Zirconium Alloy Seamless Tubes

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Alloy Seamless Tubes by Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Zirconium Alloy Seamless Tubes are critical components in industries requiring high-performance materials that exhibit excellent corrosion resistance, heat resistance, and mechanical properties. Zirconium alloys, particularly Zr702 and Zr705, are widely used due to their remarkable strength-to-weight ratio and outstanding resistance to both acidic and basic environments, which makes them ideal for applications in chemical processing, nuclear energy, and aerospace engineering.

Shaanxi Peakrise Metal Co., Ltd. is a trusted global supplier of Zirconium Alloy Seamless Tubes. With years of expertise in non-ferrous metals, we manufacture high-quality tubes tailored to meet the rigorous standards of diverse industries. Our seamless tubes are crafted with precision and advanced technology, ensuring durability, optimal performance, and reliability in the most demanding conditions. Our dedication to producing premium quality materials makes us the preferred supplier for customers across various industries worldwide. Whether you're looking for Zirconium Alloy Seamless Tubes for a high-temperature chemical process or a reliable solution for a nuclear power plant, Shaanxi Peakrise Metal is committed to providing the best products and services to meet your specific needs.

|

|

Product Specifications

Below are the standard specifications for our Zirconium Alloy Seamless Tubes. We provide customized options to meet specific requirements.

| Parameter | Zirconium Alloy 702 | Zirconium Alloy 705 | Other Zirconium Alloys |

|---|---|---|---|

| Composition (Zr content) | 99.2% | 97.5% | Varies by request |

| Outer Diameter Range (mm) | 6 - 130 | 6 - 130 | Customizable |

| Wall Thickness (mm) | 0.5 - 15 | 0.5 - 15 | Customizable |

| Tensile Strength (MPa) | 379 | 620 | Varies by grade |

| Yield Strength (MPa) | 207 | 480 | Varies by grade |

| Elongation (%) | 16% | 20% | Varies by grade |

| Max Operating Temperature (°C) | 400 | 550 | Varies by alloy |

Physical and Chemical Properties

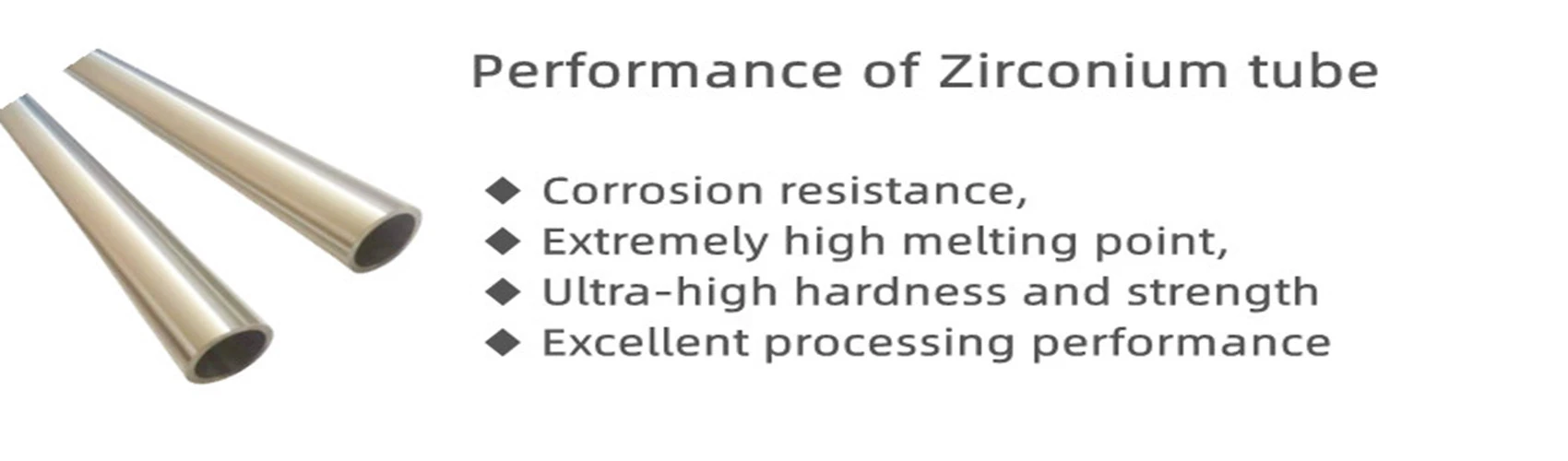

Zirconium alloys are highly prized for their corrosion resistance, particularly in environments where both acids and bases are present. Their properties also include:

- Density: 6.49 g/cm³

- Melting Point: 1855°C

- Thermal Conductivity: 22 W/m·K

- Electrical Resistivity: 40 μΩ·cm

- Modulus of Elasticity: 99 GPa

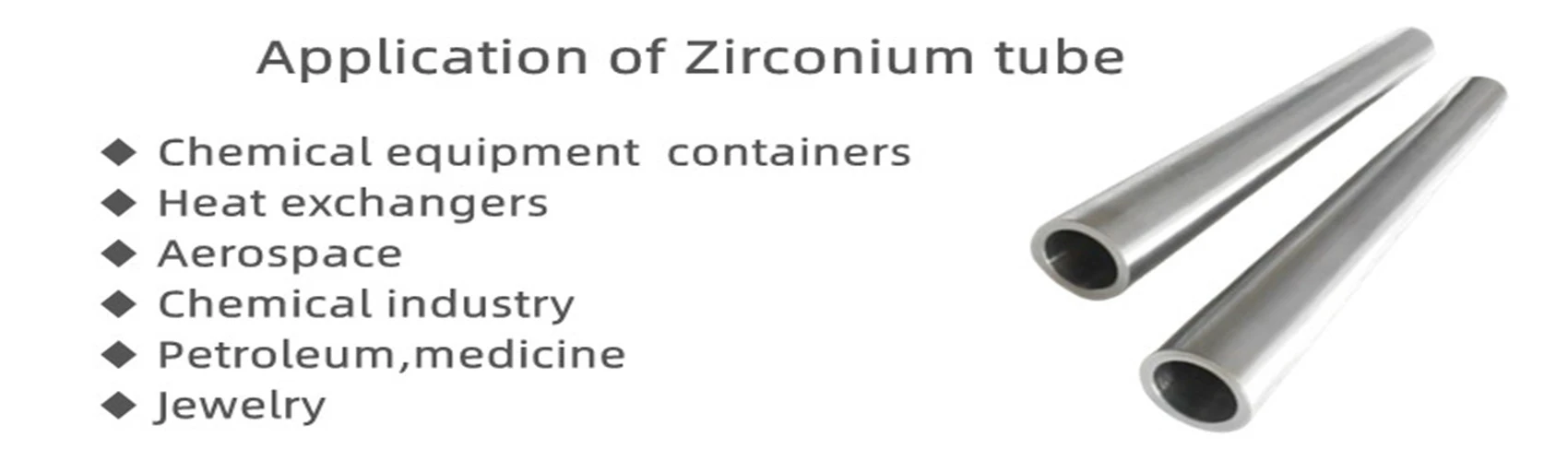

Product Applications

- Nuclear Industry: Zirconium Alloy Seamless Tubes are primarily used in nuclear reactors due to their low neutron absorption cross-section, making them ideal for fuel cladding and structural components in reactors.

- Chemical Processing: Their resistance to corrosion by acids and bases makes them perfect for use in chemical plants, particularly in corrosive environments where stainless steel might fail.

- Aerospace: Lightweight and strong, Zirconium Alloy Seamless Tubes are used in aerospace applications for their ability to withstand extreme temperatures and pressures without deformation.

- Medical: Due to their biocompatibility, Zirconium Alloy Seamless Tubes are also used in the medical industry for applications such as surgical implants and prosthetics.

Production Process & Manufacturing Flow

Our Zirconium Alloy Seamless Tubes are manufactured using advanced techniques to ensure the highest level of precision and quality. The process includes:

- Melting and Alloying: High-purity zirconium is melted in a vacuum arc melting furnace to create the desired alloy composition.

- Extrusion and Rolling: The zirconium alloy is extruded and rolled to achieve the required dimensions and mechanical properties.

