tungsten molybdenum wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

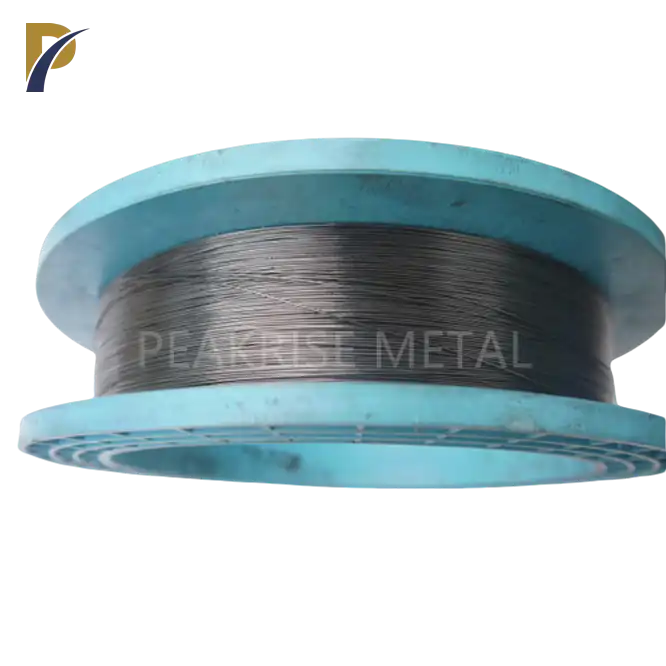

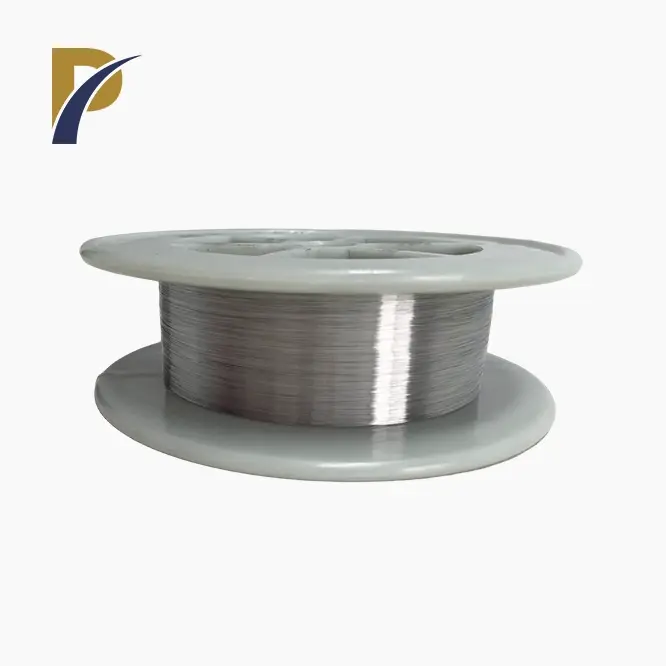

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Product Introduction

Tungsten Molybdenum Wire, produced by Shaanxi Peakrise Metal Co., Ltd., stands at the forefront of advanced materials in the global market. Our company is a leading manufacturer specializing in tungsten, molybdenum, and other high-performance non-ferrous metals. Our tungsten molybdenum wire is engineered to meet the highest standards of quality and performance, catering to diverse industrial applications that demand exceptional material properties.

Tungsten molybdenum wire combines the strengths of both tungsten and molybdenum, offering superior resistance to high temperatures, corrosion, and wear. This makes it an ideal choice for applications in the aerospace, electronics, and industrial sectors. At Shaanxi Peakrise Metal Co., Ltd., we leverage our extensive experience and cutting-edge technology to deliver products that enhance operational efficiency and reliability.

|

|

Product Parameters

| Parameter | Tungsten Wire | Molybdenum Wire | Tungsten Molybdenum Wire |

|---|---|---|---|

| Diameter (mm) | 0.1 - 5.0 | 0.1 - 5.0 | 0.1 - 5.0 |

| Length (m) | Customizable | Customizable | Customizable |

| Purity (%) | >99.95 | >99.95 | >99.95 |

| Tensile Strength (MPa) | 500 - 800 | 300 - 600 | 600 - 900 |

| Melting Point (°C) | 3422 | 2620 | 3000 |

| Density (g/cm³) | 19.25 | 10.28 | 18.25 |

Physical and Chemical Properties

- Density: Tungsten molybdenum wire exhibits high density, contributing to its excellent thermal and electrical conductivity.

