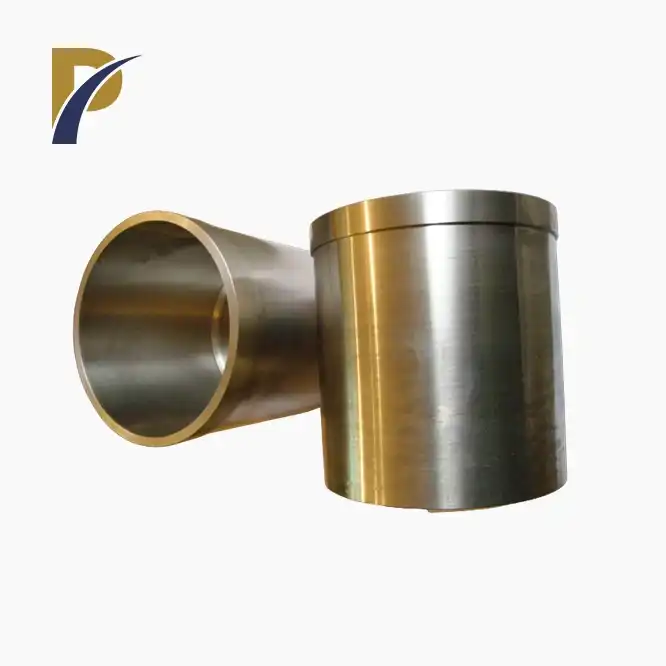

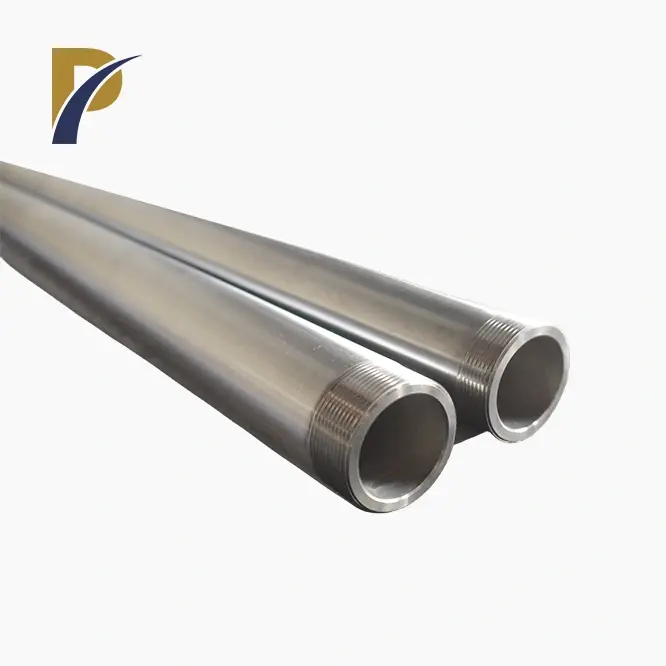

tungsten-molybdenum alloy tube

W Content: 50% (wt%)

Mo Content: 50% (wt%)

