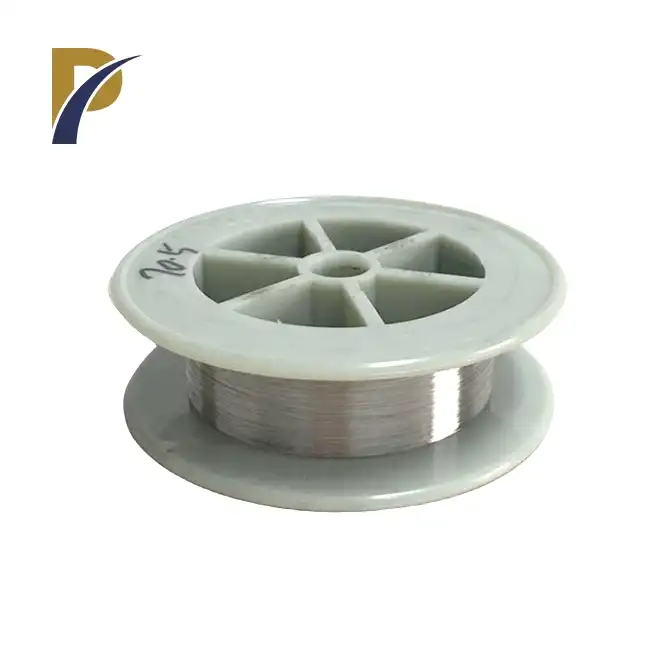

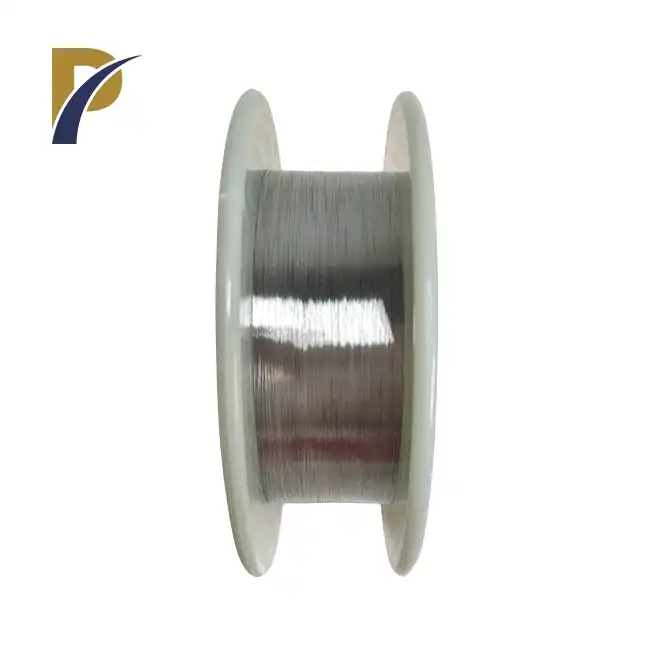

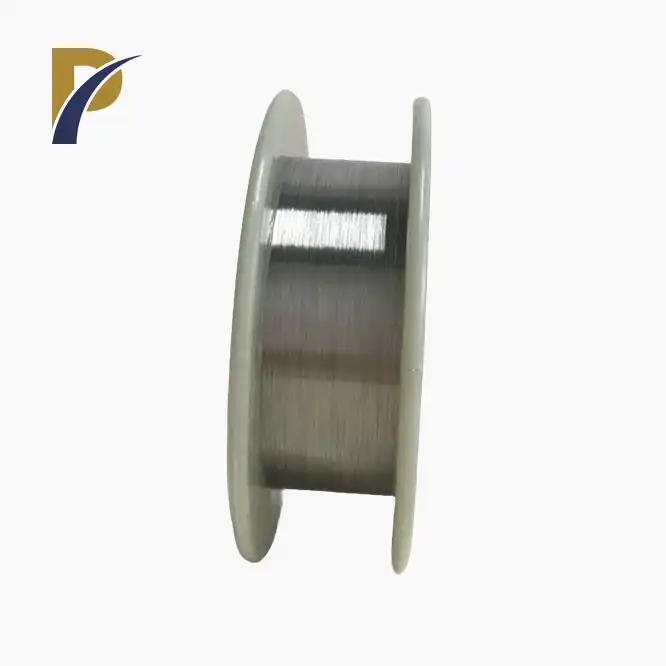

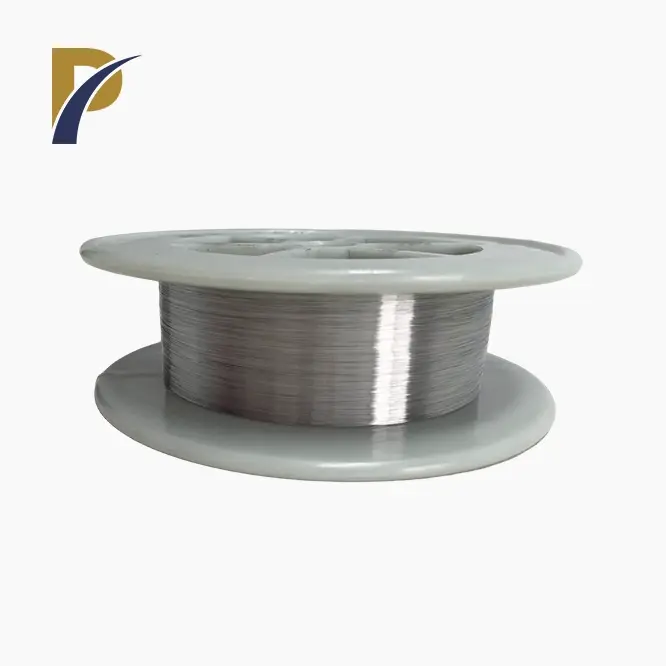