- Melting Point: With a melting point approaching 3000°C, it can withstand extreme temperatures without degrading.

- Thermal Expansion: Low thermal expansion coefficient ensures stability and precision in high-temperature applications.

- Corrosion Resistance: It provides exceptional resistance to oxidation and corrosion, ensuring longevity and reliability.

|

|

Product Functions

- High Temperature Resistance: The tungsten molybdenum wire maintains its structural integrity at temperatures exceeding 2000°C, making it suitable for high-temperature environments.

- Thermal Conductivity: Superior thermal conductivity enhances heat dissipation in electronic components, preventing overheating.

- Electrical Conductivity: Provides excellent electrical conductivity for use in precision electronic applications.

- Strength and Durability: High tensile strength ensures durability and resistance to wear and tear, extending the lifespan of components.

|

High Melting PointMolybdenum electrodes have an extremely high melting point (2623°C), maintaining stability in high-temperature environments. |

Excellent ConductivityMolybdenum electrodes offer exceptional electrical conductivity, ensuring stable and efficient current transmission under high current conditions. |

Corrosion ResistanceMolybdenum resists oxidation and chemical corrosion, making it suitable for glass melting and high-temperature metal processing. |

High Thermal ConductivityMolybdenum electrodes have high thermal conductivity, allowing rapid heat dissipation, preventing overheating, and increasing efficiency and lifespan. |

Product Applications

- Aerospace: Used in aerospace applications where high temperature and wear resistance are critical.

- Electronics: Ideal for electronic devices that require reliable and efficient heat dissipation.

- Lighting: Employed in lighting systems, particularly in high-intensity discharge lamps.

- Industrial Manufacturing: Utilized in manufacturing processes that involve high temperatures and corrosive environments.

|

|

Production Process and Manufacturing

At Shaanxi Peakrise Metal Co., Ltd., we follow a rigorous manufacturing process to produce tungsten molybdenum wire. Our process includes:

- Raw Material Selection: High-purity tungsten and molybdenum ores are selected and processed.

- Powder Preparation: The ores are converted into fine powders through a series of chemical and mechanical processes.

- Wire Drawing: The powders are sintered and drawn into wire form using advanced drawing technology.

- Quality Testing: Each batch undergoes thorough testing to ensure compliance with stringent quality standards.

- Finishing: The wire is treated and finished to meet specific customer requirements and application standards.

|

|

|

About Us

Shaanxi Peakrise Metal Co., Ltd. is a renowned producer of non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. With a rich history and extensive experience in the industry, we offer a comprehensive range of products including tungsten-copper alloy and molybdenum-copper alloy. Our commitment to quality and innovation sets us apart in the global market.

Logistics and Packaging

Our tungsten molybdenum wire is meticulously packaged to ensure it arrives in optimal condition. We offer various packaging solutions, including custom packaging to meet specific customer requirements. Our logistics team ensures timely and secure delivery to clients worldwide.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: Decades of experience in non-ferrous metal production.

- Quality: Commitment to the highest standards of material quality and performance.

- Innovation: Continuous investment in technology and processes.

- Customer Service: Dedicated support to address all client needs and queries.

- Global Reach: Efficient logistics network ensuring timely delivery.

|

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM services for tungsten molybdenum wire, allowing customers to customize products according to their specific needs. Our team works closely with clients to ensure their exact specifications are met.

|

|

Frequently Asked Questions

-

What is the maximum temperature tolerance of tungsten molybdenum wire?

- Tungsten molybdenum wire can tolerate temperatures up to 3000°C.

-

Can you provide custom lengths and diameters for the wire?

- Yes, we offer customizable lengths and diameters to meet specific requirements.

