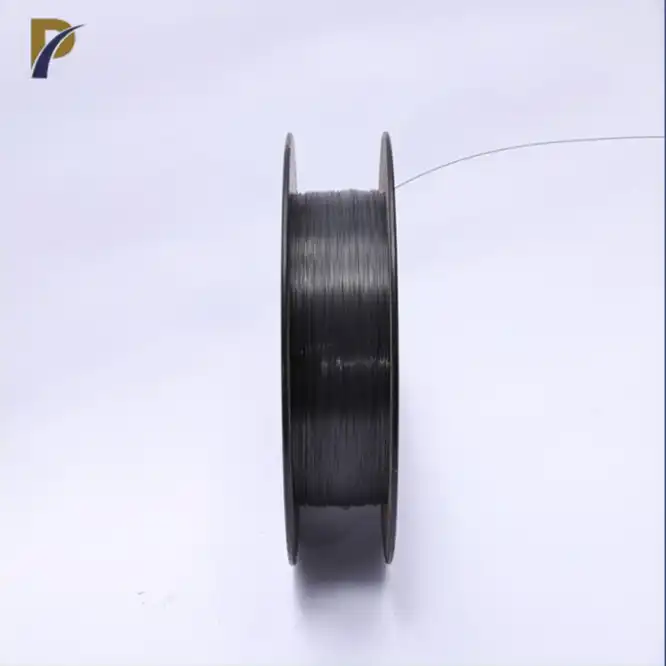

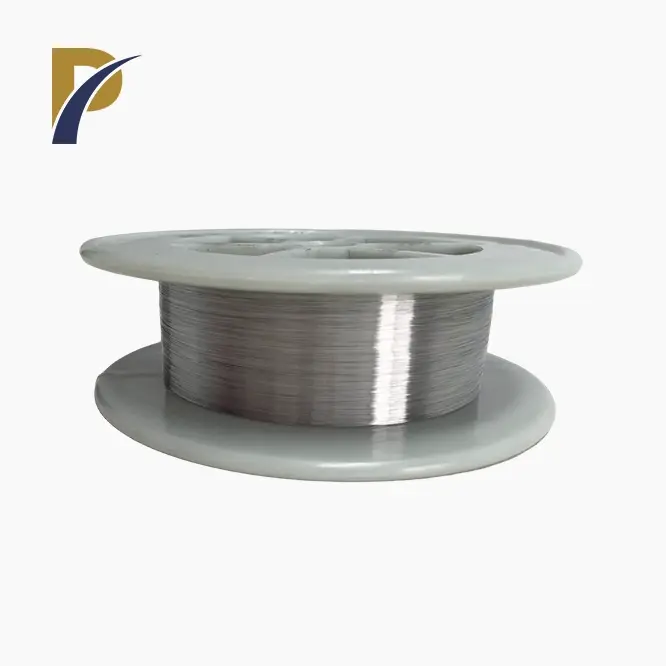

lcd molybdenum cutting wire

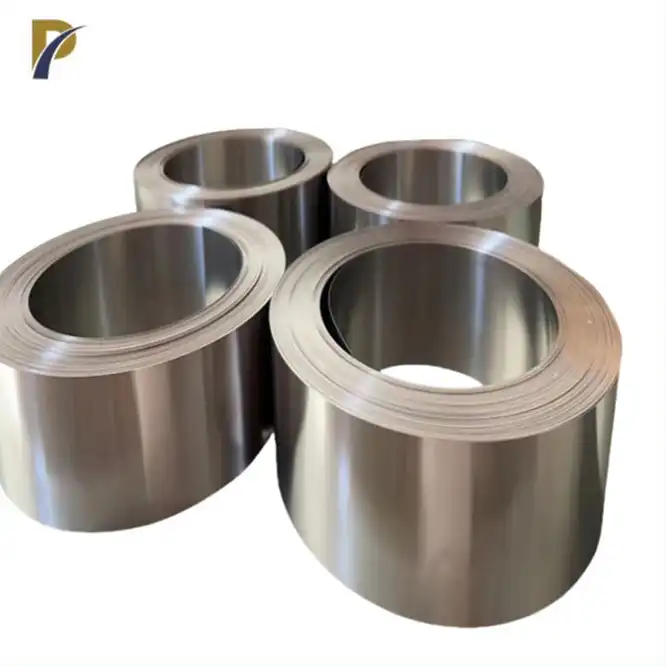

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

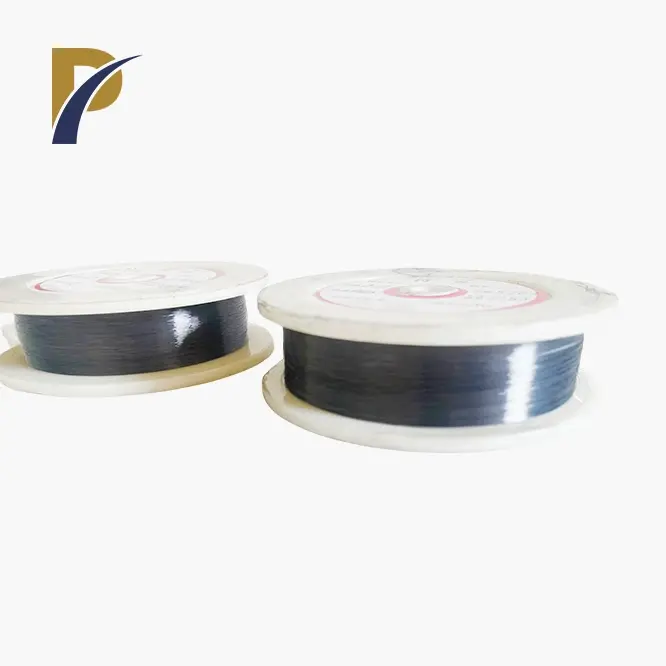

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

LCD Molybdenum Cutting Wire Product Introduction for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

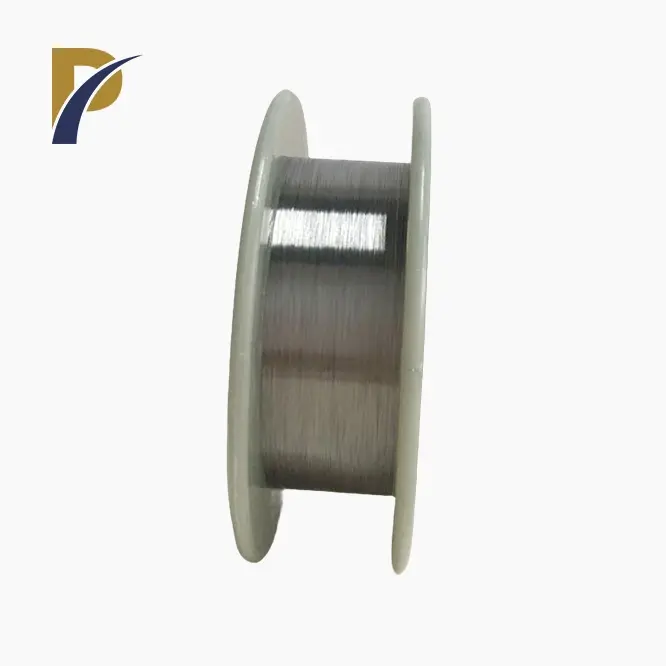

Shaanxi Peakrise Metal Co., Ltd. proudly introduces our high-quality LCD molybdenum cutting wire, a specialized product designed to meet the rigorous demands of precision cutting in the electronics and display industries. Molybdenum cutting wire is crucial for LCD (Liquid Crystal Display) manufacturing, particularly for cutting and separating glass substrates used in screens. Known for its high strength, superior conductivity, and wear resistance, our molybdenum wire ensures clean, accurate cuts, minimizing waste and optimizing production efficiency.

With years of experience in the non-ferrous metals industry, Shaanxi Peakrise Metal Co., Ltd. has become a leading global supplier of molybdenum products. We produce cutting wire that offers excellent performance, particularly in precision applications like LCD manufacturing, semiconductor processing, and photovoltaic cell production. Our product guarantees high tensile strength, uniform diameter, and a long service life, making it the perfect choice for manufacturers seeking consistent and reliable results.

|

|

|

Product Parameters Table

| Parameter | Value |

|---|---|

| Diameter Range | 0.06 - 0.35 mm |

| Tensile Strength | 2000 - 2700 MPa |

| Electrical Conductivity | ≥ 30% IACS |

| Melting Point | 2620°C |

| Density | 10.2 g/cm³ |

| Length per Spool | Customizable (up to 20,000 meters) |

Physical and Mechanical Properties

| Property | Specification |

|---|---|

| Thermal Conductivity | 138 W/m·K |

| Coefficient of Expansion | 4.8 x 10⁻⁶ K⁻¹ |

| Surface Finish | Bright, Smooth |

| Hardness | 240 - 260 HV |

| Oxidation Resistance | Excellent at high temperatures |

Product Applications

Our LCD molybdenum cutting wire is designed to serve various industries that require precision cutting and high-performance materials. Below are key applications:

-

LCD Manufacturing: Ideal for cutting glass substrates in LCD screens, ensuring precision and minimizing micro-cracks, which helps in extending the life of display devices.

