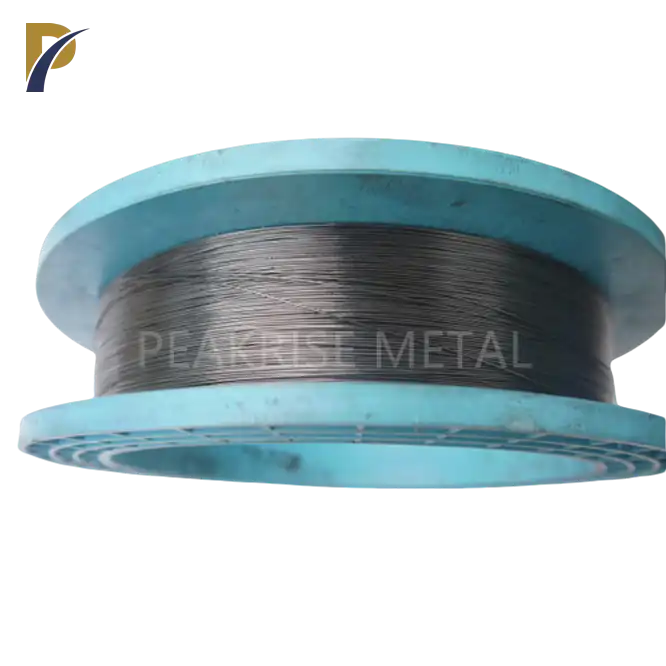

molybdenum cutting wire for lcd separator

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

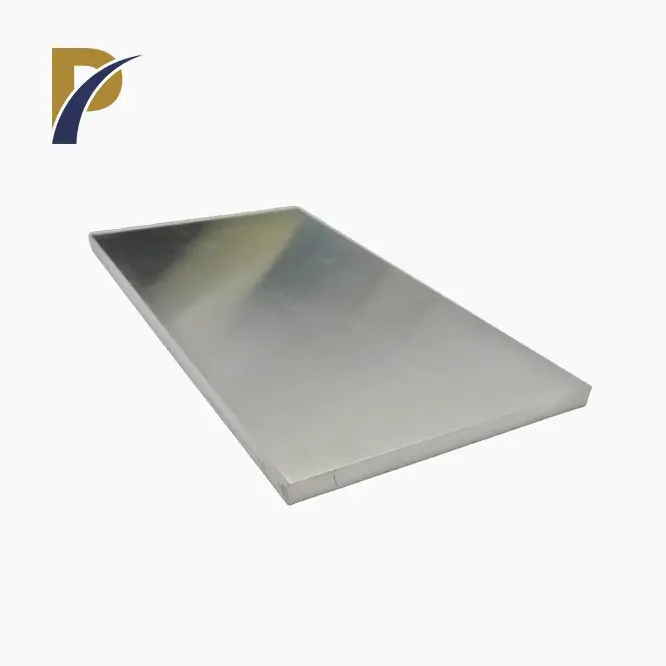

Molybdenum Cutting Wire for LCD Separator

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. specializes in the production of high-quality molybdenum cutting wire designed for LCD separator applications. As a leading supplier in the non-ferrous metal industry, we are dedicated to providing premium products that meet the rigorous demands of modern electronics manufacturing. Our molybdenum cutting wire is engineered to deliver exceptional performance in the precise and demanding task of separating LCD panels.

Molybdenum cutting wire is renowned for its superior tensile strength and resistance to thermal stress, making it ideal for delicate tasks such as cutting and separating LCD panels without causing damage to the sensitive components. At Shaanxi Peakrise Metal Co., Ltd., we leverage advanced manufacturing techniques and stringent quality control to ensure that our molybdenum cutting wire consistently meets the highest industry standards.

Our wire is designed to offer precise cutting capabilities, contributing to increased efficiency and reduced waste in the LCD manufacturing process. With a focus on quality and reliability, we aim to be the preferred choice for customers seeking durable and high-performance cutting solutions in the global market.

|

|

|

Product Parameters

| Parameter | Value |

|---|---|

| Wire Diameter | 0.1 mm - 0.5 mm |

| Tensile Strength | ≥ 1000 MPa |

| Melting Point | 2620°C |

| Density | 10.2 g/cm³ |

| Elongation | ≥ 5% |

| Electrical Resistivity | 5.2 µΩ·cm |

| Thermal Conductivity | 138 W/(m·K) |

| Name | Specific properties | Application |

| Molybdenum wire electrolytic cleaning | Electrolysis can be removed | mandrel curl |

| Molybdenum wire hydrogen cleaning | Can remove hydrogen from the atmosphere | For making different types of bulb holders |

Physical and Chemical Properties

Molybdenum cutting wire exhibits several critical properties:

- High Melting Point: Molybdenum's melting point of 2620°C allows it to withstand high temperatures during the cutting process.

- Excellent Tensile Strength: The wire maintains structural integrity under significant stress, ensuring precision and durability.

- Thermal Conductivity: Effective heat dissipation minimizes thermal damage to the LCD panels during separation.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- LCD Panel Separation: Ideal for cutting and separating LCD panels in the manufacturing process.

- Semiconductor Industry: Utilized in various semiconductor applications where precision cutting is required.

