molybdenum wire cut edm

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

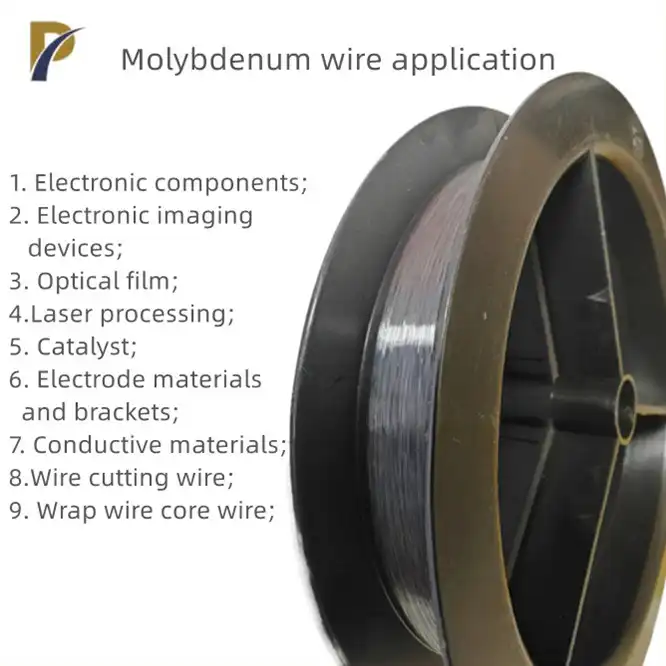

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Molybdenum Wire Cut EDM - Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing high-quality molybdenum wire cut EDM products that meet the demanding requirements of the global market. Our molybdenum wire cut EDM, crafted with precision and expertise, offers exceptional performance and reliability in various industrial applications. Molybdenum is renowned for its high melting point, excellent thermal conductivity, and superior strength, making it an ideal material for wire cut EDM processes.

Our molybdenum wire cut EDM products are manufactured using advanced techniques and rigorous quality control measures. As a leading supplier in the industry, Shaanxi Peakrise Metal Co., Ltd. ensures that each product meets the highest standards of quality and performance. Our commitment to excellence and customer satisfaction sets us apart as a trusted partner for businesses seeking reliable and efficient solutions in metal cutting and processing.

Product Parameters

Clean molybdenum wire is electropolished, and the surface should be clean, flat, bright and uniform in size. Mainly used for spiral filament, lead, support and other components mandrel.

Shaanxi Peakrise Metal can provide molybdenum wire with diameter Ø0.03~Ø2.0mm, we can also customize according to your requirements.

The use of molybdenum is not large. The vacuum tube is mainly used to make cathodes, anodes, and wire-cut molybdenum wires are used in inert gas protection environments. high temperature.

| Diameter (mm) | Mo content (%) | Tolerance (mm) | Weight (kg) | Length (m) | Coil diameter(mm) |

| 1.41~1.50 | 99.95 | +0/-0.04 | 4-10 | 250-600 | 450~600 |

| 1.51~1.62 | 99.95 | +0/-0.04 | 4-10 | 220-480 | 450~600 |

| 1.91~2.00 | 99.95 | +0/-0.04 | 5-12 | 170-380 | 450~600 |

| 2.21~2.30 | 99.95 | +0/-0.05 | 5-12 | 130-280 | 450~600 |

| 2.31~2.40 | 99.95 | +0/-0.05 | 6-16 | 130-350 | 600 |

| 3.10~3.18 | 99.95 | +0/-0.05 | 6-16 | 80-200 | 600 |

|

|

|

Physical and Chemical Properties

- Melting Point: Molybdenum has an exceptionally high melting point of 2620°C, ensuring stability and performance even at elevated temperatures.

- Density: With a density of 10.28 g/cm³, molybdenum offers robustness and durability, essential for wire cut EDM applications.

- Thermal Conductivity: Molybdenum exhibits excellent thermal conductivity, making it ideal for efficient heat dissipation during the EDM process.

- Electrical Resistivity: The material’s electrical resistivity of 5.0 µΩ·cm ensures reliable electrical performance during machining.

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | Ni | Si | Fe | Sn | Ca | Bi | Mg | Cd | Al | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | N | Sb | Pb | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Functions

- High Melting Point: Molybdenum’s high melting point allows it to withstand intense heat and pressure, making it suitable for high-precision wire cut EDM operations.

- Thermal Conductivity: Excellent thermal conductivity ensures efficient heat management, reducing the risk of thermal damage during the EDM process.

- Strength and Durability: The material’s superior strength and durability enhance the longevity and performance of EDM tools, resulting in cost-effective and reliable machining.

|

|

|

Product Applications

- Precision Machining: Molybdenum wire cut EDM is extensively used in precision machining of complex geometries, including intricate components for aerospace, automotive, and electronics industries.

- Tool Manufacturing: The material is ideal for manufacturing high-performance cutting tools and dies, thanks to its strength and thermal properties.

- Medical Devices: Molybdenum wire cut EDM is employed in the production of medical device components that require precise and reliable machining.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer with extensive experience in the production of tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel non-ferrous metals. Our state-of-the-art facility is equipped with cutting-edge technology and adheres to stringent quality control standards to deliver exceptional products. Our expertise and commitment to innovation make us a reliable partner for your metal processing needs.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We ensure secure and efficient packaging of our molybdenum wire cut EDM products to prevent damage during transportation. Our logistics team is dedicated to timely delivery, providing global shipping options to meet your requirements.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

Expertise: We have extensive experience in producing high-quality non-ferrous metals, including molybdenum.

Advanced Technology: Our production processes utilize the latest technology to ensure superior product performance.

Quality Assurance: Rigorous quality control measures guarantee that our products meet the highest standards.

Customer Support: Our dedicated team is available to assist with inquiries and provide expert advice.

Frequently Asked Questions

-

What is the maximum diameter available for molybdenum wire cut EDM?

- We offer diameters ranging from 0.1 mm to 1.0 mm.

-

What are the benefits of using molybdenum for wire cut EDM?

- Molybdenum provides high melting point, excellent thermal conductivity, and superior strength, making it ideal for precision machining.

-

Can I request a sample before placing a large order?

- Yes, we provide samples for evaluation upon request.

Call to Action

Ready to enhance your machining precision with high-quality molybdenum wire cut EDM? Contact us today to discuss your requirements and receive a customized solution. Reach out to our team at info@peakrise-metal.com for more information and to place your order.

Feel free to adjust any details or ask if you need additional sections or information!

YOU MAY LIKE

-

VIEW MOREmolybdenum copper alloy heat sink

VIEW MOREmolybdenum copper alloy heat sink -

VIEW MOREtungsten molybdenum alloy

VIEW MOREtungsten molybdenum alloy -

VIEW MORE0.1mm molybdenum sheet /plate

VIEW MORE0.1mm molybdenum sheet /plate -

VIEW MOREmolybdenum alloy strip foil

VIEW MOREmolybdenum alloy strip foil -

VIEW MOREnickel crucible 100ml

VIEW MOREnickel crucible 100ml -

VIEW MOREelectric furnace sic heating element

VIEW MOREelectric furnace sic heating element -

VIEW MORE99.95% white color molybdenum wires bright molybdenum wire

VIEW MORE99.95% white color molybdenum wires bright molybdenum wire -

VIEW MOREZr 702 cylindrical zirconium crucible

VIEW MOREZr 702 cylindrical zirconium crucible