-

Semiconductor Processing: Used in slicing semiconductor wafers, offering clean cuts with minimal waste and increased yield.

-

Photovoltaic Cells: Molybdenum wire is highly effective in cutting silicon wafers for solar panels, providing excellent electrical conductivity and resistance to wear.

-

Optical Devices: Precision cutting for high-quality optical lenses and devices that require minimal tolerance variations.

|

|

Product Functions

Our molybdenum cutting wire offers a range of functions tailored to enhance its utility in precision-based industries:

-

Precision Cutting: The high tensile strength and smooth surface ensure accurate, high-quality cuts with minimal deviation.

-

Wear Resistance: The durability of molybdenum allows for prolonged use without significant wear, reducing operational costs and downtime.

-

High Conductivity: Provides excellent electrical conductivity, making it suitable for applications in electrical discharge machining (EDM) and related processes.

-

Heat Resistance: With a high melting point and resistance to thermal deformation, it is perfect for high-temperature cutting applications.

-

Low Thermal Expansion: The minimal expansion of molybdenum ensures consistent results even in varying temperature conditions.

|

|

Product Process and Production Flow

Shaanxi Peakrise Metal Co., Ltd. implements a rigorous production process to ensure the highest quality standards for our molybdenum cutting wire:

-

Raw Material Selection: Only the finest quality molybdenum raw materials are sourced from certified suppliers.

-

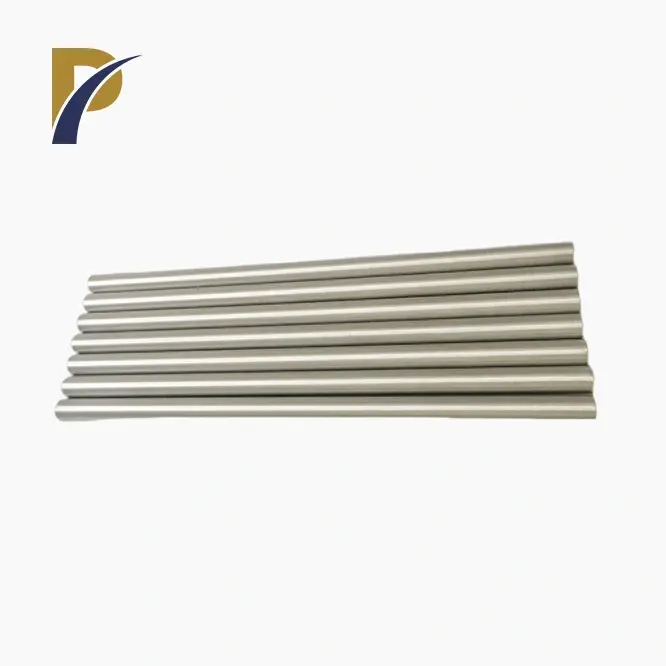

Melting and Casting: Using advanced vacuum arc melting furnaces to create high-purity molybdenum rods.

-

Wire Drawing: Precision wire drawing machines are used to achieve the desired diameter with uniformity throughout the spool.

-

Annealing: Our wire undergoes controlled vacuum annealing to improve ductility and tensile strength.

-

Quality Testing: Each batch is subjected to strict quality control tests, including tensile strength, diameter consistency, and surface finish checks.