- Electronics Manufacturing: Supports the production of high-quality electronic devices by providing reliable and clean separation of components.

|

|

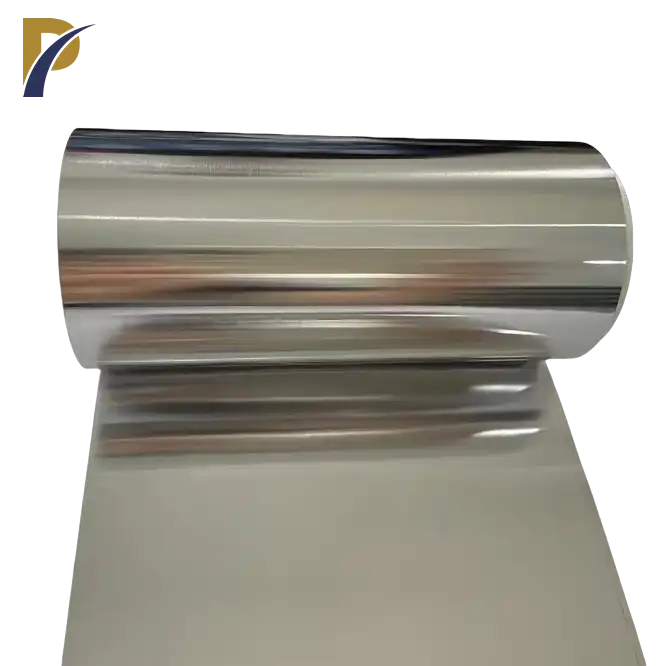

Manufacturing Process and Production Flow

- Material Sourcing: High-purity molybdenum is sourced from reliable suppliers.

- Wire Drawing: The molybdenum is drawn into fine wire using advanced machinery.

- Heat Treatment: The wire undergoes heat treatment to enhance its mechanical properties.

- Quality Inspection: Rigorous testing ensures compliance with industry standards.

- Packaging: The finished wire is carefully packaged to prevent damage during transport.

|

|

|

Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is a well-established non-ferrous metal production enterprise with extensive experience in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Our state-of-the-art manufacturing facilities are equipped with the latest technology to produce high-quality metal products, including tungsten-copper alloys and molybdenum-copper composites. Our commitment to innovation and quality ensures that we meet the diverse needs of our global clientele.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We prioritize secure and efficient packaging solutions to ensure that our products arrive in optimal condition. Our logistics team coordinates closely with shipping partners to provide timely delivery and track shipments from our facility to your location.

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: Extensive experience in producing high-quality non-ferrous metals.

- Advanced Technology: Use of cutting-edge manufacturing techniques.

- Quality Assurance: Rigorous quality control to ensure product excellence.

- Global Reach: Ability to meet the demands of international markets.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer OEM and ODM services to meet your specific requirements. Our team works closely with you to customize products according to your needs, ensuring that you receive tailored solutions that enhance your manufacturing processes.

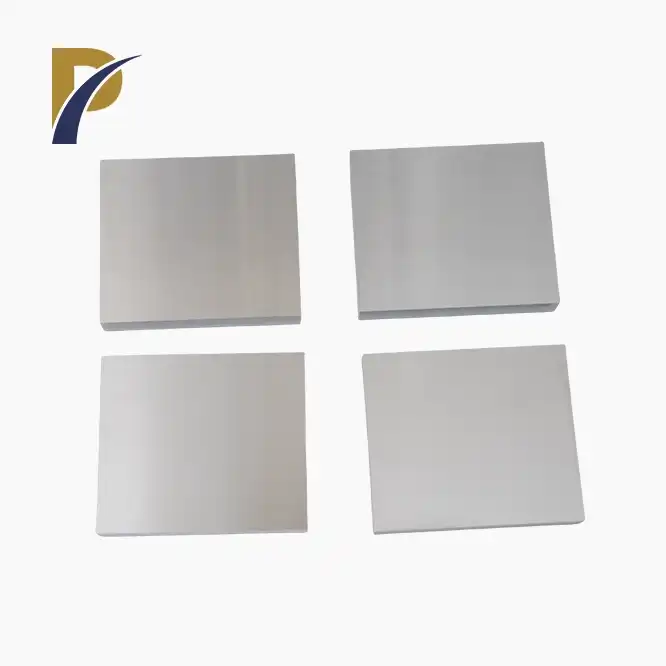

Products Produced By Shaanxi Peakrise Metal Co.,Ltd

|

|

|

|

|

|

|

|

|

Frequently Asked Questions

-

What is the typical diameter range for your molybdenum cutting wire?

- Our wire is available in diameters ranging from 0.1 mm to 0.5 mm.

-

How does molybdenum cutting wire compare to other materials?

- Molybdenum cutting wire offers superior strength and thermal stability compared to other materials, making it ideal for precision cutting tasks.

-

Can I request custom specifications for the wire?

- Yes, we provide OEM and ODM services to accommodate custom specifications.

Call to Action

Ready to enhance your LCD separation process with our high-performance molybdenum cutting wire? Contact us today to learn more about our products and how we can meet your specific needs. Get in touch info@peakrisemetal.com or request a quote now!

YOU MAY LIKE

-

VIEW MOREZirconium Wire for Specialized Applications

VIEW MOREZirconium Wire for Specialized Applications -

VIEW MOREHigh-Temperature Zirconium Foil

VIEW MOREHigh-Temperature Zirconium Foil -

VIEW MOREtungsten molybdenum wire

VIEW MOREtungsten molybdenum wire -

VIEW MOREmolybdenum tzm plate

VIEW MOREmolybdenum tzm plate -

VIEW MORElcd molybdenum cutting wire

VIEW MORElcd molybdenum cutting wire -

VIEW MOREtungsten-molybdenum alloy strip

VIEW MOREtungsten-molybdenum alloy strip -

VIEW MOREtungsten-molybdenum alloy tube

VIEW MOREtungsten-molybdenum alloy tube -

VIEW MOREmolybdenum glass melting electrodes

VIEW MOREmolybdenum glass melting electrodes