Zr 702 cylindrical zirconium crucible

Name: ICP-OES Laboratory Purification Zirconium Crucible

Material: Zirconium & Zirconium Alloy

Grade: Zr702,Zr705,R60001,R60901

Shape: Crucible

Type: Low Form Zirconiu Crucible, Flanged Rims Zirconium Crucible,straight Wall Zirconium Crucible, Tapered Zirconium Crucible, Cylindrical Zirconium Crucible

Density: 6.51g/cm3

Size: 5ml,10ml,15ml,25ml,30ml,35ml,40ml,45ml Etc.

Custom: Yes

MOQ: 5pcs

Advantage: Corrosion Resistant, Good Mechanical Strength At High Temperatures

PRODUCT DESCRIPTION

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is a trusted supplier of high-quality cylindrical zirconium crucibles, essential for industries that require superior heat resistance, corrosion resistance, and durability. Zirconium crucibles are widely used in high-temperature and corrosive environments such as chemical processes, metallurgy, and nuclear industries, due to their remarkable properties. Zirconium’s high melting point and resistance to corrosive materials make it ideal for applications involving extreme conditions, ensuring stability and longevity.

As a premier manufacturer of zirconium crucibles, Shaanxi Peakrise Metal Co., Ltd. brings years of experience in producing non-ferrous metal products. We offer customization options to meet various industry needs and provide tailored solutions to ensure our clients' operations run smoothly. Our zirconium crucibles are precisely engineered to meet the most stringent specifications, making them reliable and efficient for various applications.

| Name: | Zr 702 cylindrical zirconium crucible |

| Material: | Zirconium & Zirconium alloy |

| Grade: | Zr702,Zr705,RO60001,RO60901 |

| Density: | 6.51g/cm3 |

| Shape: | Crucible |

| Type: | Low form zirconiu crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible |

| Volume: | 5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc, |

| Custom: | Yes, process as per customer's drawing. |

| Surface: | Bright |

| MOQ: | 1pc |

|

|

Product Parameters Table

| Parameter | Value |

|---|---|

| Material | Pure Zirconium 702 |

| Melting Point | 1855°C |

| Density | 6.51 g/cm³ |

| Diameter Range | 10 mm - 500 mm |

| Height Range | 20 mm - 1000 mm |

| Wall Thickness | 1 mm - 10 mm |

| Surface Treatment | Polished, Sandblasted |

Physical and Mechanical Properties

Zirconium crucibles boast outstanding physical and mechanical properties that make them indispensable in extreme environments. Their high melting point of 1855°C and superior corrosion resistance ensure performance stability in aggressive chemical conditions. The tensile strength of 330 MPa and a yield strength of 275 MPa provide these crucibles with the toughness needed for long-term industrial use. In addition, their excellent thermal conductivity and low thermal expansion make them suitable for high-precision applications.

Chemical Content :

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

Product Functions

- Heat Resistance: Zirconium crucibles are designed to withstand extremely high temperatures, making them ideal for processes that involve high thermal demands.

- Corrosion Resistance: These crucibles resist corrosion from a wide range of chemicals, acids, and alkalis, ensuring longevity and reliable operation in harsh environments.

- Durability: With high tensile and yield strength, zirconium crucibles are durable and can endure repeated cycles of heating and cooling without significant wear.

- Precision in Applications: The low thermal expansion coefficient ensures minimal distortion under thermal stress, providing precision in temperature-sensitive processes.

Product Applications

- Metallurgy: Cylindrical zirconium crucibles are crucial in the smelting and refining of metals, especially in high-temperature environments where purity and heat resistance are critical.

- Chemical Processing: The superior corrosion resistance of zirconium crucibles allows their use in chemical plants, where exposure to aggressive acids and bases is common.

- Nuclear Industry: Thanks to zirconium’s low neutron absorption cross-section, zirconium crucibles are ideal for nuclear reactors and laboratories requiring materials with minimal radiation interaction.

- Aerospace and Defense: In aerospace, these crucibles are used for high-precision melting of alloys and other materials, benefiting from their excellent thermal conductivity and mechanical strength.