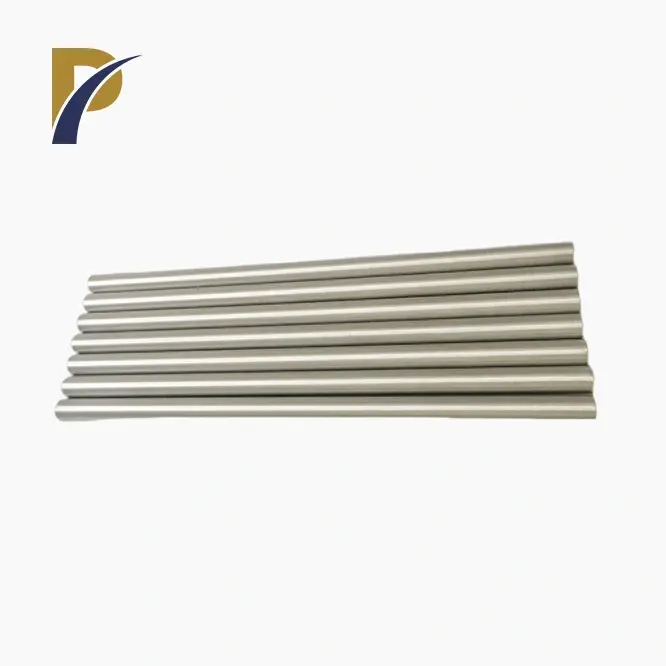

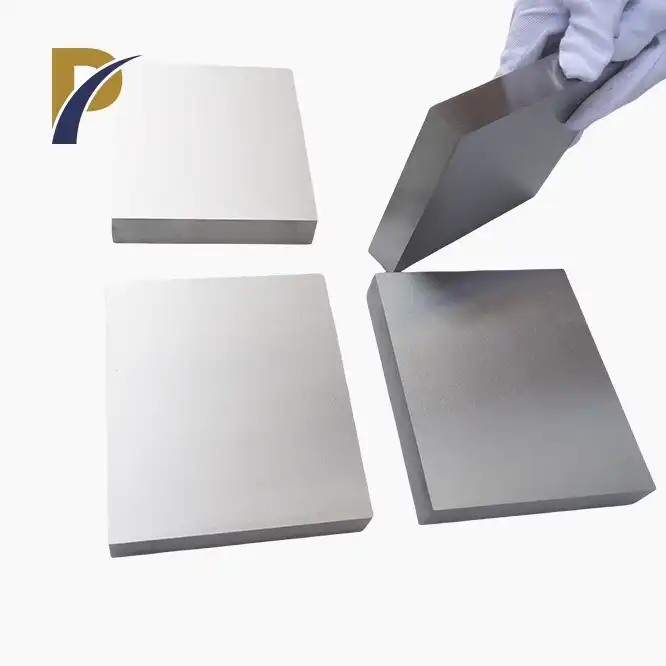

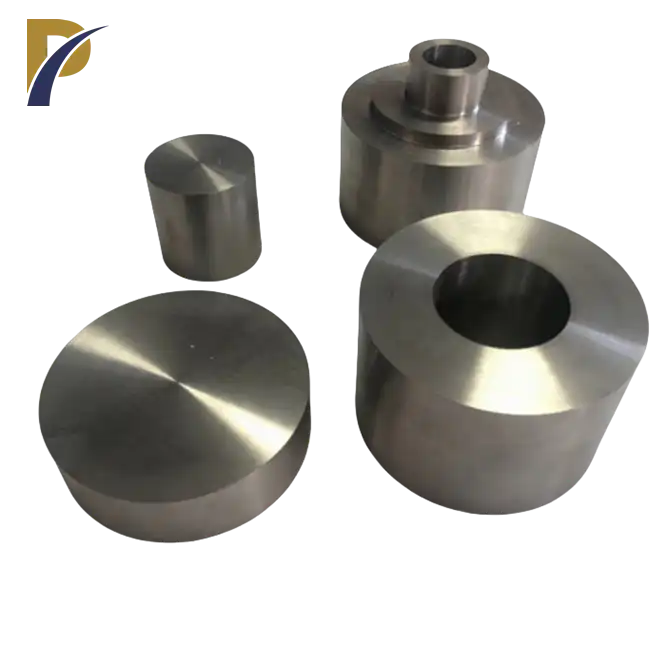

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Tungsten-Molybdenum Alloy Tube Product Introduction

Tungsten-molybdenum alloy tubes are highly specialized materials designed to withstand extreme environments and high temperatures, making them essential in industries such as aerospace, energy, and electronics. These tubes combine the high melting point of tungsten with the ductility and corrosion resistance of molybdenum, resulting in a material that offers superior performance in demanding applications. Shaanxi Peakrise Metal Co., Ltd. is a trusted supplier of tungsten-molybdenum alloy tubes, delivering high-quality products to meet the needs of global industries. Our company specializes in producing non-ferrous metals, with an extensive product portfolio that includes alloys made from tungsten, molybdenum, tantalum, niobium, and other high-performance materials.

