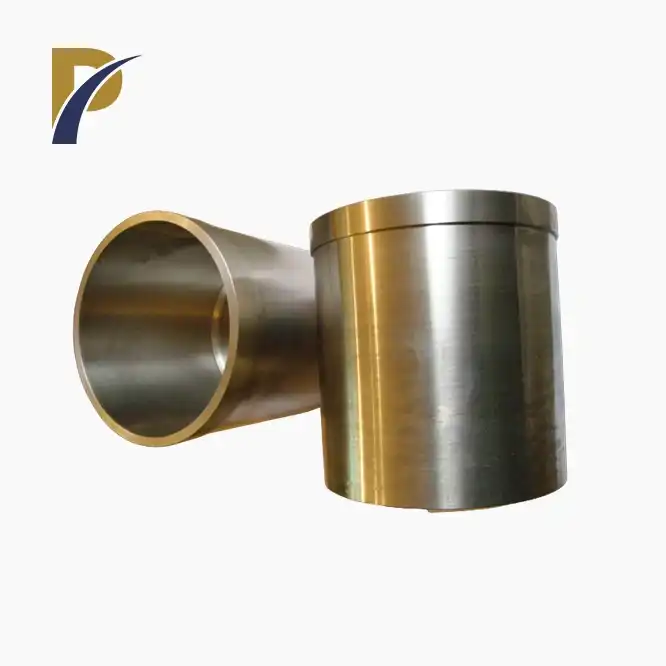

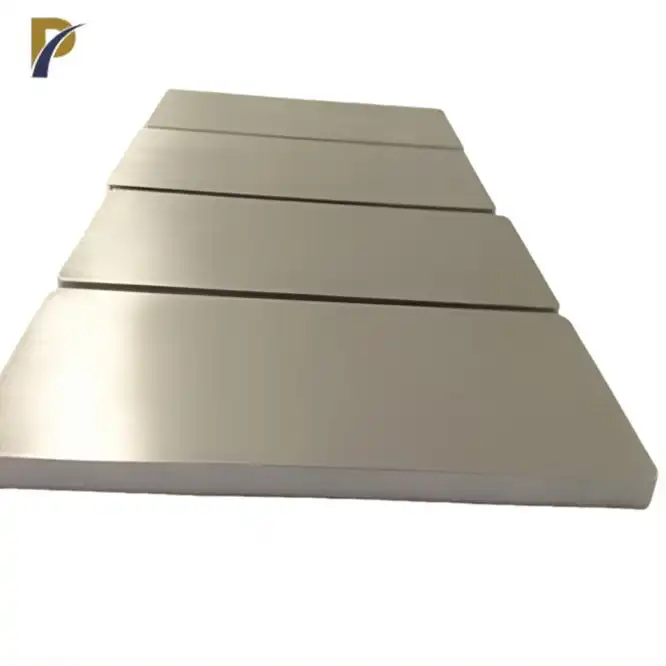

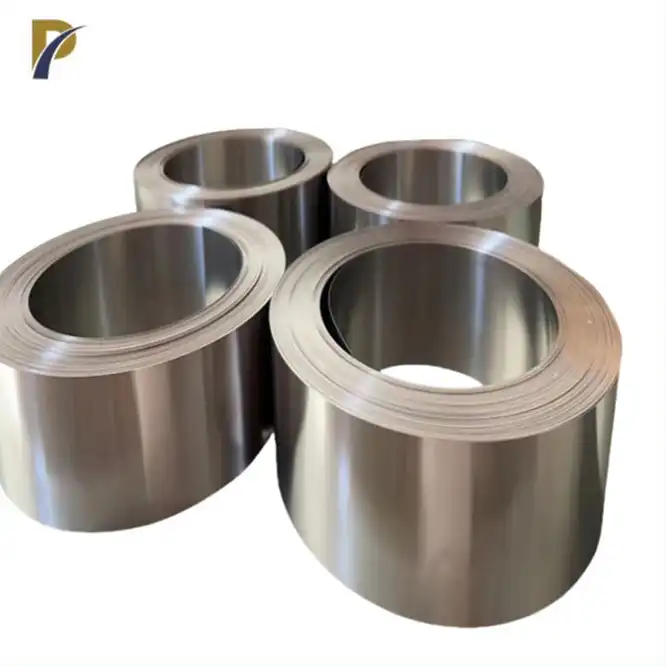

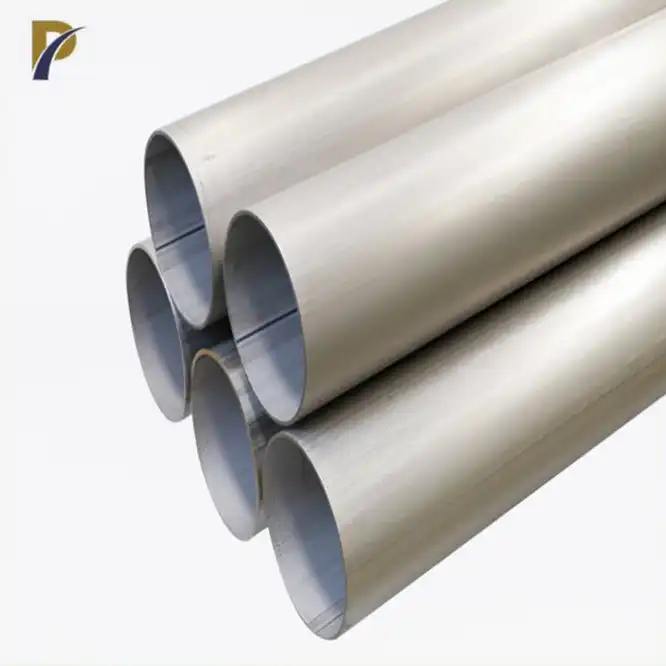

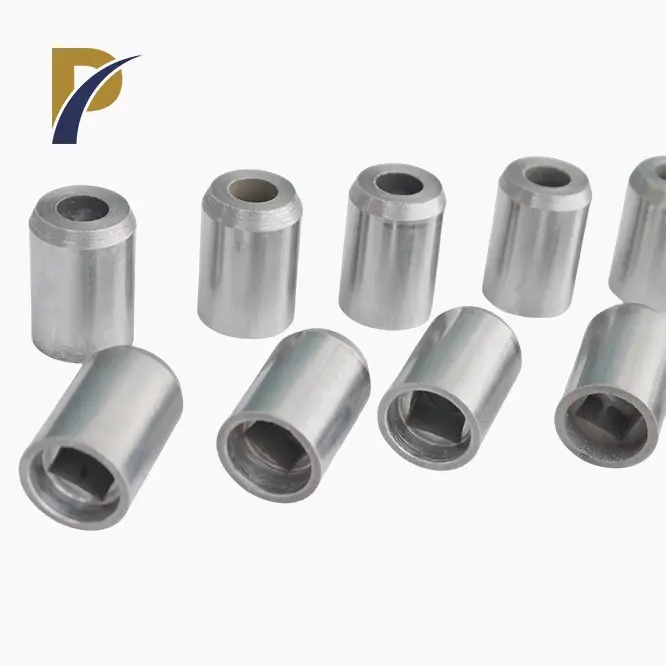

High-Quality Zirconium Components

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

High-Quality Zirconium Components by Shaanxi Peakrise Metal Co., Ltd.

Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of high-quality zirconium components to various global industries. With over a decade of experience in the production and export of non-ferrous metals, we specialize in providing precision-engineered zirconium products that meet the rigorous demands of industries such as aerospace, medical, chemical, and nuclear power. Our zirconium components are known for their exceptional resistance to corrosion, high-temperature stability, and superior mechanical properties. As a reliable partner, Shaanxi Peakrise Metal Co., Ltd. is committed to delivering high-performance zirconium components that meet the highest industry standards and customer specifications.

Zirconium is a key material in several high-tech applications, valued for its ability to withstand harsh environments without degrading. Its low neutron-capture cross-section makes it indispensable in nuclear reactors, while its corrosion resistance is critical in chemical processing industries. At Shaanxi Peakrise Metal, we ensure that every zirconium component we produce adheres to the strictest quality controls, making us a trusted partner for companies requiring high-precision, durable materials. We combine advanced production technology with extensive industry expertise to offer custom solutions that meet your specific requirements.

