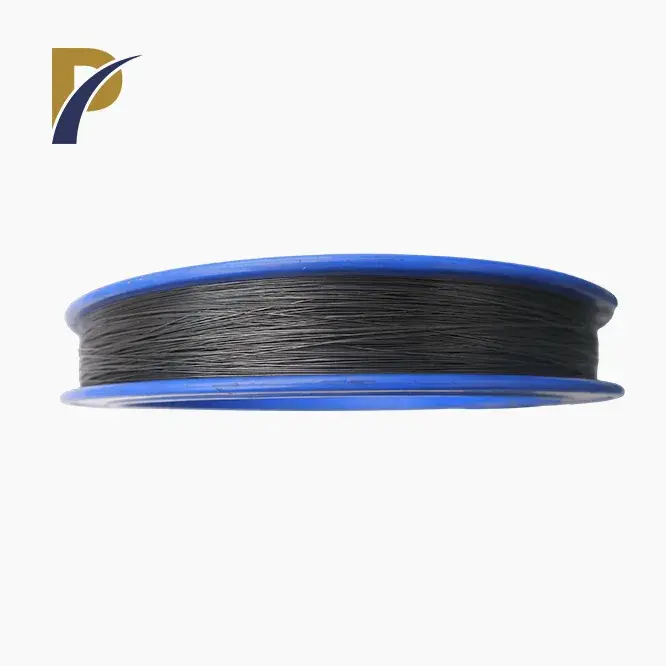

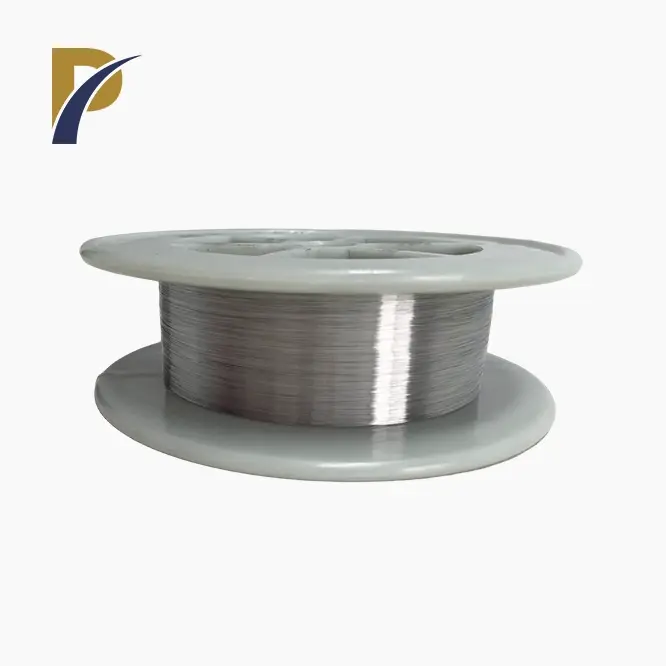

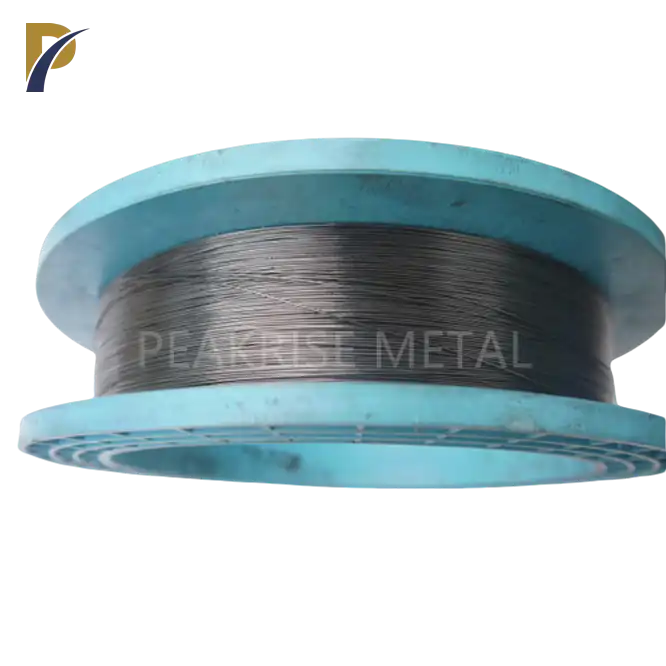

molybdenum wire for wire winding core wire hanger molybdenum lead wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