-

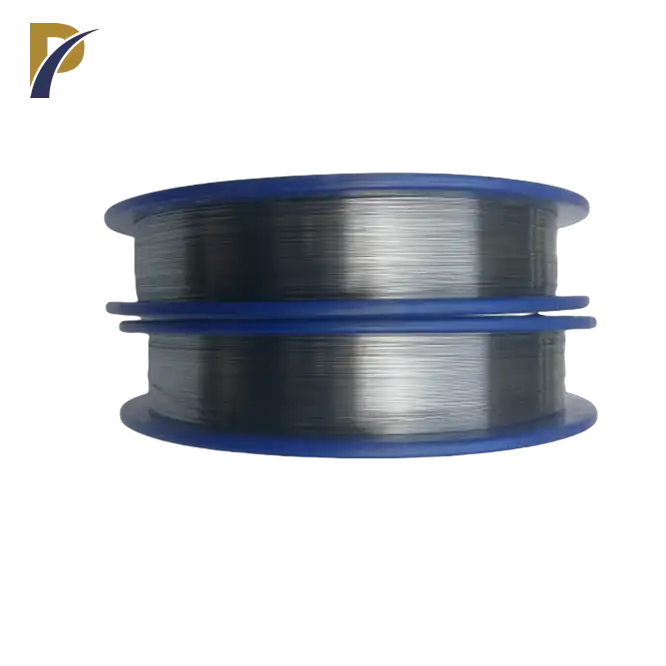

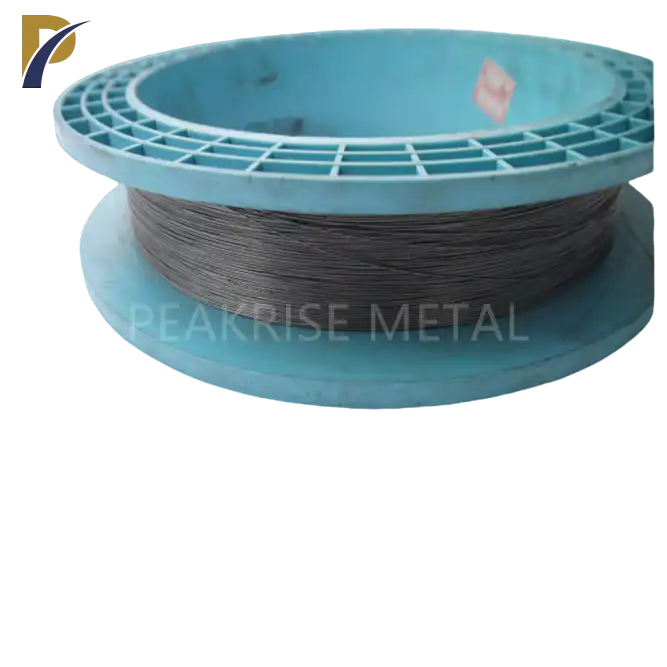

What are the standard packaging options for the wire?

- Our standard packaging includes spools and coils, but custom packaging options are available.

-

Do you offer technical support for installation and use?

- Yes, our technical team provides comprehensive support and guidance.

Contact Us:For more information about our high-quality tungsten molybdenum wire or to place an order, please get in touch with us at info@peakrisemetal.com. Our team of experts is ready to assist you with all your requirements and provide the best solutions for your high-temperature applications. Partner with Shaanxi Peakrise Metal Co., Ltd. today and experience the difference in quality and service.

YOU MAY LIKE

-

VIEW MOREmolybdenum wire drawing

VIEW MOREmolybdenum wire drawing -

VIEW MOREmolybdenum wires

VIEW MOREmolybdenum wires -

VIEW MOREmolybdenum heater wire

VIEW MOREmolybdenum heater wire -

VIEW MORE99.95% white color molybdenum wires bright molybdenum wire

VIEW MORE99.95% white color molybdenum wires bright molybdenum wire -

VIEW MOREmolybdenum wire for wire winding core wire hanger molybdenum lead wire

VIEW MOREmolybdenum wire for wire winding core wire hanger molybdenum lead wire -

VIEW MORE8mm tungsten rod

VIEW MORE8mm tungsten rod -

VIEW MOREmosi2 heating elements price

VIEW MOREmosi2 heating elements price -

VIEW MOREpure tungsten wire

VIEW MOREpure tungsten wire