Product Specifications

| Property | Value | Unit |

|---|---|---|

| Purity | ≥ 99.2% | - |

| Melting Point | 1855 | °C |

| Density | 6.52 | g/cm³ |

| Thermal Conductivity | 22.7 | W/m·K |

| Elastic Modulus | 94 | GPa |

| Tensile Strength | 230-260 | MPa |

| Mechanical Properties | Zirconium Alloy Zr702 | Zirconium Alloy Zr705 |

|---|---|---|

| Tensile Strength | 320 MPa | 450 MPa |

| Yield Strength | 240 MPa | 380 MPa |

| Elongation | 16% | 14% |

| Hardness | 120 HV | 150 HV |

| Physical Properties | Value | Unit |

|---|---|---|

| Electrical Resistivity | 421 | nΩ·m |

| Specific Heat | 278 | J/kg·K |

| Coefficient of Thermal Expansion | 5.7 | 10⁻⁶/°C |

|

|

|

|

|

|

Physical and Chemical Properties

Zirconium is a highly reactive metal that forms a protective oxide layer when exposed to air, enhancing its corrosion resistance. It is non-toxic, has low thermal neutron absorption, and maintains its mechanical properties even under extreme heat. These unique attributes make zirconium ideal for applications in nuclear reactors, aerospace, and chemical processing where durability and reliability are critical.

- Melting Point: 1855°C

- Density: 6.52 g/cm³

- Thermal Conductivity: 22.7 W/m·K

- Corrosion Resistance: Excellent in both acidic and alkaline environments

- Oxidation Resistance: Forms a stable oxide layer at high temperatures, enhancing longevity in high-stress applications.

