistance: Nickel's inherent resistance to oxidation and corrosion ensures long-term durability in harsh environments.

- Chemical Stability: The high purity of our products provides excellent chemical stability, crucial for precise and uncontaminated reactions.

- Thermal Conductivity: Superior thermal conductivity ensures even heat distribution, enhancing the efficiency of melting and heating processes.

Product Applications

- Laboratory Use: nickel crucible 100ml is perfect for high-temperature chemical reactions, material synthesis, and metal analysis.

- Industrial Processes: Essential in processes such as melting, refining, and alloying metals.

- Research and Development: Used in advanced R&D settings to develop new materials and study high-temperature properties.

- Educational Institutions: Utilized in universities and technical colleges for teaching and demonstration purposes.

|

|

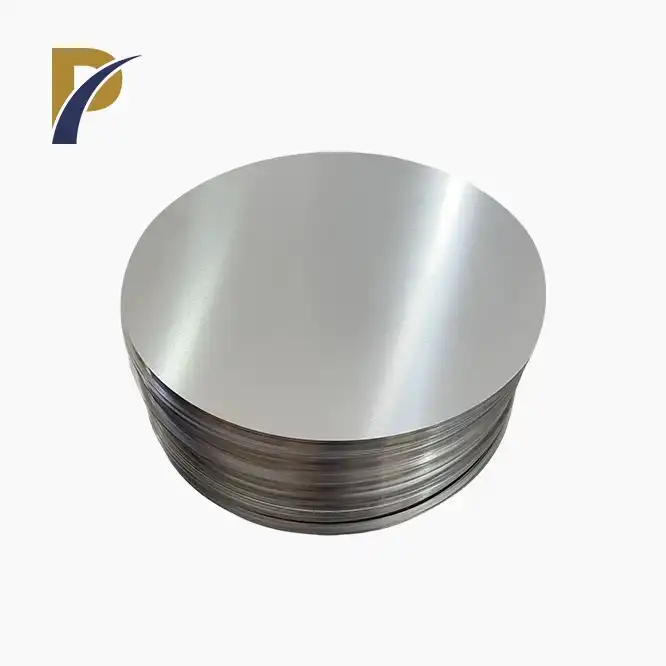

Production Process and Technology

Our nickel crucible 30ml are manufactured using advanced production techniques to ensure superior quality:

- Material Selection: High-purity nickel is selected and tested for consistency.

- Melting and Casting: Nickel is melted in a vacuum arc melting furnace to eliminate impurities and then cast into molds.

- Machining: Precision machining processes ensure each product meets exact specifications.

- Annealing: The products are annealed in a vacuum furnace to enhance mechanical properties and reduce stress.

- Inspection: Rigorous quality control checks are conducted to ensure every product meets industry standards.

|

|

|

About Our Factory

Shaanxi Peakrise Metal Co.,Ltd boasts state-of-the-art facilities equipped with the latest technology:

- Intermediate Frequency Sintering Furnace

- Vacuum Arc Melting Furnace

- Laser Cutter

- Plasma Electron Beam Melting Furnace

- Vacuum Annealing Furnace

- Various Rolling Mills and Wire Drawing Machines

- Plasma Welding Rooms and CNC Machinery

Our advanced equipment and skilled workforce enable us to produce high-quality non-ferrous metal products that meet the stringent requirements of our global customers.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Packaging Options:

- Wooden Box Packaging

- Carton Packaging

- Foam-filled Packaging

- Waterproof and Moisture-proof Packaging

- Custom Packaging

- Packaging compliant with international standards

Logistics Options:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Express Delivery Services

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Rich Experience: Over a decade of experience in producing and exporting non-ferrous metal products.

- High-Quality Standards: Commitment to delivering products that meet and exceed industry standards.

- Advanced Manufacturing: Equipped with cutting-edge technology and skilled personnel.

- Comprehensive Services: From material research and development to product testing and stock inventory.

- Global Reach: Products exported to multiple countries with established long-term cooperative relationships.

- Customer Satisfaction: High recognition and evaluation from customers worldwide.

|

OEM/ODM Services

Shaanxi Peakrise Metal Co.,Ltd offers comprehensive OEM/ODM services to meet your specific requirements. Whether you need custom sizes, shapes, or compositions, our team is equipped to provide tailored solutions. Partner with us for bespoke nickel crucibles that match your unique needs.

|

|

Frequently Asked Questions (FAQ)

-

What is the purity of the nickel used in the crucibles?

- Our products are made from nickel with a purity of ≥99.5%.

-

Can you produce custom-sized nickel crucibles?

- Yes, we offer OEM services and can manufacture crucibles to your specifications.

-

What is the typical lead time for an order?

- Lead time varies depending on the order size and specifications, but typically ranges from 2 to 4 weeks.

-

Do you provide samples for testing?

- Yes, we can provide nickel crucible 100ml samples for testing purposes upon request.

-

How are the crucibles packaged for shipment?

- The products are securely packaged using foam-filled, waterproof, and moisture-proof packaging, with options for wooden box or carton packaging.

Contact Us

Are you ready to enhance your high-temperature processes with premium nickel crucible 100ml? Contact Shaanxi Peakrise Metal Co.,Ltd today at info@peakrisemetal.com to learn more about our products and services.