tungsten and molybdenum alloy

W Content: 50% (wt%)

Mo Content: 50% (wt%)

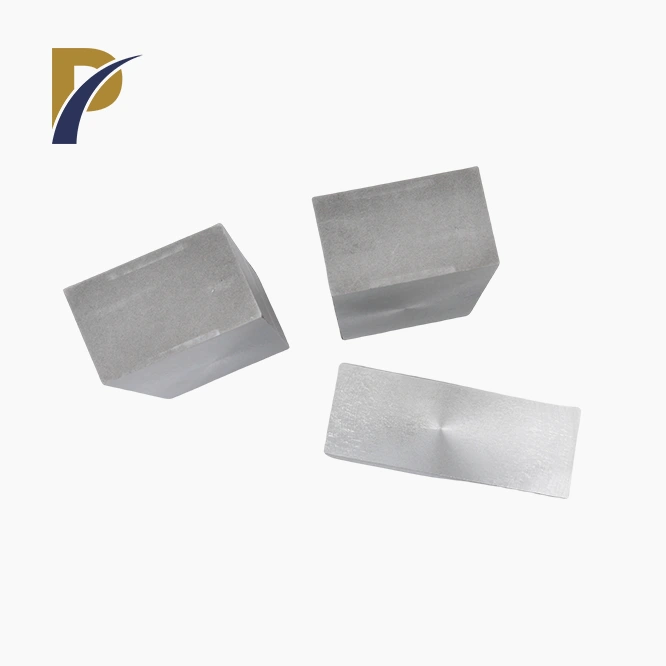

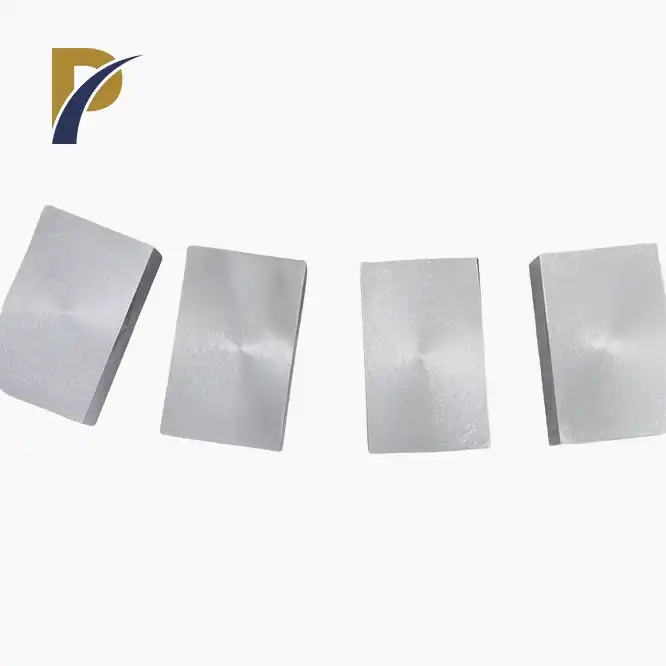

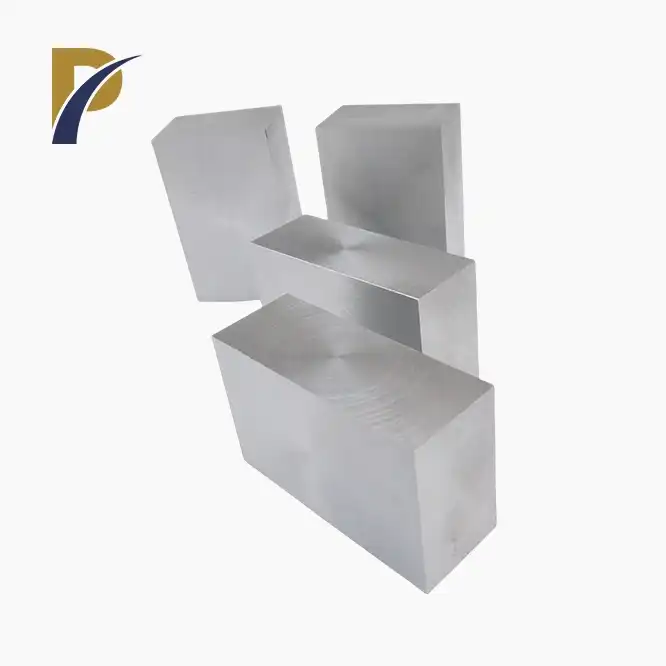

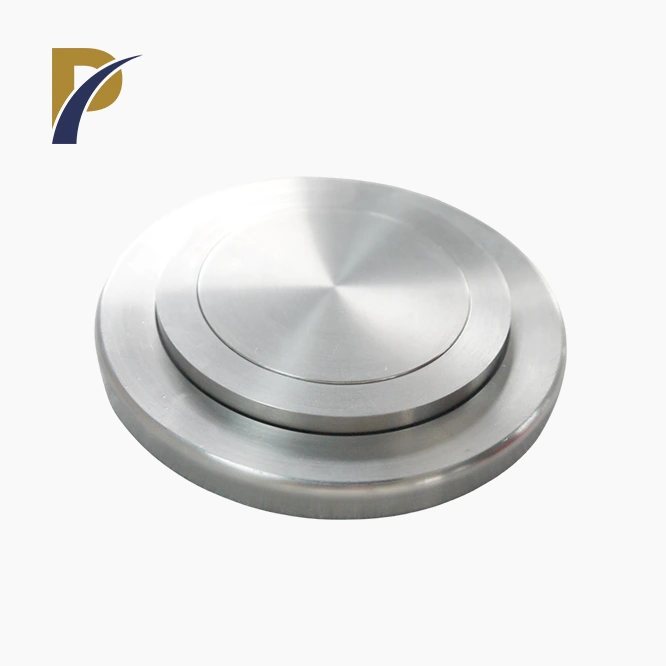

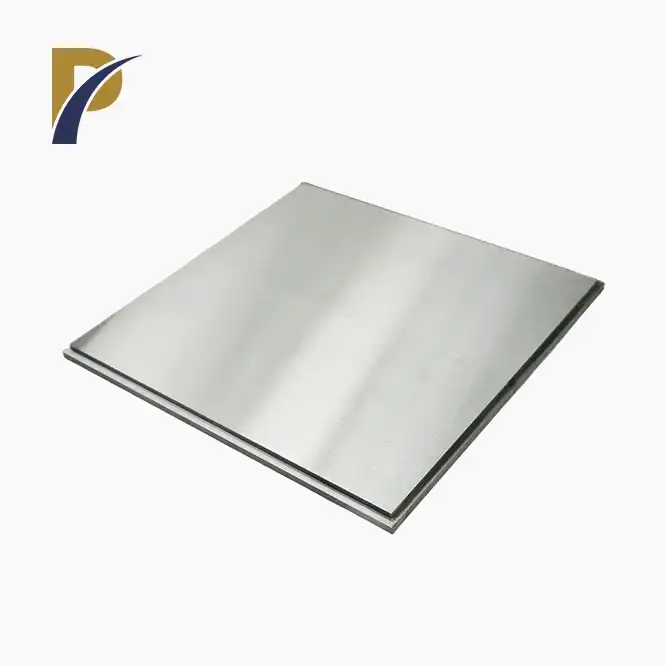

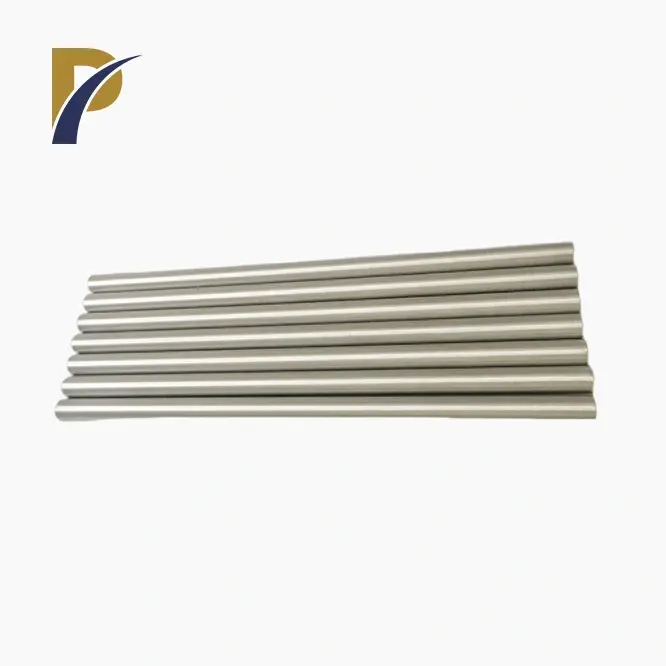

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction

Tungsten and molybdenum alloys are integral materials in industries requiring high-temperature resistance, strength, and durability. These alloys have gained recognition for their unique properties, which include excellent thermal and electrical conductivity, low thermal expansion, and outstanding corrosion resistance. As a professional supplier, Shaanxi Peakrise Metal Co., Ltd. provides high-quality tungsten and molybdenum alloys for industries such as aerospace, electronics, chemical processing, and defense. With a global reputation for excellence, our products are specifically engineered to meet the rigorous demands of modern manufacturing and innovation.

