tungsten-molybdenum alloy wire

W Content: 50% (wt%)

Mo Content: 50% (wt%)

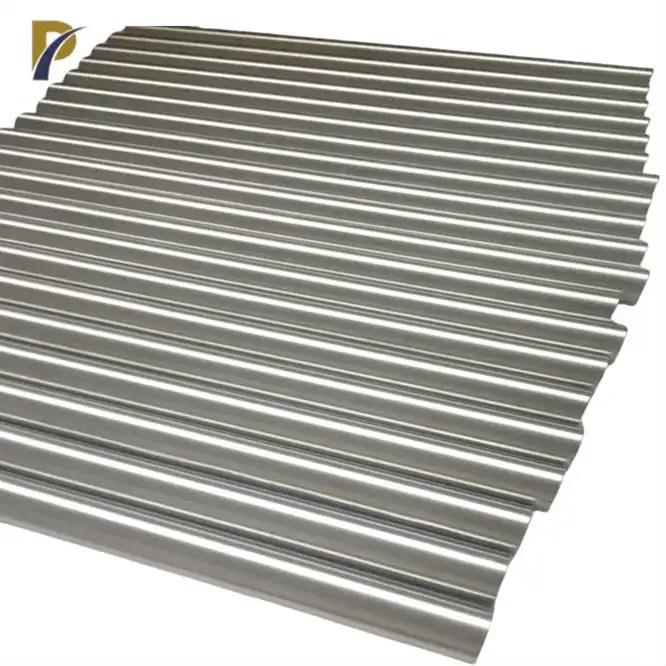

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

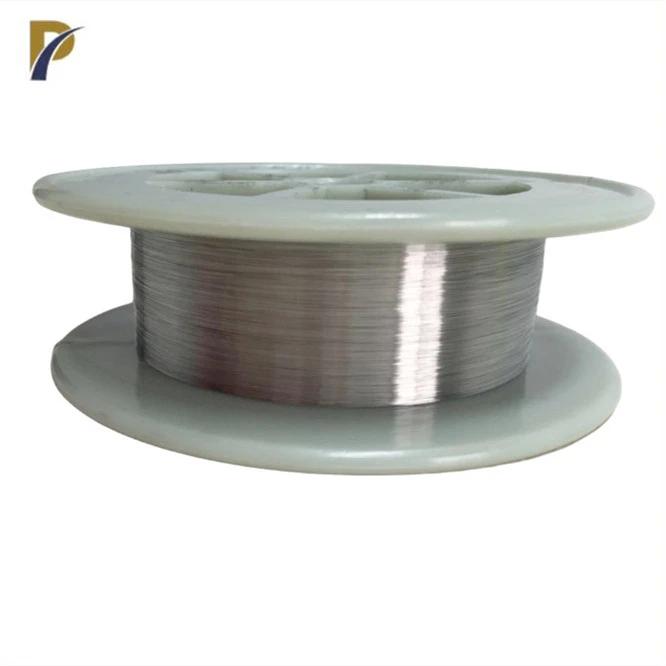

Tungsten-Molybdenum Alloy Wire: Product Introduction

Tungsten-molybdenum alloy wire is a highly specialized product in the field of high-temperature applications and extreme environments. With its superior physical and chemical properties, this alloy is widely used in industries such as aerospace, electronics, and energy. Tungsten-molybdenum alloys combine the high melting point and thermal conductivity of tungsten with the strength and oxidation resistance of molybdenum, making them ideal for applications requiring durability and stability under harsh conditions. These wires are essential in the manufacturing of filaments, electrical contacts, and other components exposed to extreme temperatures.

At Shaanxi Peakrise Metal Co., Ltd., we are a trusted supplier of high-quality tungsten-molybdenum alloy wire, offering customized solutions to meet the specific requirements of global industries. With over a decade of experience, we have established ourselves as a leading provider of non-ferrous metal products, catering to clients worldwide. Our commitment to quality, innovation, and customer satisfaction sets us apart in the market.

Product Parameters

| Parameter | Value |

|---|---|

| Diameter Range | 0.01mm - 2.0mm |

| Purity | ≥99.95% |

| Density | 10.2 - 19.3 g/cm³ |

| Tensile Strength | 800 - 1500 MPa |

| Melting Point (Tungsten) | 3410°C |

| Melting Point (Molybdenum) | 2617°C |

| Thermal Conductivity | 135 - 150 W/m·K |

| Electrical Resistivity | 5.43 × 10^-8 Ω·m |

|

|

|

Physical and Mechanical Properties

Tungsten-molybdenum alloy wire exhibits a unique combination of properties that make it suitable for high-performance applications:

- High Melting Point: With a melting point exceeding 3400°C, the wire performs exceptionally well in extreme temperatures.

- Thermal Stability: Its excellent thermal conductivity ensures efficient heat transfer, making it ideal for applications requiring thermal management.

- Oxidation Resistance: Molybdenum’s presence enhances the alloy’s resistance to oxidation, ensuring long-lasting performance in harsh environments.

- Mechanical Strength: The alloy’s tensile strength ensures durability and structural integrity, even under significant mechanical stress.

- Corrosion Resistance: This material is resistant to chemical corrosion, which enhances its lifespan in reactive environments.