- Heat Treatment: Tubes undergo annealing in a vacuum annealing furnace to improve ductility and reduce internal stresses.

- Cold Drawing: The tubes are cold-drawn to achieve a seamless structure with precise tolerances.

- Testing: Rigorous testing is conducted at every stage, including ultrasonic testing, eddy current testing, and mechanical property testing, to ensure compliance with international standards.

Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. has been a leading producer of non-ferrous metal products since 2010. Our factory is equipped with state-of-the-art equipment, including vacuum arc melting furnaces, intermediate frequency sintering furnaces, CNC machines, and more. We have the capacity to meet large orders while maintaining strict quality control measures, ensuring that every product meets the highest standards. Our products are exported globally, and we have built long-term partnerships with clients in various industries.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging & Logistics

To ensure safe transportation, we offer the following packaging solutions:

- Wooden Crates: Durable, custom-built crates that meet international shipping standards.

- Carton Packaging: For smaller orders, we use reinforced cartons for added protection.

- Foam Inserts: To prevent movement and damage, foam inserts are used inside packaging.

- Waterproof and Moisture-Proof: Tubes are wrapped in waterproof materials to protect them from moisture during transit.

- Custom Packaging: Available based on customer requirements.

|

|

|

|

|

|

|

|

|

|

Our logistics services include:

- Sea Freight: Cost-effective for large orders and international shipping.

- Air Freight: Fast delivery for urgent orders.

- Land Freight: For orders within a continent or country.

- Multimodal Transport: A combination of sea, air, and land transport to reduce costs and optimize delivery times.

- Courier Services: For small, time-sensitive deliveries.

Why Choose Us?

- Experienced Manufacturer: Over a decade of experience in producing non-ferrous metal products.

- Global Reach: We export to over 20 countries, including the USA, Germany, South Korea, and Australia.

- Quality Assurance: Every batch undergoes stringent testing to meet international standards.

- Advanced Equipment: Equipped with cutting-edge manufacturing technology to ensure precision and quality.

- Custom Solutions: We offer OEM/ODM services to meet specific customer requirements.

- Excellent Customer Service: Our team is dedicated to providing timely and effective communication.

-

What are the main alloys used in Zirconium Alloy Seamless Tubes?

We primarily offer Zr702 and Zr705 alloys, but we can produce tubes in other zirconium alloys upon request. -

What is the maximum operating temperature for Zirconium Alloy Seamless Tubes?

Zr705 tubes can operate at temperatures up to 550°C, while Zr702 is rated for up to 400°C. -

Do you provide certificates of compliance?

Yes, we provide certificates that confirm our tubes meet international standards such as ASTM and ISO. -

What is the lead time for an order?

Typical lead time is 4-6 weeks, but we can expedite orders for urgent requests. -

Can you handle large volume orders?

Yes, our factory has the capacity to handle bulk orders without compromising on quality.

Call to Action: Contact Us

Are you looking for high-quality Zirconium Alloy Seamless Tubes? Shaanxi Peakrise Metal Co., Ltd. is ready to fulfill your needs. Whether you have a standard order or need a custom solution, we can help. Contact us today at info@peakrisemetal.com to discuss your project requirements and receive a competitive quote. Let's work together to bring your ideas to life with premium zirconium alloy solutions!

YOU MAY LIKE

-

VIEW MOREtungsten heating wire

VIEW MOREtungsten heating wire -

VIEW MOREwelding tungsten boat

VIEW MOREwelding tungsten boat -

VIEW MOREtantalum seamless pipe tube

VIEW MOREtantalum seamless pipe tube -

VIEW MOREtungsten tantalum alloy plate

VIEW MOREtungsten tantalum alloy plate -

VIEW MOREnickel crucible 100ml

VIEW MOREnickel crucible 100ml -

VIEW MOREsic heating elements

VIEW MOREsic heating elements -

VIEW MOREZr 702 cylindrical zirconium crucible

VIEW MOREZr 702 cylindrical zirconium crucible -

VIEW MORE50ml 1mm thickness pure zirconium crucible

VIEW MORE50ml 1mm thickness pure zirconium crucible