At Shaanxi Peakrise Metal Co., Ltd., we understand the critical role tungsten and molybdenum alloys play in high-performance applications. We have invested heavily in advanced manufacturing technology and research, ensuring that our alloys meet international standards for quality, precision, and performance. Our comprehensive selection of tungsten and molybdenum alloys is designed to provide solutions for various industrial challenges, including heat resistance, wear protection, and enhanced conductivity. With over a decade of experience, we have become a trusted partner for customers worldwide, offering customized solutions to meet the specific needs of each project.

Product Parameters

| Parameter | Tungsten Alloy (WMo) | Molybdenum Alloy (MoW) |

|---|---|---|

| Density (g/cm³) | 19.3 | 10.28 |

| Melting Point (°C) | 3,422 | 2,620 |

| Tensile Strength (MPa) | 980 | 700 |

| Electrical Conductivity | 31% IACS | 34% IACS |

| Thermal Conductivity (W/mK) | 170 | 138 |

| Parameter | Tungsten-Copper Alloy | Molybdenum-Copper Alloy |

|---|---|---|

| Density (g/cm³) | 16.75 | 9.90 |

| Electrical Resistivity (µΩ·cm) | 3.2 | 4.1 |

| Thermal Expansion (µm/mK) | 6.4 | 7.8 |

| Hardness (HB) | 320 | 290 |

| Young's Modulus (GPa) | 360 | 330 |

| Parameter | High-Strength Tungsten Alloy | Tantalum Alloy |

|---|---|---|

| Density (g/cm³) | 18.5 | 16.6 |

| Melting Point (°C) | 3,390 | 3,017 |

| Thermal Conductivity (W/mK) | 160 | 57 |

| Tensile Strength (MPa) | 1,050 | 800 |

| Electrical Resistivity (µΩ·cm) | 5.6 | 13.1 |

|

|

|

Physical and Mechanical Properties

Tungsten and molybdenum alloys offer outstanding mechanical properties that make them suitable for demanding applications. These alloys are known for their high melting points, making them ideal for extreme environments. Tungsten alloys, in particular, have densities close to gold, which provides excellent radiation shielding capabilities. Molybdenum alloys, on the other hand, are lighter and offer better electrical conductivity, making them useful in electronics and heat-resistant applications.

Product Functions

- Heat Resistance: Both tungsten and molybdenum alloys can withstand extreme temperatures without losing their mechanical integrity. This makes them essential in furnace components, aerospace, and defense industries.

- Electrical Conductivity: These alloys offer excellent electrical conductivity, making them suitable for use in electrical contacts, circuit components, and other high-precision electronic devices.

- Corrosion Resistance: Tungsten and molybdenum alloys resist oxidation and corrosion even at elevated temperatures, providing long-lasting performance in aggressive environments such as chemical processing plants.

- Radiation Shielding: Tungsten alloys are dense and have excellent radiation absorption properties, making them suitable for medical equipment, nuclear reactors, and defense shielding applications.

- Wear Resistance: The high hardness and durability of these alloys provide superior wear resistance, extending the life of tools, molds, and other high-stress components.

Precision-Engineered Molybdenum-Tungsten Alloy Tailored to Your Needs!

At Peakrise Metal, your requirements take top priority. With over a decade of expertise, we transform complex ideas into practical solutions through our precision-engineered molybdenum tungsten alloy. From initial design to detailed specification adjustments, every step of our manufacturing process is customized to meet your exact demands.

Customization Options for Molybdenum Tungsten Alloy:

Size and Shape: Adjust the length, width, and overall design to match specific applications, ensuring seamless compatibility with various equipment and working conditions.

Purity: Choose from different molybdenum tungsten purity levels to achieve optimal performance in specialized applications.

Coating Treatment: Improve durability with tailored coatings, such as anti-oxidation or conductive layers, suited to specific environments.

Connection Design: Select customized connection methods, including welded joints or bolted structures, for secure and efficient installation.

Packaging: Opt for tailored packaging solutions that ensure safe transport and storage while maintaining product integrity.

Why choose molybdenum-tungsten alloy from Peakrise Metal?

At Peakrise Metal, we uphold industry-leading standards by integrating advanced techniques, innovative technology, and extensive expertise. Our dedication ensures that your specific needs are met with premium molybdenum tungsten alloy solutions.