Product Applications

Tungsten-molybdenum alloy wire is used across a wide range of industries, including:

- Lighting Industry: For the production of filaments in lighting systems, where high melting points and durability are essential.

- Aerospace Industry: Used in critical components such as engines, nozzles, and heat shields due to its thermal and mechanical resilience.

- Electronics Industry: Ideal for use in semiconductor components, circuit boards, and electrical contacts where precision and durability are key.

- Energy Sector: Deployed in high-temperature heating elements and nuclear reactors due to its high thermal conductivity and stability.

- Medical Equipment: Utilized in medical imaging devices and radiation shields, where its ability to withstand high energy exposure is essential.

|

|

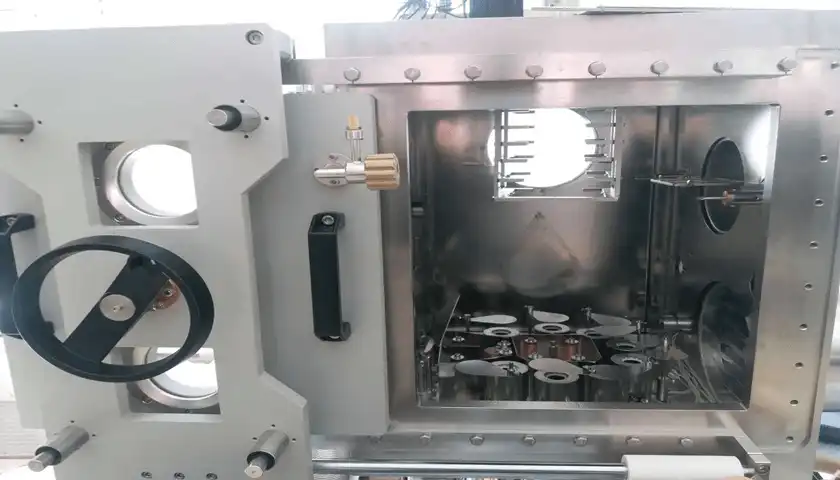

Product Process and Production Flow

Our tungsten-molybdenum alloy wire undergoes a rigorous production process to ensure the highest standards of quality:

- Material Selection: High-purity tungsten and molybdenum are selected and inspected for quality.

- Melting: The materials are melted in a vacuum arc furnace to create a uniform alloy.

- Forming: The alloy is drawn into wire form using specialized wire drawing machines, ensuring precision in diameter and consistency.

- Annealing: The wire is subjected to high-temperature annealing to enhance its mechanical properties.

- Quality Control: Each batch is tested for purity, tensile strength, and conductivity to meet stringent industry standards.

|

|

|

Our Factory

At Shaanxi Peakrise Metal Co., Ltd., we pride ourselves on having a world-class production facility equipped with state-of-the-art machinery, including vacuum arc melting furnaces, wire drawing machines, and plasma electron beam melting furnaces. Our factory adheres to strict quality control measures, ensuring that each product meets the highest industry standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We offer multiple packaging options to ensure the safe and secure delivery of our products:

- Wooden crates for heavy or large shipments.

- Carton packaging for smaller, lightweight shipments.

- Foam-filled packaging to protect against shock and vibration.

- Waterproof and moisture-proof packaging to ensure product integrity during transit.

- Custom packaging options are available to meet specific client requirements, all adhering to international shipping standards.

|

|

|

|

|

|

|

|

Our logistics services include:

- Sea freight, for cost-effective shipping of large quantities.

- Air freight, for faster delivery of smaller, urgent shipments.

- Land transportation within accessible regions.

- Multimodal transport, combining sea, air, and land options for the most efficient shipping routes.

- Courier services, for rapid, door-to-door delivery of smaller orders.

Why Choose Us?

- Experience: Over a decade of experience in non-ferrous metals, serving clients across multiple industries.

- High-Quality Products: We adhere to strict quality control standards, ensuring top-tier products.

- Advanced Facilities: Our factory is equipped with the latest technology, including vacuum furnaces and CNC machines.

- Global Reach: We export our products to over 10 countries, including the U.S., Germany, and South Korea.

- Customer-Centric: We work closely with clients to offer customized solutions, including OEM services.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. supports custom manufacturing services to meet specific client requirements. Whether you need specialized wire diameters, customized material compositions, or specific packaging, we have the capability to deliver.

|

|

FAQ

-

What is the minimum order quantity for tungsten-molybdenum alloy wire?

We have flexible minimum order quantities depending on the specific requirements of our clients. -

Can I request custom dimensions for the wire?

Yes, we offer custom diameters and lengths based on your specifications. -

How do you ensure the quality of the wire?

Our products undergo rigorous quality control, including tensile strength and purity tests. -

What are the payment terms?

We accept various payment methods, including T/T and L/C. -

How long does delivery take?

Delivery times vary based on the order size and destination but generally range from 2-4 weeks for standard orders.

Contact Us

Ready to explore how our tungsten-molybdenum alloy wire can benefit your business? Contact Shaanxi Peakrise Metal Co., Ltd. today at info@peakrisemetal.com for more information or to place an order. We look forward to serving your needs with high-quality, reliable products.