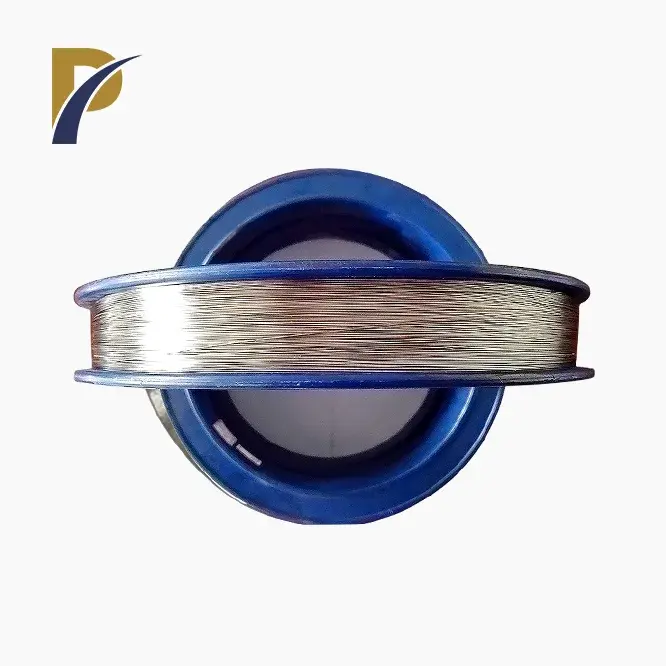

Industrial Grade Zirconium Wire

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Industrial Grade Zirconium Wire Product Page

Product Introduction

At Shaanxi Peakrise Metal Co., Ltd., we pride ourselves on being a leading supplier of industrial-grade zirconium wire, renowned for its high-quality performance and exceptional reliability in various applications. Our zirconium wire is manufactured using advanced technology and adheres to strict industry standards, ensuring that it meets the rigorous demands of modern manufacturing and engineering sectors.

Zirconium, known for its remarkable corrosion resistance, high melting point, and excellent mechanical properties, is increasingly becoming a material of choice in industries such as chemical processing, nuclear energy, and aerospace. The unique attributes of zirconium wire make it ideal for use in environments that demand superior performance under extreme conditions.

Our commitment to quality and innovation sets us apart in the market. With years of experience in non-ferrous metal production, Shaanxi Peakrise Metal Co., Ltd. has developed a comprehensive approach to manufacturing zirconium wire that focuses on customer satisfaction and product excellence. Whether you are looking for a reliable supplier for your industrial needs or seeking customized solutions, we have the expertise and resources to meet your requirements.

Product Specifications

| Specification | Value |

|---|---|

| Diameter | 0.1 mm - 5.0 mm |

| Tensile Strength | ≥ 600 MPa |

| Elongation | ≥ 15% |

| Melting Point | 1855 °C |

| Density | 6.52 g/cm³ |

| Corrosion Resistance | Excellent |

| Grade | Element composition(%)< | Standard | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | ||

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 | ASTM B550 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- | |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 | |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

Physical and Chemical Properties

Zirconium wire boasts an array of impressive physical and chemical properties that enhance its usability across various applications:

- Corrosion Resistance: Exceptional resistance to corrosion in acidic and alkaline environments, making it suitable for chemical processing.

- High Melting Point: With a melting point of 1855 °C, it retains structural integrity under extreme heat.

- Low Thermal Neutron Absorption Cross Section: Ideal for nuclear applications where minimal interference with neutron flow is crucial.

- Biocompatibility: Safe for medical applications, zirconium exhibits low toxicity and is compatible with biological systems.

|

|

|

Product Functions

-

Corrosion Resistance: The primary function of zirconium wire is its ability to withstand corrosive environments, making it a reliable choice for chemical reactors and piping systems.

-

High Strength: With a tensile strength exceeding 600 MPa, our zirconium wire is engineered to handle substantial mechanical stress without compromising integrity.