Expertise and Experience: With over a decade in the industry, we combine cutting-edge technology with deep expertise to deliver top-tier molybdenum tungsten alloy tailored to your exact specifications.

Custom Solutions: We provide fully customized solutions, including unique sizes, shapes, and coatings, to meet precise performance requirements.

Unmatched Quality: Committed to superior manufacturing, we guarantee each molybdenum tungsten alloy product delivers exceptional performance, longevity, and reliability—ensuring excellent value for your investment

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Product Applications

-

Aerospace Industry: Tungsten and molybdenum alloys are widely used in aerospace due to their high-temperature stability and low thermal expansion. They are used in rocket nozzles, heat shields, and other high-performance components.

-

Electronics and Semiconductors: Due to their excellent electrical and thermal conductivity, these alloys are indispensable in the manufacture of semiconductors, electronic circuits, and high-frequency devices.

-

Medical Devices: Tungsten alloys are often used for radiation shielding in medical devices such as X-ray machines and radiation therapy equipment.

-

Chemical Processing: Molybdenum alloys resist corrosion and are used in high-temperature chemical reactors, vessels, and pipes.

-

Defense Industry: Tungsten's high density and radiation shielding properties make it ideal for military applications, including armor-piercing projectiles and defense shielding.

Product Process and Production Flow

Shaanxi Peakrise Metal Co., Ltd. employs state-of-the-art manufacturing processes to ensure the highest quality tungsten and molybdenum alloy products. Our production flow includes:

- Raw material selection: High-purity tungsten and molybdenum materials are sourced to meet precise alloy specifications.

- Sintering: Using intermediate frequency sintering furnaces for the consolidation of tungsten and molybdenum powders.

- Vacuum arc melting: Ensures the homogeneity and quality of alloys by melting in a controlled vacuum environment.

- Rolling and drawing: Precision rolling and wire drawing processes ensure accurate dimensions and mechanical properties.

- Heat treatment: Vacuum annealing furnaces are used to achieve the desired material properties, including improved ductility and toughness.

- Final inspection: Comprehensive product testing is conducted to ensure compliance with industry standards and customer requirements.

|

|

|

|

Logistics and Packaging

- Wooden Packaging: For larger, heavier products to ensure maximum protection during transport.

- Carton Packaging: Lightweight and standard products are packed securely in cartons.

- Foam-Filled Packaging: For fragile components that require extra cushioning.

- Waterproof and Moisture-Proof Packaging: To prevent product damage during transport in humid environments.

- Customized Packaging: Tailored to the specific needs of each client, ensuring products arrive in perfect condition.

- International Standard Packaging: All packaging meets international standards for export and logistics.

|

|

|

|

|

|

|

|

Why Choose Us?

-

Rich Experience: With over a decade in the industry, Shaanxi Peakrise Metal Co., Ltd. has built a reputation for delivering high-quality tungsten and molybdenum alloys globally.

-

Comprehensive Services: We provide a full range of services, from material sourcing to final product testing, ensuring every order meets exact specifications.

-

Advanced Technology: Our state-of-the-art equipment and facilities enable us to produce highly accurate and consistent alloy products.

-

Customization Options: We offer OEM/ODM services to meet the unique needs of each customer, providing flexible production capabilities.

-

Global Reach: Our products are exported to over 20 countries, with long-term relationships built on trust, quality, and reliability.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. specializes in custom tungsten and molybdenum alloy products. We support OEM/ODM services, allowing clients to request specific product designs, dimensions, and material compositions. Our experienced R&D team works closely with clients to develop tailored solutions that meet their exact requirements.

|

|

FAQ

-

What are the lead times for tungsten and molybdenum alloy orders?

- Lead times vary depending on the order size and product complexity, but standard orders are usually delivered within 2-4 weeks.

-

Can I request custom sizes or compositions?

- Yes, we offer customized solutions through our OEM/ODM services.

-

How do you ensure product quality?

- We adhere to strict ISO 9001 quality control standards and conduct comprehensive testing on all products before shipping.

-

What are the shipping options?

- We offer sea, air, land, multimodal transport, and courier services depending on customer preferences.

-

Do you provide samples?

- Yes, we provide free samples for testing and evaluation upon request.

Contact Us

For more information about our tungsten and molybdenum alloy products or to place an order, please contact Shaanxi Peakrise Metal Co., Ltd. at info@peakrisemetal.com. We look forward to working with you to provide high-quality, custom solutions for your industry needs.