With over a decade of experience in the export market, Shaanxi Peakrise Metal Co., Ltd. has grown into a comprehensive non-ferrous metal production enterprise, integrating manufacturing, material research, product testing, and stock inventory. Our commitment to quality and innovation has positioned us as a leading supplier, with products highly regarded by clients across Taiwan, Ukraine, South Korea, the United States, Germany, and many other countries. As a global leader in tungsten-molybdenum alloy tube manufacturing, we ensure that every product meets the highest industry standards, providing durability, precision, and reliability for a wide range of industrial applications.

Product Parameters

|

Out diameter |

Wall thickness |

Height |

|---|---|---|

| 26~750 mm | 5~30 mm | ≤1300 mm |

| Quantitative analysis | ||||||||||

| Element | W | Mo | Fe | Si | Ca | Mg | P | C | O | Al |

| Concentration(%) | 30 | 70 | 0.001 | 0.002 | 0.0006 | 0.0006 | 0.002 | 0.003 | 0.003 | 0.004 |

|

|

|

Physical and Mechanical Properties

Tungsten-molybdenum alloy tubes possess unique physical and mechanical properties that make them ideal for high-temperature applications. These tubes exhibit excellent thermal and electrical conductivity, a high melting point, and robust mechanical strength, ensuring durability in extreme conditions. The alloy’s ability to resist oxidation and corrosion also contributes to its longevity, making it a preferred material in industries that require reliability and performance under challenging environments.

|

|

Product Functions

- Heat Resistance: With a melting point exceeding 2600°C, tungsten-molybdenum alloy tubes are designed to perform efficiently in high-temperature environments such as furnaces and nuclear reactors.

- Corrosion Resistance: The molybdenum content in the alloy enhances its resistance to corrosion, making it suitable for use in harsh chemical environments.

- Electrical Conductivity: These tubes offer excellent electrical conductivity, making them useful in electronic components, such as cathodes and heating elements.

- Durability: The alloy’s strength and hardness ensure that it maintains structural integrity, even under mechanical stress and extreme heat, making it highly durable for industrial use.

- Lightweight Yet Strong: Despite being lighter than pure tungsten, the alloy retains significant strength, offering a balance between weight reduction and mechanical performance.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Aerospace Industry: Tungsten-molybdenum alloy tubes are used in high-temperature components such as rocket nozzles, heat shields, and propulsion systems due to their exceptional heat resistance.

- Nuclear Industry: The tubes are ideal for nuclear reactors, where they serve as structural materials that withstand radiation and high heat without degrading.

- Electronics: Their excellent electrical conductivity makes them perfect for use in electronic devices, semiconductors, and vacuum tubes.

- Medical Equipment: Tungsten-molybdenum alloy tubes are used in medical imaging devices like X-rays and CT scanners because of their ability to absorb and reflect radiation efficiently.

- Energy Sector: These tubes are used in high-temperature furnaces, turbines, and heat exchangers, ensuring efficiency and durability in energy production processes.

|

|

Product Process and Production Flow

Shaanxi Peakrise Metal Co., Ltd. follows a rigorous production process to ensure the highest quality tungsten-molybdenum alloy tubes. The process begins with raw material selection, followed by melting in a vacuum arc furnace to eliminate impurities. The molten alloy is then cast into ingots, which undergo rolling, extrusion, and annealing to achieve the desired dimensions and mechanical properties. The final tubes are precisely machined, ensuring tight tolerances and smooth surface finishes, and are subjected to stringent quality control tests, including tensile strength, hardness, and chemical composition analysis.

