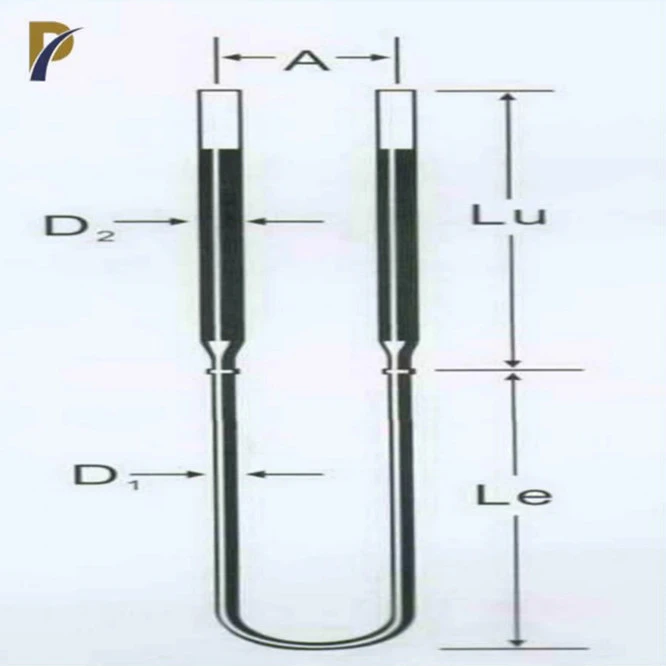

U type sic heater element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction for SiC Heater Elements by Shaanxi Peakrise Metal Co., Ltd.

Silicon molybdenum rod electric heating element is a resistance heating element based on molybdenum silicide. When the sintered molybdenum silicide product is heated to a high temperature in an oxidizing atmosphere, a dense quartz glass film is formed on its surface, which can keep the product from oxidizing. Therefore, silicon molybdenum rod elements have unique high-temperature oxidation resistance. The maximum operating temperature in an oxidizing atmosphere is 1750℃. The resistance of silicon molybdenum rod elements does not change with the length of use (resistance increases with increasing temperature), that is, it does not age, so new and old elements can be mixed. The mechanical properties of silicon molybdenum rod elements are the same as other ceramic products. At room temperature, they are brittle materials and are easy to break, but this can be avoided with proper use and reasonable installation.

U-shaped silicon molybdenum rod is the most commonly used specification among silicon molybdenum rod electric heating elements. In electric heating equipment, the element is suspended vertically by a supporting chuck to avoid adding mechanical stress to the heating end of the element, otherwise it is easy to cause the element to break.

Shaanxi Peakrise Metal Co., Ltd., a leading supplier of SiC heater elements, brings over a decade of experience in non-ferrous and refractory metal production to the global market. Our SiC elements are meticulously manufactured using advanced techniques to ensure top-tier performance in a wide range of industrial applications. We offer customized designs to meet specific client requirements, helping industries achieve optimal heating solutions with products that exceed international standards. As a global supplier, we serve markets across North America, Europe, and Asia, providing efficient, reliable, and cost-effective solutions for high-temperature heating needs.

|

|

Product Parameters

| Parameter | Value |

|---|---|

| Maximum Operating Temperature | 1600°C |

| Resistance Range | 0.1-50Ω |

| Length | 300-1800mm |

| Diameter | 12-54mm |

| Heating Zone Length | 100-1500mm |

| Parameter | Value |

|---|---|

| Power Density | 50-150 W/cm² |

| Voltage Range | 20-480V |

| Current Range | 1-40A |

| Hot Zone Temperature | 1350°C |

| Cold End Length | 150-300mm |

Physical and Mechanical Properties

Silicon carbide heater elements exhibit several key physical and mechanical properties that make them ideal for high-temperature environments:

- High Thermal Conductivity: SiC offers excellent heat conduction, ensuring even distribution of heat across the element.

- Oxidation Resistance: The material resists degradation in oxidizing environments, prolonging the service life of the element.

- Mechanical Strength: With a flexural strength of 35 MPa, SiC heater elements can withstand physical stress during high-temperature applications.

- Thermal Shock Resistance: These elements are capable of withstanding sudden changes in temperature, minimizing the risk of failure during rapid heating and cooling cycles.

- Corrosion Resistance: SiC elements are resistant to most chemical environments, making them suitable for various industrial processes.