- Glass and Ceramics: The ceramics industry employs zirconium crucibles for melting materials in the production of high-purity glass and ceramics.

|

|

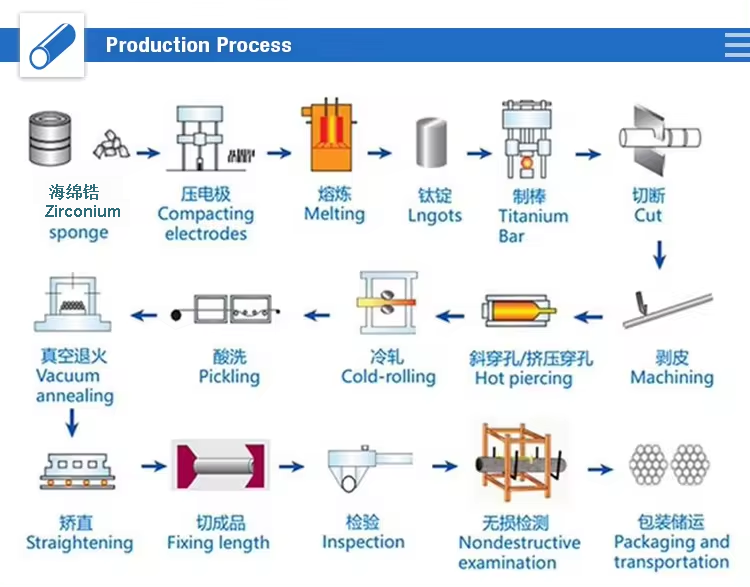

Product Process and Production Flow

- Material Selection: We start by selecting high-purity zirconium 702, known for its excellent performance in demanding environments.

- Forming: Using state-of-the-art forging and rolling processes, we shape the zirconium into cylindrical forms, ensuring consistent wall thickness and dimensions.

- Sintering: The crucibles are sintered in vacuum furnaces at controlled temperatures to optimize density and strength.

- Surface Treatment: The crucibles undergo surface treatments such as polishing or sandblasting to meet specific application requirements.

- Inspection: Each crucible is rigorously inspected for dimensional accuracy and surface quality to ensure it meets our high standards.

- Packaging and Dispatch: Finally, the crucibles are carefully packed and prepared for global shipment.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a modern production facility equipped with advanced equipment such as vacuum arc melting furnaces, laser cutters, and CNC machines. We have over 10 years of experience in non-ferrous metal manufacturing and supply, with a focus on delivering the highest quality zirconium products. Our facility is ISO 9001 certified, and we maintain strict quality control throughout every stage of production.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Crate Packaging: For heavy and large crucibles, we use durable wooden crates to ensure safe transit.

- Foam-filled Packaging: To prevent damage during transport, crucibles are carefully packed with foam inserts for cushioning.

- Waterproof and Moisture-proof Packaging: Ensures that the crucibles are protected from environmental factors during long-distance shipping.

- Custom Packaging: We offer tailored packaging solutions based on the specific needs of our clients.

- International Standard Packaging: Our packaging conforms to international shipping regulations to ensure smooth customs clearance and delivery.

|

|

Logistics Options

- Sea Freight: Ideal for bulk orders with cost-effective rates.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Available for regional clients.

- Multimodal Transport: Combined transport solutions to suit different delivery requirements.

- Courier Services: For smaller, high-priority shipments.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Extensive Industry Experience: Over a decade of experience in producing and exporting non-ferrous metals, particularly zirconium products.

- Advanced Technology: State-of-the-art production equipment ensures precision and high-quality output.

- Customization: We offer OEM/ODM services, allowing us to meet specific customer requirements.

- Global Reach: Our products are exported to over 10 countries, with strong client relationships across various industries.

- High-Quality Standards: All processes adhere to ISO 9001 standards, guaranteeing consistency and reliability.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we support custom designs and specifications for zirconium crucibles. Our skilled R&D team works closely with clients to develop solutions that fit their unique operational needs. Whether you require specific dimensions, surface finishes, or technical attributes, we are equipped to provide tailored products that meet exact industry standards.

|

|

-

What are the main benefits of using zirconium crucibles?

Zirconium crucibles offer excellent heat and corrosion resistance, making them ideal for high-temperature and aggressive chemical environments. -

Can you customize the crucible dimensions?

Yes, we offer full customization options, including size, thickness, and surface treatments, to meet specific client needs. -

What industries commonly use zirconium crucibles?

Zirconium crucibles are widely used in metallurgy, chemical processing, nuclear applications, and aerospace. -

How are the crucibles inspected before delivery?

Each crucible undergoes rigorous dimensional and surface quality checks to ensure compliance with client specifications. -

What is the typical lead time for an order?

Lead times vary depending on order size and customization, but we strive to deliver within 4-6 weeks for most orders.

Contact Us

We invite global purchasers to explore the high-quality cylindrical zirconium crucibles offered by Shaanxi Peakrise Metal Co., Ltd. For inquiries, please feel free to contact us at info@peakrisemetal.com. We look forward to collaborating with you and providing solutions tailored to your industry needs.