Our Factory

At Shaanxi Peakrise Metal Co., Ltd., we operate a state-of-the-art facility equipped with advanced machinery such as vacuum arc melting furnaces, plasma electron beam melting systems, CNC machining centers, and annealing furnaces. Our production capabilities allow us to manufacture a wide range of tungsten-molybdenum alloy tubes to meet varying industry needs. We employ a highly skilled workforce and adhere to strict ISO 9001 quality standards, ensuring consistent product quality and customer satisfaction.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

-

Packaging Options:

- Wooden Crates

- Cardboard Boxes

- Foam-filled Protective Packaging

- Waterproof and Moisture-resistant Wrapping

- Custom Packaging for Specific Requirements

- International Standard Packaging

-

Logistics Services:

- Sea Freight

- Air Freight

- Land Transportation

- Multimodal Transport

- Courier Services

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Industry Experience: With over ten years of expertise in producing tungsten and molybdenum alloy products, we have the knowledge and skills to deliver top-quality products.

- Global Reach: We serve customers across multiple countries, establishing long-term partnerships with businesses in the U.S., Germany, and beyond.

- Advanced Manufacturing: Our facility is equipped with cutting-edge machinery, enabling us to meet complex customer specifications and ensure timely deliveries.

- ISO Certified: We follow stringent ISO 9001 quality management systems to ensure our products meet the highest international standards.

- Comprehensive R&D: We invest in research and development to innovate new solutions and improve product performance.

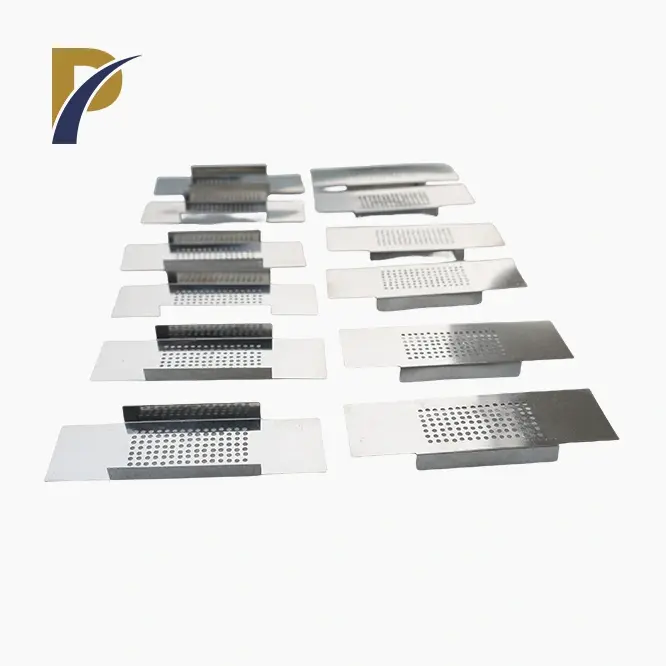

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers full OEM and ODM services, supporting clients in developing custom tungsten-molybdenum alloy tubes tailored to specific requirements. We work closely with our clients from concept to delivery, providing expert guidance on material selection, design, and production to achieve the best results.

|

|

|

|

|

|

|

|

|

FAQ

-

What are the delivery times for tungsten-molybdenum alloy tubes?

- Typically, the lead time is 4-6 weeks, depending on the order size and complexity.

-

Do you offer customization services?

- Yes, we provide complete OEM services to meet custom specifications for size, shape, and coatings.

-

Are your products ISO certified?

- Yes, all our products are manufactured under the ISO 9001 quality management system.

-

What industries use tungsten-molybdenum alloy tubes?

- Our tubes are commonly used in aerospace, electronics, nuclear energy, and medical industries.

-

What are your payment terms?

- We offer flexible payment terms, including T/T and L/C, to accommodate different customer needs.

Contact Us

For more information about our tungsten-molybdenum alloy tubes and to discuss how Shaanxi Peakrise Metal Co., Ltd. can support your project, please contact us at info@peakrisemetal.com. We welcome inquiries from global purchasers and look forward to establishing a long-term partnership.