-

Thermal Stability: The high melting point allows the wire to maintain performance even in high-temperature applications, ensuring long-term reliability.

-

Low Neutron Absorption: Its low neutron absorption cross-section makes it suitable for use in nuclear reactors, allowing for effective operation without significant interference.

Product Applications

Industrial-grade zirconium wire finds extensive application across several key sectors:

- Chemical Industry: Utilized in the production of reactors, heat exchangers, and valves due to its superior corrosion resistance.

- Aerospace and Defense: Ideal for components exposed to extreme temperatures and corrosive atmospheres, enhancing the durability of aircraft and military equipment.

- Nuclear Energy: Employed in fuel cladding and structural materials, where low neutron absorption is critical.

- Biomedical: Used in medical devices and implants, capitalizing on its biocompatibility and corrosion resistance.

As industries evolve, the demand for zirconium wire is expected to grow, particularly in fields focused on sustainable energy and advanced manufacturing technologies.

Manufacturing Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., our manufacturing process for zirconium wire is designed to ensure precision and quality at every step:

- Material Sourcing: We source high-purity zirconium from trusted suppliers, ensuring the highest quality raw materials.

- Melting: The zirconium is melted using a vacuum arc melting furnace, minimizing impurities and achieving a homogenous material.

- Forming: The melted zirconium is then cast into ingots and subjected to various forming processes, including rolling and drawing, to achieve the desired wire diameter.

- Annealing: The wire is annealed in a vacuum annealing furnace to enhance its mechanical properties and remove residual stresses.

- Quality Control: Each batch undergoes rigorous testing to ensure it meets our high standards for strength, ductility, and corrosion resistance.

- Packaging: The finished wire is carefully packaged to prevent damage during transportation.

Company Introduction

Shaanxi Peakrise Metal Co., Ltd. is a seasoned enterprise specializing in the production of non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Our extensive product range includes more than 100 types of high-quality materials, catering to diverse industries worldwide.

Since 2010, we have shifted our focus to international trade, supplying premium non-ferrous metal products to markets across the globe, including Taiwan, Ukraine, South Korea, the United States, Australia, Germany, and Iran. Over the years, we have built strong relationships with our clients, earning their trust and satisfaction through consistent quality and service.

Our advanced production facilities feature a range of cutting-edge equipment, including:

- Intermediate frequency sintering furnaces

- Vacuum arc melting furnaces

- Laser cutters

- Plasma electron beam melting furnaces

- Various rolling mills and wire drawing machines

- CNC machining centers

This state-of-the-art infrastructure allows us to meet the evolving needs of our customers while ensuring the highest standards of quality and performance.

Packaging

We understand that effective packaging is crucial for maintaining product integrity during transit. Our packaging solutions include:

- Wooden Crate Packaging: For large and heavy shipments, ensuring durability and protection.

- Carton Packaging: Suitable for smaller orders, providing lightweight yet sturdy protection.

- Foam Fill Packaging: To prevent damage during transport, particularly for delicate items.

- Waterproof and Moisture-proof Packaging: Protecting against environmental factors.

- Custom Packaging: Tailored solutions based on specific customer requirements.

- International Standard Packaging: Compliance with global shipping regulations to ensure safe delivery.

|

|

|

|

|

|

|

|

Logistics

Shaanxi Peakrise Metal Co., Ltd. offers various logistics options to meet our customers' needs:

- Sea Freight: Economical solution for bulk shipments across oceans.

- Air Freight: Fast delivery for urgent orders, ensuring timely receipt of products.

- Land Transport: Reliable for domestic shipments and cross-border deliveries.

- Multimodal Transport: Combining various methods for efficient logistics solutions.

- Express Services: For urgent orders requiring quick dispatch.

Why Choose Us?

Choosing Shaanxi Peakrise Metal Co., Ltd. as your zirconium wire supplier comes with several advantages:

- Expertise: With rich experience in non-ferrous metal production, we possess extensive knowledge of materials and processes.