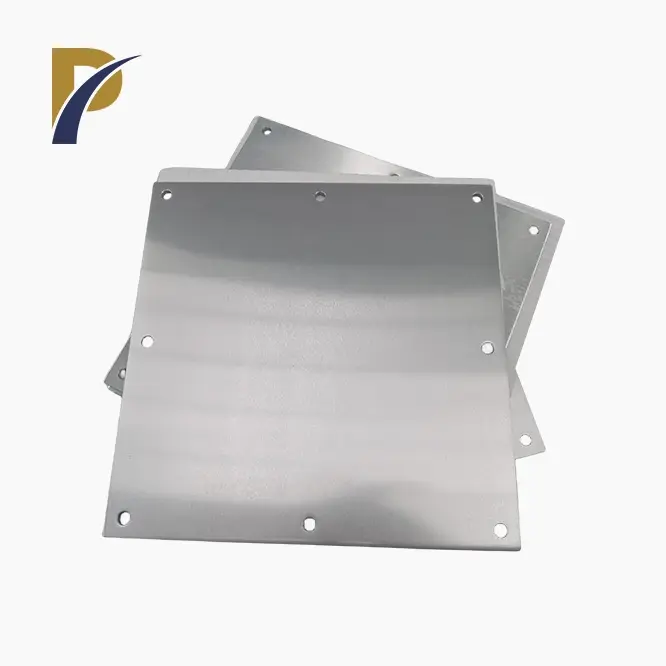

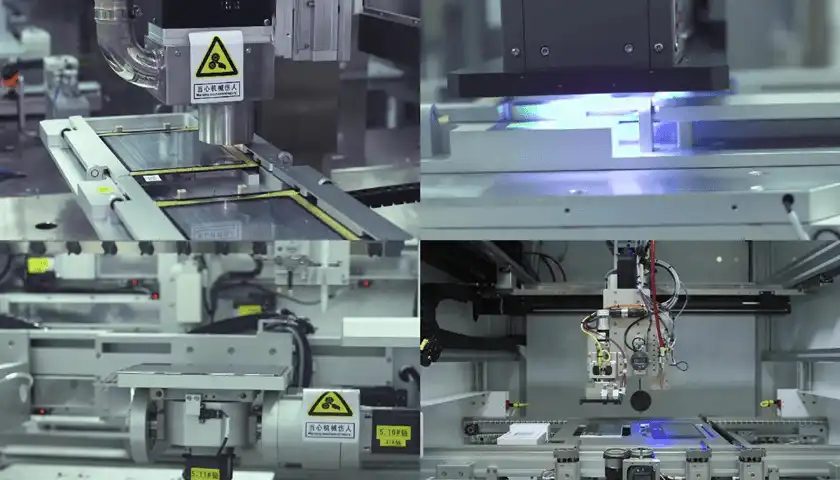

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a leading non-ferrous metal production enterprise with over a decade of expertise. We are equipped with state-of-the-art machinery, including intermediate frequency sintering furnaces, laser cutters, wire drawing machines, and CNC equipment. Our 10,000-square-meter facility is designed for efficient production and high output, meeting the demands of global markets with high-quality molybdenum and tungsten products.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We ensure that our products are delivered safely and securely through the following packaging options:

- Wooden crate packaging for heavy loads.

- Carton and foam-filled packaging for extra protection.

- Waterproof and moisture-proof wrapping for long-distance shipping.

- Custom packaging options available upon request.

|

|

|

|

|

|

|

|

Our logistics network supports:

- Sea freight for bulk orders.

- Air freight for urgent shipments.

- Land transportation within domestic regions.

- Multimodal transport options for complex routes.

- Express courier services for smaller, high-value shipments.

Why Choose Us?

-

Expertise: Over a decade of experience in non-ferrous metal production, ensuring high-quality materials.

-

Advanced Equipment: Fully equipped with modern production and testing equipment for consistent results.

-

Customization: We offer tailor-made solutions, from wire diameter to spool length, to meet customer-specific needs.

-

Global Reach: Our products are trusted by clients worldwide, with exports to Taiwan, South Korea, Germany, and more.

-

Quality Assurance: ISO 9001 certified, ensuring that all products meet international quality standards.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we understand that each customer has unique needs. Our OEM/ODM services allow you to customize molybdenum cutting wire to specific dimensions, tensile strength, and packaging requirements. Whether you need large-scale production or specialized small batches, we have the capacity and flexibility to deliver.

|

|

FAQ

-

What is the typical lead time for orders?

- Our standard lead time is 2-4 weeks, depending on order size and customization requirements.

-

Do you offer samples?

- Yes, we provide free samples for evaluation. Please contact us for details.

-

What is the minimum order quantity (MOQ)?

- The MOQ for molybdenum cutting wire is typically 5kg, but we can accommodate smaller requests.

-

Can I request custom specifications?

- Absolutely. We offer customization services to match your specific technical requirements.

-

What certifications do your products hold?

- All of our products are ISO 9001 certified and meet international standards for quality and performance.

Contact Us

Looking for a reliable supplier of LCD molybdenum cutting wire? Shaanxi Peakrise Metal Co., Ltd. is here to meet your needs. Our team of experts is ready to provide high-quality, customized solutions for your business. For more information or to request a quote, contact us at info@peakrisemetal.com. We look forward to working with you!