Product Functions

- Precision Heating: SiC elements provide highly controlled and uniform heat distribution, essential for processes requiring exact temperature maintenance.

- Energy Efficiency: These elements operate at high power densities, reducing energy consumption while maintaining high output.

- Durability: The inherent resistance to oxidation and corrosion increases the lifespan of the elements, reducing downtime and maintenance costs.

- Flexibility: Available in a wide range of sizes and configurations, SiC heater elements can be customized to meet specific process requirements.

|

|

Product Applications

SiC heater elements are used in various industries due to their versatility and efficiency. Here are some key applications:

- Ceramics Industry: Used in kilns and furnaces for firing ceramics, these elements ensure uniform heat distribution and precise temperature control.

- Glass Manufacturing: SiC elements are used for heating glass during production, providing consistent heat essential for high-quality glass products.

- Heat Treatment: In metalworking, SiC heater elements are used in furnaces for processes such as annealing, hardening, and tempering, where accurate temperature control is vital.

- Semiconductor Manufacturing: The high thermal conductivity of SiC elements makes them suitable for processes in the semiconductor industry, where stable and reliable heating is required.

- Chemical Processing: SiC elements resist chemical corrosion, making them ideal for heating chemical solutions and compounds in industrial settings.

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates an advanced production facility equipped with state-of-the-art machinery, including vacuum arc melting furnaces, CNC machines, and laser cutters. Our factory is capable of producing high-quality non-ferrous metal products and specializes in meeting the custom needs of our global clients. With a robust quality control system in place, we ensure that every product leaving our facility meets the highest standards of excellence.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Box Packaging: For heavy or bulk orders requiring sturdy and reliable packaging.

- Carton Packaging: Suitable for smaller shipments or individual units.

- Foam-filled Packaging: Ensures protection against impact during transportation.

- Waterproof and Moisture-proof Packaging: Prevents damage due to environmental conditions.

- Custom Packaging: Tailored to meet the specific requirements of the product and client.

- International Standard Packaging: Complies with global shipping regulations and standards.

Logistics

- Sea Freight: Cost-effective option for large-volume orders.

- Air Freight: Ideal for urgent or smaller shipments requiring quick delivery.

- Land Transport: Efficient for domestic and regional deliveries.

- Multimodal Transport: Combines different modes of transportation for optimal efficiency.

- Courier Services: For fast, smaller shipments requiring door-to-door service.

|

|

|

|

|

|

|

|

|

|

Why Choose Us

- Comprehensive Product Range: We offer over 100 types of non-ferrous and refractory metal products, including SiC heater elements.

- Advanced Manufacturing: Equipped with the latest technology, we ensure precision and quality in every product we produce.

- Global Reach: With exports to multiple countries, we have established strong, long-term relationships with clients worldwide.

- Custom Solutions: Our OEM services cater to the specific needs of clients, offering tailor-made solutions for various industrial applications.

- Expertise and Experience: With over a decade of experience in the industry, our team is committed to delivering high-quality products backed by professional expertise.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers customized SiC heater elements tailored to meet specific process requirements. Our team works closely with clients to design, manufacture, and deliver custom heating solutions that align with their unique operational needs. We support both OEM and ODM services, ensuring that each product is produced to exact specifications.

|

|

FAQ

-

What is the maximum operating temperature of SiC heater elements?

SiC heater elements can operate at temperatures up to 1600°C. -

Are SiC elements resistant to chemical corrosion?

Yes, they are highly resistant to most chemicals, making them suitable for harsh industrial environments. -

Can you provide custom sizes and configurations?

Yes, we offer a range of custom sizes and configurations to meet specific application needs. -

What industries are SiC heater elements commonly used in?

SiC heater elements are widely used in ceramics, glass manufacturing, heat treatment, and semiconductor industries. -

How do I place an order for custom SiC heater elements?

You can contact us directly at info@peakrisemetal.com to discuss your specific requirements.

Contact Us

For more information about our SiC heater elements or to place an order, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. We welcome global purchasers to explore our wide range of high-quality non-ferrous metal products and customized solutions. Let’s work together to create efficient and reliable heating solutions for your industry needs.

This content provides a professional and comprehensive overview of SiC heater elements, aligned with SEO best practices and tailored to attract and convert global customers.