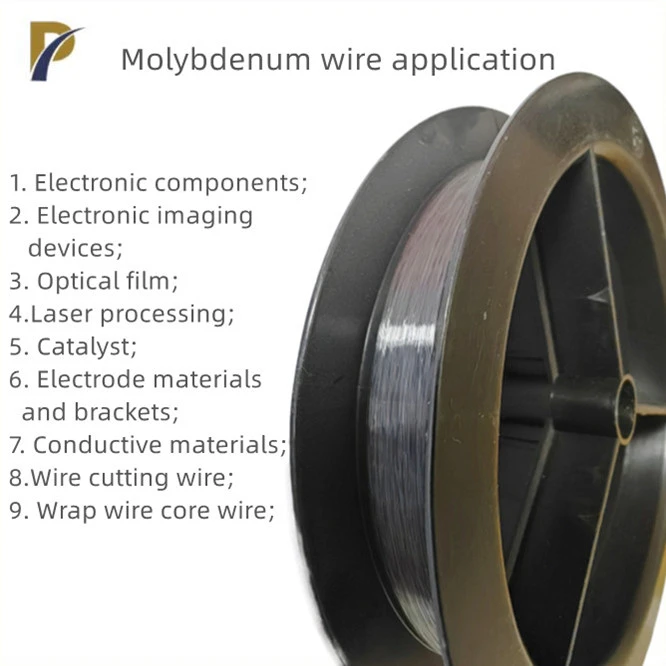

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Product Introduction:

Welcome to Shaanxi Peakrise Metal Co., Ltd., a leading supplier of high-quality molybdenum wire. Our company specializes in the production of non-ferrous metals and their alloys, including molybdenum, which are crucial in various industrial applications. With years of expertise and a commitment to excellence, we provide top-grade wire products that meet stringent industry standards.

Our molybdenum wires are known for their exceptional purity, strength, and durability. These wires are used extensively in aerospace, electronics, and high-temperature applications due to their superior performance and resistance to extreme environments. At Shaanxi Peakrise Metal Co., Ltd., we leverage advanced manufacturing technologies and stringent quality control measures to ensure that our products consistently meet the highest standards of quality.

Product Parameters

| Parameter | Titanium Wire | Molybdenum Wire |

|---|---|---|

| Diameter (mm) | 0.1 - 10 | 0.1 - 8 |

| Tensile Strength (MPa) | ≥ 800 | ≥ 500 |

| Density (g/cm³) | 4.51 | 10.28 |

| Melting Point (°C) | 1885 | 2620 |

| Electrical Resistivity (Ω·mm²/m) | 0.42 | 0.05 |

|

|

Physical and Chemical Properties:

-

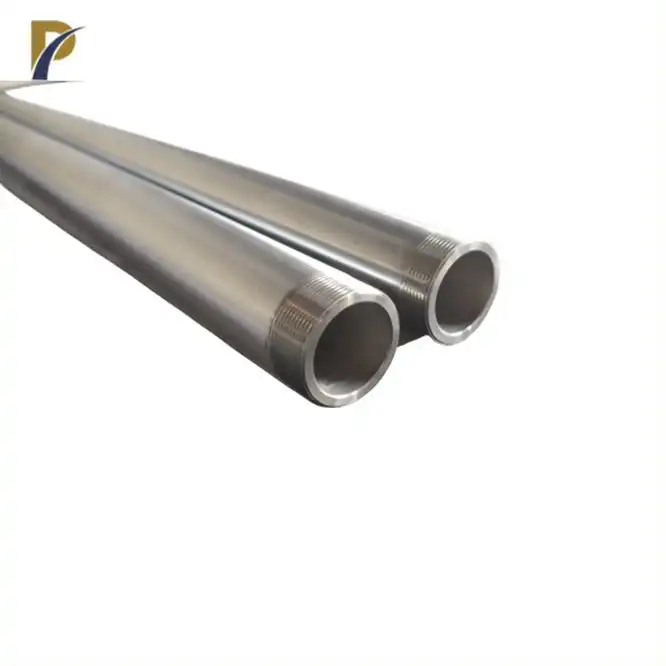

Titanium Wire: Titanium is known for its excellent corrosion resistance, high strength-to-weight ratio, and good biocompatibility. It maintains its properties under high temperatures and is resistant to oxidation and corrosion, making it ideal for aerospace and medical applications.

-

Molybdenum Wire: Molybdenum offers exceptional thermal stability, high melting point, and resistance to wear and corrosion. It is commonly used in high-temperature furnaces and electronic applications due to its strength and durability.

|

|

Product Functions

-

Titanium Wire:

- Corrosion Resistance: Ideal for use in corrosive environments, such as marine and chemical processing.

- Strength and Durability: Suitable for aerospace and medical implants due to its high strength and light weight.

- Biocompatibility: Safe for use in medical devices and implants.

-

Molybdenum Wire:

- High-Temperature Performance: Performs reliably at extremely high temperatures, making it suitable for furnace elements.

- Electrical Conductivity: Used in electronic applications where reliable electrical performance is required.

- Wear Resistance: Ideal for use in applications where abrasion and wear are concerns.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

-

Titanium Wire:

- Aerospace Industry: Used in aircraft components due to its high strength and lightweight properties.

- Medical Devices: Employed in surgical implants and prosthetics due to its biocompatibility.

- Chemical Processing: Applied in reactors and piping systems where corrosion resistance is crucial.

-

Molybdenum Wire:

- High-Temperature Furnaces: Essential in the production of parts that must withstand extreme temperatures.

- Electronics: Utilized in electronic contacts and filaments.

- Lighting: Used in halogen lamps and other high-temperature lighting applications.

|

|

Production Process and Manufacturing

At Shaanxi Peakrise Metal Co., Ltd., we utilize state-of-the-art technology and precision engineering to manufacture our titanium and molybdenum wires. The production process involves:

- Raw Material Selection: High-purity titanium and molybdenum are sourced from reliable suppliers.

- Melting and Refining: Materials are melted and refined to achieve desired purity levels.

- Drawing and Shaping: Wires are drawn to precise diameters and mechanical properties.

- Quality Control: Rigorous testing and inspection ensure that each product meets our quality standards.

Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is a well-established non-ferrous metal production enterprise with extensive experience in manufacturing tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel products. Our facilities are equipped with advanced machinery and technology to ensure the highest quality of our products.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We ensure secure and efficient packaging of our titanium and molybdenum wires to prevent damage during transit. Our logistics team works diligently to deliver products on time, globally.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: Extensive experience in non-ferrous metal production.

- Quality: High-quality products with rigorous quality control.

- Innovation: Use of advanced manufacturing technologies.

- Customer Service: Dedicated support to meet customer needs.

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM services to customize titanium and molybdenum wires according to specific requirements. We work closely with our clients to ensure that their specifications are met.

|

|

Frequently Asked Questions

-

What is the maximum diameter of the wires you offer?

- We offer titanium wires up to 10 mm and molybdenum wires up to 8 mm in diameter.

-

What is the lead time for custom orders?

- Lead times vary depending on the complexity and volume of the order. Typically, it ranges from 4 to 8 weeks.

-

Do you provide samples?

- Yes, we provide samples upon request to evaluate our products before placing larger orders.

Call to Action

Ready to enhance your production with our premium titanium and molybdenum wires? Contact info@peakrisemetal.com Shaanxi Peakrise Metal Co., Ltd. today to discuss your requirements and receive a customized quote. Let us provide you with the quality and service you deserve.