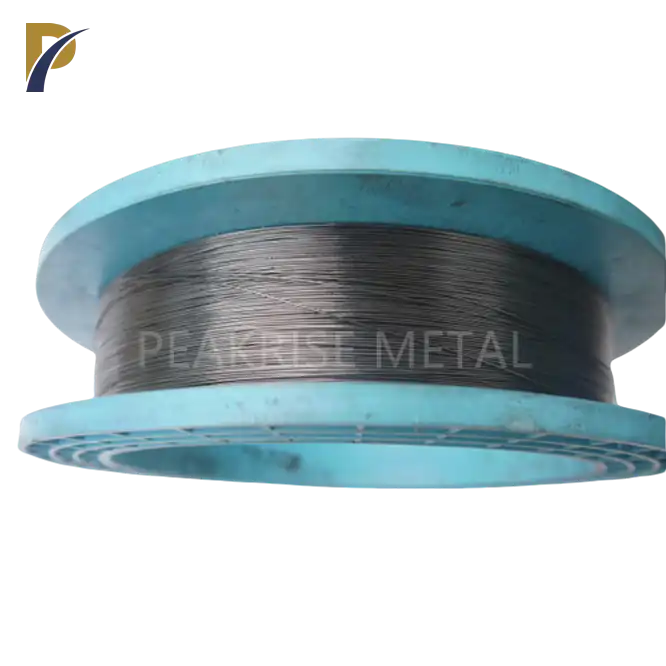

99.95% white color molybdenum wires bright molybdenum wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

