Zirconium Wire for Specialized Applications

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

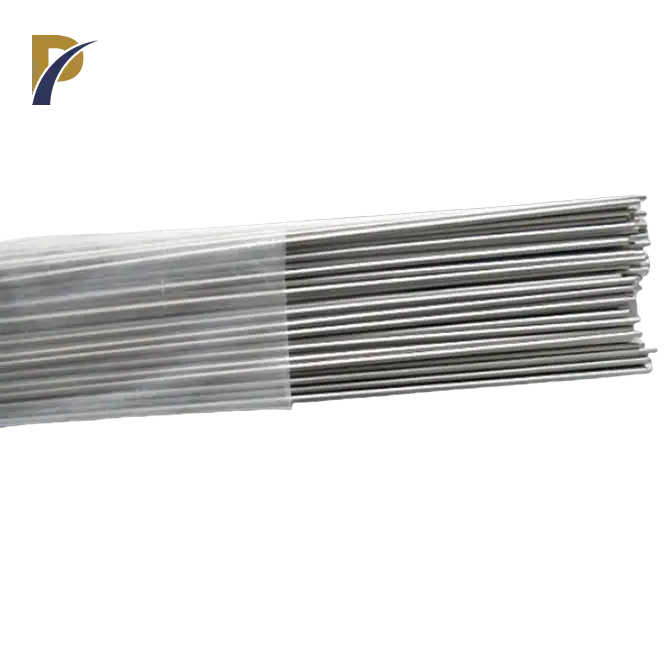

Zirconium Wire for Specialized Applications

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of zirconium wire for specialized applications, serving various industries with high-quality non-ferrous metal products. Our zirconium wire is meticulously designed to meet the diverse needs of sectors such as aerospace, nuclear, and medical applications, where durability and reliability are paramount.

Zirconium wire stands out due to its remarkable properties, including exceptional corrosion resistance, high strength, and excellent ductility. These attributes make it an ideal choice for environments that demand superior performance, such as chemical processing, oil and gas, and high-temperature applications.

At Shaanxi Peakrise Metal, we are committed to delivering products that not only meet but exceed our customers' expectations. Our zirconium wire is manufactured using state-of-the-art production techniques, ensuring that it meets stringent quality standards and performs reliably under extreme conditions. With years of experience in the non-ferrous metal industry, we have built a reputation for excellence, providing our clients with the confidence they need to choose our products for their specialized applications.

Our focus on quality and customer satisfaction drives us to continuously innovate and improve our processes. By leveraging our expertise in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel, we ensure that our zirconium wire stands out in the global market. We invite you to explore our offerings and discover how our zirconium wire can enhance your operations.

Product Specifications

| Property | Specification |

|---|---|

| Material Type | Zirconium (Zr) |

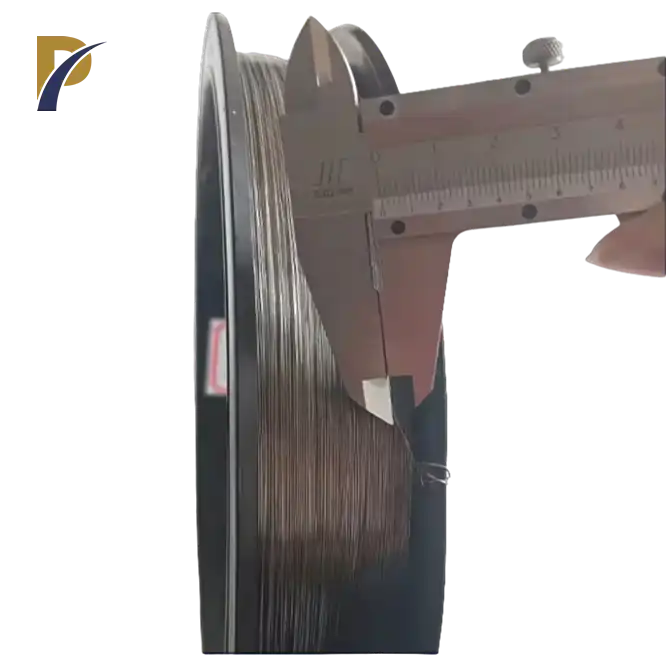

| Wire Diameter | 0.5 mm - 5 mm |

| Tensile Strength | ≥ 800 MPa |

| Elongation | ≥ 20% |

| Electrical Resistivity | 40 µΩ·cm |

| Melting Point | 1855 °C |

| Corrosion Resistance | Excellent |

| Chemical Composition | Percentage (%) |

|---|---|

| Zirconium (Zr) | 99.2 min |

| Oxygen (O) | 0.15 max |

| Nitrogen (N) | 0.02 max |

| Iron (Fe) | 0.05 max |

| Hydrogen (H) | 0.005 max |

| Manufacturing Process | Details |

|---|---|

| Sintering | Intermediate frequency furnace |

| Melting | Vacuum arc melting furnace |

| Wire Drawing | Multiple stages of drawing |

| Annealing | Vacuum annealing furnace |

| Quality Control | In-process and final testing |

|

|

Physical and Chemical Properties

Zirconium wire is known for its unique properties that make it suitable for specialized applications:

-

Corrosion Resistance: Zirconium exhibits remarkable resistance to a wide range of corrosive environments, including acidic and alkaline solutions. This makes it an excellent choice for chemical processing and nuclear applications.

-

High Strength-to-Weight Ratio: The material's strength allows for the production of thinner wires without compromising durability, enabling lighter designs in aerospace and automotive applications.

-

Biocompatibility: Zirconium is biocompatible, making it a preferred choice in medical devices and implants where interaction with biological tissues is critical.