- Quality Assurance: We prioritize quality in every aspect of our operations, ensuring our products meet stringent industry standards.

- Customization: Our OEM and ODM services allow us to tailor solutions to meet specific client needs and requirements.

- Global Reach: Our established international network enables us to serve customers worldwide efficiently.

- Customer Focus: We are committed to understanding our clients' needs and providing exceptional service and support.

Frequently Asked Questions (FAQs)

-

What is the minimum order quantity for industrial-grade zirconium wire?

- Our minimum order quantity varies based on specific requirements. Please contact us for details.

-

Can you provide custom sizes for zirconium wire?

- Yes, we offer OEM services and can manufacture zirconium wire in custom sizes and specifications.

-

What is the lead time for orders?

- Lead times depend on order size and specifications. Typically, it ranges from 2 to 4 weeks.

-

What certifications do your products hold?

- Our products comply with international quality standards, and we can provide certification documentation upon request.

-

Do you offer technical support?

- Yes, our team provides technical support and guidance to assist with any inquiries or concerns regarding our products.

Call to Action (CTA)

At Shaanxi Peakrise Metal Co., Ltd., we are dedicated to providing you with high-quality industrial-grade zirconium wire that meets your specific needs. Contact us today at info@peakrisemetal.com to discuss your requirements and discover how we can support your projects with our exceptional products and services. Let's collaborate for success!

YOU MAY LIKE

-

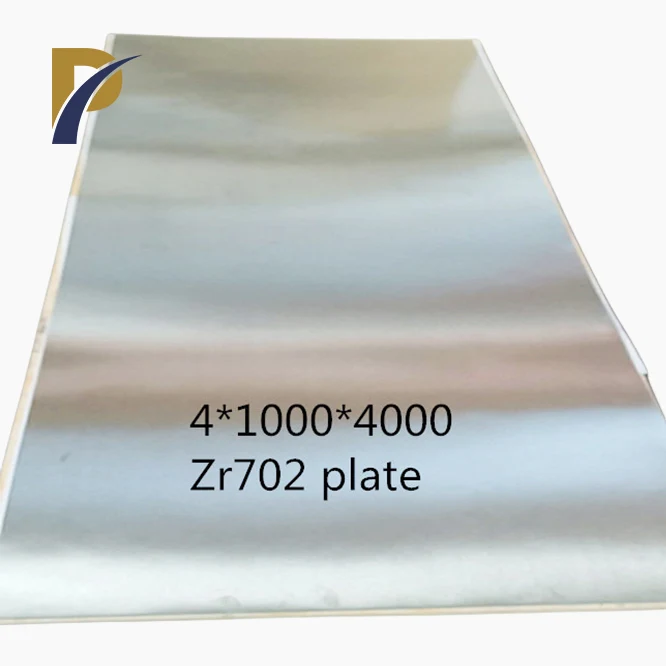

VIEW MOREZirconium Foil Sheets for Fabrication

VIEW MOREZirconium Foil Sheets for Fabrication -

VIEW MORECorrosion-Resistant Zirconium Tubes

VIEW MORECorrosion-Resistant Zirconium Tubes -

VIEW MOREZirconium Lab Crucible High Purity

VIEW MOREZirconium Lab Crucible High Purity -

VIEW MOREWedding Band Zirconium Ring

VIEW MOREWedding Band Zirconium Ring -

VIEW MOREERZr-4 Zr705 99.0% Purity Zirconium Alloy Welding Wire

VIEW MOREERZr-4 Zr705 99.0% Purity Zirconium Alloy Welding Wire -

VIEW MORECorrosion-Resistant Zirconium Sheets

VIEW MORECorrosion-Resistant Zirconium Sheets -

_1742884662735.webp) VIEW MOREZirconium Precision Cut Rods

VIEW MOREZirconium Precision Cut Rods -

VIEW MOREu type sic heating element

VIEW MOREu type sic heating element