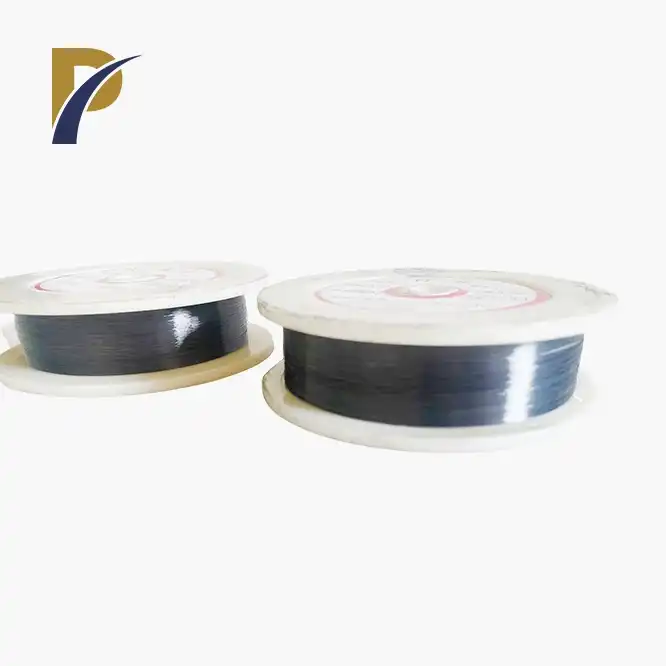

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Sure, I understand your requirements. Here's the content for the product introduction page for Shaanxi Peakrise Metal Co., Ltd.'s bright molybdenum wire:

Product Introduction

Welcome to Shaanxi Peakrise Metal Co., Ltd., your premier supplier of bright molybdenum wire. As a leading manufacturer in the field of non-ferrous and refractory metals, we specialize in producing high-quality bright molybdenum wire tailored to meet the stringent demands of various industries.

bright molybdenum wire are renowned for their exceptional strength and resistance to high temperatures, making them a preferred choice in specialized applications. These wires combine the superior properties of 99.95% pure molybdenum, offering enhanced durability and performance. Our bright molybdenum wire are designed to excel in high-stress environments, providing reliable solutions for advanced technological applications.

At Shaanxi Peakrise Metal Co., Ltd., we leverage our extensive experience and state-of-the-art manufacturing processes to deliver products that meet international standards. Our commitment to quality and innovation ensures that our bright molybdenum wire are suitable for a range of demanding applications, including aerospace, electronics, and industrial processes.

Product Specifications:

| Diameter (mm) | Mo content (%) | Tolerance (mm) | Weight (kg) | Length (m) | Coil diameter(mm) |

| 1.41~1.50 | 99.95 | +0/-0.04 | 4-10 | 250-600 | 450~600 |

| 1.51~1.62 | 99.95 | +0/-0.04 | 4-10 | 220-480 | 450~600 |

| 1.91~2.00 | 99.95 | +0/-0.04 | 5-12 | 170-380 | 450~600 |

| 2.21~2.30 | 99.95 | +0/-0.05 | 5-12 | 130-280 | 450~600 |

| 2.31~2.40 | 99.95 | +0/-0.05 | 6-16 | 130-350 | 600 |

| 3.10~3.18 | 99.95 | +0/-0.05 | 6-16 | 80-200 | 600 |

Physical and Chemical Properties:

- Chemical Composition: Titanium (Ti) 30%, Molybdenum (Mo) 70%

- Melting Point: 3020°C

- Density: 10.2 g/cm³

- Thermal Conductivity: 138 W/m·K

- Electrical Resistivity: 0.12 µΩ·m

|

|

Product Functions:

- High-Temperature Stability: Our titanium molybdenum wires maintain their structural integrity at elevated temperatures, making them ideal for high-temperature applications.

- Corrosion Resistance: These wires exhibit excellent resistance to oxidation and corrosion, ensuring long-term durability in harsh environments.

- Superior Strength: The combination of titanium and molybdenum imparts exceptional tensile strength, enhancing the performance of components made from these wires.

- Electrical Conductivity: They offer good electrical conductivity, which is beneficial for electronic applications where precise electrical performance is required.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Aerospace Industry: Used in aircraft and spacecraft components that require high strength and resistance to extreme temperatures.

- Electronics: Ideal for manufacturing electronic components that operate under high thermal and electrical stress.

- Industrial Processes: Utilized in high-temperature furnaces and reactors where material stability is crucial.

