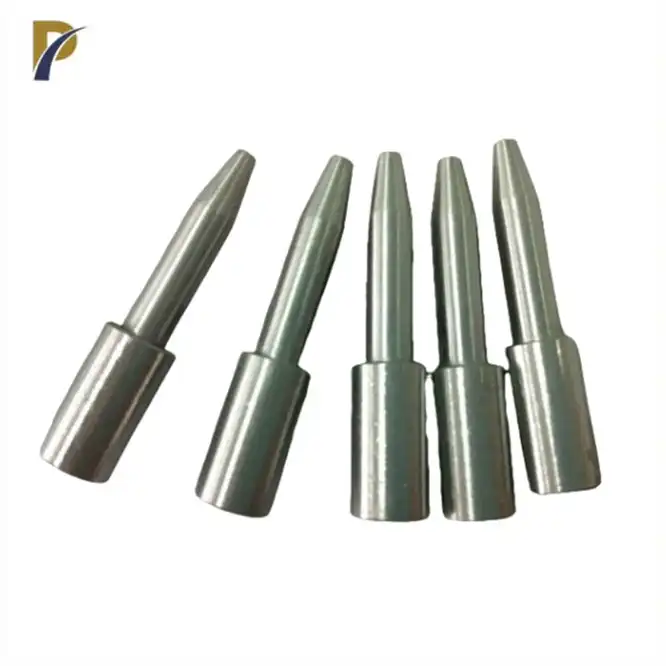

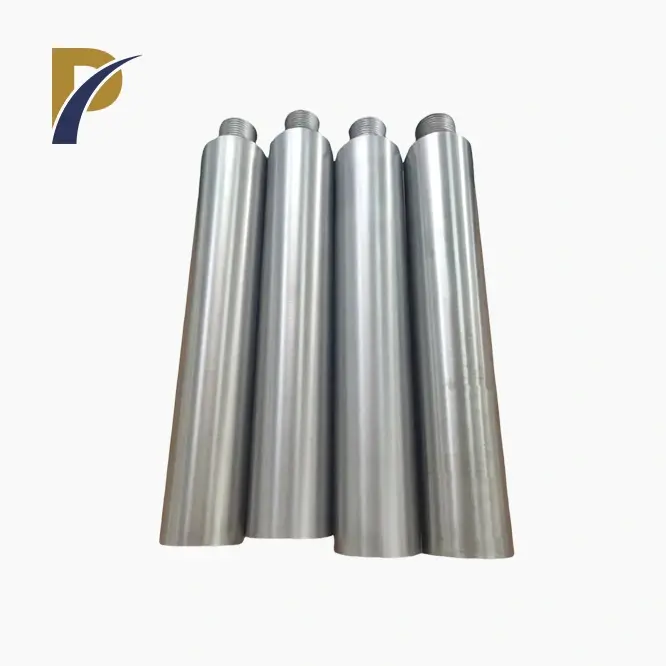

molybdenum edm electrode

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

Product Introduction

Molybdenum EDM electrodes are widely used in precision electrical discharge machining (EDM) applications due to their high melting point, excellent electrical conductivity, and exceptional wear resistance. These electrodes provide stable and efficient performance in high-precision machining environments, making them an ideal choice for manufacturers requiring superior quality and durability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | High-Purity Molybdenum (99.97%) |

| Diameter | 32mm, 50mm, 63mm, 75mm, 80mm, Custom Sizes Available |

| Length | Up to 2500mm |

| Surface Finish | Bright Metallic Silver |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

| Standard | ASTM B387 |

|

|

|

Features of molybdenum electrodes

High melting point, excellent conductivity, corrosion resistance, durability, high thermal conductivity, stability, efficient glass melting, reliable performance.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Precision engineered molybdenum electrodes to meet your specific needs!

At Peakrise Metal, your specific needs are our top priority. With over a decade of dedication, we expertly convert your intricate ideas into practical solutions using our precision-engineered molybdenum electrodes. From initial design to detailed specification modifications, each step of our manufacturing process is customized to fulfill your exact requirements.

The following customizations can be made when purchasing molybdenum electrodes:

- Size and shape: Customize the length, diameter and shape of the electrode according to specific application requirements to adapt to different equipment and operating conditions.

- Purity: Provide molybdenum materials with different purity levels according to customer requirements to meet the performance requirements of specific applications.

- Coating treatment: Add specific coatings to the electrode, such as anti-oxidation coating or conductive coating, to improve the performance and life of the electrode in specific environments.

- Connection method: Customize the connection method of the electrode according to the installation requirements of the equipment, such as threaded connection, flange connection, etc., to ensure convenient and stable installation.

- Packaging: Provide customized packaging solutions according to transportation and storage requirements to ensure the safety and integrity of the electrode during transportation.

Why choose molybdenum electrodes from Peakrise Metal?

At Peakrise Metal, we represent the highest industry standards through a perfect combination of advanced techniques, innovative technology, and unmatched expertise. Our steadfast commitment guarantees that your specific needs are expertly addressed with top-quality molybdenum electrode solutions.

Expertise and Experience: With over a decade in the industry, Peakrise Metal combines advanced technology and deep expertise to deliver high-quality molybdenum electrodes tailored to your precise needs.

Custom Solutions: We offer personalized solutions, including custom sizes, shapes, and coatings, ensuring our molybdenum electrodes meet the exact specifications and performance requirements of your application.

Unmatched Quality: Our commitment to superior manufacturing standards ensures that each molybdenum electrode delivers exceptional performance, durability, and reliability, providing excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Applications

Precision Electrical Discharge Machining (EDM) – Used in tool and die manufacturing.

Aerospace Industry – Machining of high-performance metal alloys.

Medical Equipment Manufacturing – Production of intricate components.

Electronics Industry – Fabrication of micro-scale components with high accuracy.

Automotive Industry – High-precision machining of complex metal parts.

Manufacturing Process

Powder Metallurgy – High-purity molybdenum powder is compacted and sintered.

Hot Rolling & Forging – Increases density and mechanical strength.

Precision Machining – Electrodes are shaped to exact specifications.

Quality Inspection – Each batch undergoes rigorous testing, including non-destructive testing (NDT) and dimensional analysis.

Quality Assurance

We ensure the highest quality standards by employing:

Advanced manufacturing techniques.

Strict raw material selection processes.

Multiple stages of quality control and testing.

FAQs

Q1: What is the lifespan of molybdenum EDM electrodes?

A: The lifespan depends on usage conditions, but molybdenum electrodes generally offer superior durability compared to copper and graphite electrodes.

Q2: Can I order custom diameters and lengths?

A: Yes, we offer custom sizes to meet your specific EDM machining requirements.

Q3: How does molybdenum compare to copper and graphite electrodes?

A: Molybdenum provides better wear resistance, higher temperature stability, and minimal thermal expansion, making it an excellent choice for precision applications.

Contact Us

For pricing and further inquiries, contact us today:

📧 Email: info@peakrisemetal.com

📱 WhatsApp: +8613186382597

Get the best molybdenum EDM electrodes for your machining needs – request a quote now!