Product Features

-

High Corrosion Resistance: Zirconium’s ability to resist corrosion in aggressive environments, including acidic and alkaline solutions, makes it the material of choice for chemical processing and marine applications.

-

High-Temperature Stability: Zirconium can withstand extreme temperatures without compromising its mechanical properties, making it ideal for aerospace, nuclear, and high-temperature industrial applications.

-

Low Neutron-Capture Cross-Section: Zirconium’s unique ability to not absorb neutrons in nuclear applications makes it indispensable in nuclear power plants for fuel rod cladding and other components.

-

Exceptional Mechanical Strength: Zirconium exhibits high tensile and yield strength, which ensures durability in demanding applications.

-

Bio-Compatibility: Zirconium’s non-toxic and biocompatible properties make it an excellent material for medical implants and devices.

|

|

Applications

-

Nuclear Industry: Zirconium is critical for the nuclear industry due to its low neutron absorption rate and ability to function in extreme environments. It is commonly used in fuel rods, reactor components, and heat exchangers.

-

Aerospace: In aerospace engineering, zirconium components are valued for their strength, lightweight properties, and ability to perform under high temperatures and stress.

-

Chemical Processing: The chemical resistance of zirconium makes it ideal for use in piping, reactors, and pumps that come in contact with aggressive chemicals or corrosive environments.

-

Medical Devices: Zirconium’s biocompatibility is utilized in the production of medical implants, such as joint replacements, due to its resistance to corrosion and its ability to integrate with human tissues.

-

Power Generation: Zirconium's thermal and mechanical properties make it ideal for components in steam generators, turbines, and other high-temperature industrial applications.

|

|

Production Process

Shaanxi Peakrise Metal Co., Ltd. employs state-of-the-art technology and advanced production techniques to manufacture high-quality zirconium components. The production process includes:

- Raw Material Inspection: High-purity zirconium is sourced from trusted suppliers, ensuring the raw material meets stringent quality standards.

- Melting and Casting: Using vacuum arc melting furnaces and plasma electron beam melting techniques, we create zirconium alloys with superior mechanical properties.

- Forming: Advanced rolling mills and wire drawing machines are used to shape zirconium into custom components.

- Heat Treatment: Components undergo vacuum annealing to enhance their mechanical properties and relieve internal stresses.

- Precision Machining: CNC lathes, milling machines, and grinders are used to achieve precise dimensions and tolerances.

- Quality Control: Each product undergoes rigorous testing, including mechanical strength tests, corrosion resistance analysis, and dimensional accuracy checks.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Decades of Experience: Shaanxi Peakrise Metal has over 10 years of experience producing high-quality non-ferrous metals for global markets.

- Advanced Manufacturing Equipment: Our facility is equipped with the latest production technology, ensuring precision and consistency in every batch.

- Strict Quality Control: We adhere to international quality standards and conduct comprehensive testing at every stage of production.

- Custom Solutions: We offer tailored manufacturing solutions to meet specific customer requirements, including material properties, dimensions, and delivery schedules.

- Global Reach: We have established long-term relationships with customers in the USA, Germany, South Korea, and beyond, ensuring reliable global supply.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we provide comprehensive OEM and ODM services. Whether you require custom zirconium alloys, specific dimensions, or unique component designs, we can accommodate your needs. Our engineering team works closely with customers to develop products that meet exact specifications, ensuring seamless integration into their projects.

|

|

|

FAQ

-

What is the minimum order quantity for zirconium components?

The minimum order quantity depends on the specific product, but we typically accommodate small to large volume orders. -

Can you provide custom dimensions for zirconium products?

Yes, we offer custom manufacturing services to meet your exact specifications. -

What is the lead time for zirconium components?

Lead times vary based on order size and product complexity, but we typically deliver within 4-6 weeks. -

Do you offer certification for your zirconium products?

Yes, we provide material certifications and quality assurance documentation upon request. -

How do you ensure the quality of your zirconium components?

Every batch undergoes comprehensive quality testing, including mechanical strength assessments, corrosion resistance tests, and dimensional checks.

Packaging and Logistics

-

Packaging:

- Wooden Crates

- Carton Boxes

- Foam Padding for Shock Absorption

- Waterproof and Moisture-Proof Packaging

- Custom Packaging Solutions Available

- All packaging complies with international shipping standards.

-

Logistics:

- Ocean Freight

- Air Freight

- Road Transport

- Multimodal Shipping Solutions

- Express Courier Services

|

|

|

|

|

|

|

|

|

|

Contact Us

Ready to take your business to the next level with high-quality zirconium components? Shaanxi Peakrise Metal Co., Ltd. is your trusted partner for top-tier materials and custom solutions. Contact us today to discuss your needs and learn how we can support your projects. Reach out to us at info@peakrisemetal.com to get started!