- Medical Devices: Employed in medical instruments and devices that require biocompatibility and strength.

Production Process and Workflow

Our production process for titanium molybdenum wires involves several key steps:

- Raw Material Selection: High-purity titanium and molybdenum are selected and prepared.

- Alloy Preparation: The materials are melted and alloyed to achieve the desired composition.

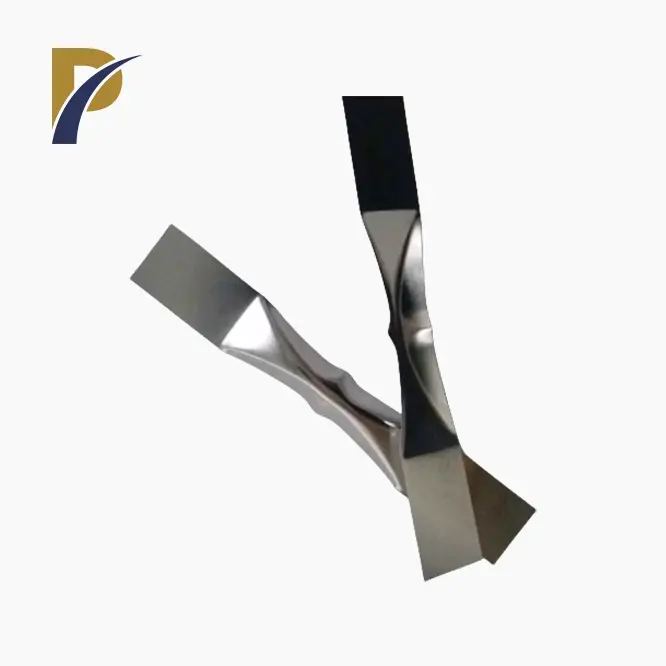

- Wire Drawing: The alloy is drawn into thin wires using advanced drawing techniques.

- Heat Treatment: The wires undergo heat treatment to enhance their mechanical properties.

- Quality Control: Rigorous testing and inspection ensure that the wires meet all specifications and standards.

- Packaging: The finished wires are carefully packaged to prevent damage during transportation.

|

|

|

Company Introduction:

Shaanxi Peakrise Metal Co., Ltd. is a leading enterprise in the production of non-ferrous and refractory metals. Our extensive product range includes tungsten-copper alloys, molybdenum-copper alloys, and various other high-performance materials. With a wealth of experience and a commitment to innovation, we are dedicated to providing top-quality products that meet the highest industry standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

Our titanium molybdenum wires are packaged in durable, protective materials to ensure safe delivery. We offer flexible logistics solutions to accommodate global shipping needs, ensuring that your order arrives on time and in excellent condition.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Experience: Over [X] years of experience in producing high-quality refractory metals.

- Quality Assurance: Strict quality control measures to ensure product reliability.

- Customer-Centric: Tailored solutions and exceptional customer service.

- Innovation: Ongoing research and development to advance our product offerings.

- Global Reach: Reliable shipping and support for international clients.

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers customized processing services to meet your specific requirements. Whether you need bespoke wire diameters or special packaging, our team is equipped to provide tailored solutions that fit your needs.

|

|

Frequently Asked Questions (FAQs)

-

What is the maximum length of the titanium molybdenum wires you can supply?

- We can supply wires up to 2000 meters in length.

-

What are the standard diameters available?

- Diameters range from 0.1 mm to 3.0 mm.

-

Do you offer custom sizes?

- Yes, we provide OEM services for customized sizes and specifications.

-

What is the typical lead time for orders?

- Lead times vary depending on the order size and customization. Please contact us for specific details.

Call to Action (CTA)

Ready to enhance your projects with high-quality bright molybdenum wires? Contact Shaanxi Peakrise Metal Co., Ltd. today for a quote or to learn more about our products and services. Our expert team is here to assist you with all your needs.

Contact Us: info@peakrisemetal.com

Phone: 0086-13186382597

Let me know if you need any adjustments or additional information!