-

Thermal Stability: With a high melting point, zirconium wire can maintain its integrity under extreme temperatures, ideal for applications in the aerospace and defense sectors.

-

Excellent Ductility: Zirconium wire can be easily manipulated and shaped without breaking, allowing for versatile applications across various industries.

|

|

Product Functions

-

Chemical Processing: Our zirconium wire is designed for use in chemical reactors and heat exchangers, where its corrosion resistance significantly extends the service life of equipment.

-

Nuclear Applications: Zirconium wire is essential in the nuclear industry for cladding fuel rods and other components, ensuring safety and efficiency.

-

Medical Devices: Due to its biocompatibility, our zirconium wire is used in various medical devices, including implants and surgical instruments, ensuring patient safety and effectiveness.

-

Aerospace Components: The lightweight and high-strength characteristics of zirconium wire make it an ideal material for aerospace applications, contributing to fuel efficiency and performance.

-

High-Temperature Applications: Zirconium wire maintains performance in extreme temperatures, making it suitable for use in various high-temperature applications, including furnace components and thermal insulation.

Product Applications

Zirconium wire plays a vital role in several industries, and its applications continue to expand as technology advances:

-

Chemical Industry: Used in reactors and pipelines, zirconium wire provides the corrosion resistance needed in harsh environments, ensuring operational safety and longevity.

-

Nuclear Power: Zirconium wire is crucial in the fabrication of fuel rods and other components, offering exceptional performance and reliability in nuclear reactors.

-

Aerospace: Its high strength and lightweight properties make zirconium wire ideal for aerospace applications, enhancing the efficiency and performance of aircraft and spacecraft.

-

Medical Field: Zirconium wire is increasingly used in medical devices due to its biocompatibility, facilitating the development of safe and effective surgical tools and implants.

-

Energy Sector: In oil and gas exploration, zirconium wire is used for downhole applications where durability and corrosion resistance are paramount, supporting the energy industry’s growing demands.

Manufacturing Process

Shaanxi Peakrise Metal Co., Ltd. employs a comprehensive manufacturing process for zirconium wire, ensuring the highest quality and performance:

-

Sintering: Using an intermediate frequency sintering furnace, zirconium powder is processed to form a solid mass, ensuring uniformity and density.

-

Melting: The vacuum arc melting furnace allows for the precise melting of zirconium, producing high-purity ingots free from contamination.

-

Wire Drawing: Multiple stages of drawing refine the wire to the desired diameter, ensuring consistency and strength.

-

Annealing: The wire undergoes vacuum annealing, which enhances ductility and reduces internal stresses, improving performance in applications.

-

Quality Control: Our dedicated quality control team conducts in-process and final testing to guarantee that each batch of zirconium wire meets our stringent specifications.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Company Overview

Shaanxi Peakrise Metal Co., Ltd. is an experienced production enterprise specializing in tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel non-ferrous metals. Our extensive product range includes over 100 varieties, such as tungsten-copper and molybdenum-copper alloys.

Founded in 2010, we recognized the potential for global market expansion and began focusing on foreign trade, providing high-quality products to international markets. Over the years, we have developed into a comprehensive production enterprise integrating manufacturing, processing, material research, product testing, and inventory management.

Our commitment to quality and service has led to long-term cooperative relationships with clients in various countries, including Taiwan, Ukraine, South Korea, the United States, Australia, Germany, and Iran. We pride ourselves on delivering high-quality products that meet our customers' expectations.

At Peakrise Metal, we boast an array of advanced production equipment, including sintering and melting furnaces, laser cutters, rolling mills, wire drawing machines, and CNC equipment. This technological edge allows us to maintain high standards in product quality and service.

Logistics and Packaging

Packaging Options

- Wooden Crate Packaging: Ensures protection during transit, suitable for heavy and delicate items.

- Carton Packaging: Lightweight and cost-effective, ideal for smaller orders.

- Foam-filled Packaging: Provides additional cushioning to prevent damage during transportation.

- Waterproof and Moisture-proof Packaging: Protects against environmental factors during shipping.

- Custom Packaging: Tailored to specific customer needs and requirements.

- International Standard Packaging: Complies with global shipping regulations to ensure safe delivery.

Logistics Solutions

- Sea Freight: Cost-effective for bulk orders, ensuring safe and reliable delivery across international waters.

- Air Freight: Ideal for urgent shipments, providing fast delivery times to various destinations.

- Land Transport: Efficient for regional deliveries, ensuring timely arrival.

- Multimodal Transport: Combines different transport methods for optimal efficiency and cost-effectiveness.

- Express Services: Offers expedited shipping for urgent orders, ensuring prompt delivery.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: With years of experience in the non-ferrous metal industry, we understand the unique needs of our customers and deliver tailored solutions.

- Quality Assurance: Our rigorous quality control processes guarantee that our zirconium wire meets the highest industry standards.

- Comprehensive Services: From manufacturing to logistics, we offer a complete range of services, ensuring a seamless experience for our clients.

- Global Reach: Our products are exported worldwide, and we have established long-term relationships with clients in various regions.

- Innovative Solutions: We continuously invest in research and development to provide cutting-edge products that meet evolving market demands.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we understand the importance of customization. We offer OEM and ODM services to meet the unique needs of our clients. Our team works closely with customers to develop tailored solutions that align with their specifications and requirements. Whether you need specific dimensions, packaging, or additional services, we are here to assist you in achieving your goals.

|

|

Contact us

Ready to enhance your high-temperature processes with our top-quality zirconium wire? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss your requirements and discover how we can provide the perfect solution for your needs. Reach out to us at info@peakrisemetal.com and take the first step towards superior performance and reliability in your applications.

We look forward to partnering with you for success!