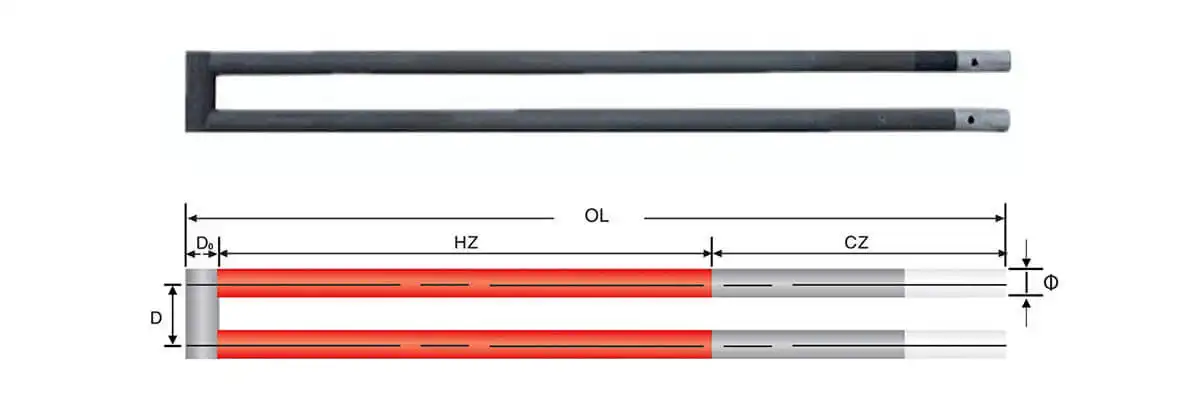

u type sic heating element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

U Type SiC Heating Element – A Comprehensive Solution for High-Temperature Applications

The basic characteristics of U-shaped silicon carbon rod: U-shaped silicon carbon rod is composed of two silicon carbon rods with equal radius and a common cold end. U-shaped silicon carbon rod can be connected to the power line at one end of the kiln. The surface temperature of the heating part is 1500℃. It is mainly used in high-temperature furnaces and kilns with high requirements for furnace temperature uniformity. Its characteristics are power saving and long furnace life.

Silicon Carbide (SiC) is known for its remarkable heat resistance and high conductivity, making it a preferred material for heating elements in industries like metallurgy, ceramics, and glass manufacturing. The U Type design enhances the heating efficiency by allowing more surface area for heat transfer, reducing energy consumption, and providing uniform temperature distribution. Whether it's for industrial furnaces or kilns, Shaanxi Peakrise Metal's U Type SiC Heating Element is engineered to deliver reliable and consistent performance.

Product Parameters Table

| Diameter ∅(mm) | HZ Length (mm) | CZ length(mm) | D | Bridge size | Resistance Range | |

| D0 | L3 | |||||

| 14 | 200 | 250 | 40 | 14 | 54 | 2.4-4.6 |

| 14 | 250 | 300 | 50 | 14 | 64 | 3.0-6.0 |

| 14 | 300 | 350 | 60 | 14 | 74 | 3.6-7.0 |

| 16 | 200 | 250 | 40 | 16 | 56 | 1.4-2.8 |

| 16 | 250 | 300 | 50 | 16 | 66 | 1.8-3.6 |

| 16 | 300 | 350 | 60 | 16 | 76 | 2.0-5.0 |

| 18 | 300 | 350 | 60 | 18 | 78 | 2.0-5.0 |

| 18 | 400 | 400 | 70 | 18 | 88 | 2.8-5.8 |

| 18 | 500 | 450 | 75 | 18 | 93 | 3.6-7.2 |

| 20 | 250 | 300 | 50 | 20 | 70 | 1.8-3.6 |

| 20 | 300 | 350 | 60 | 20 | 80 | 2.0-5.0 |

| 20 | 400 | 400 | 70 | 20 | 90 | 2.8-5.8 |

| 25 | 400 | 400 | 70 | 25 | 95 | 1.6-3.4 |

| 25 | 500 | 450 | 75 | 25 | 100 | 2.2-4.4 |

| 25 | 600 | 500 | 80 | 25 | 105 | 2.6-5.2 |

| 30 | 600 | 400 | 70 | 30 | 100 | 1.4-2.8 |

| 30 | 700 | 450 | 75 | 30 | 105 | 1.6-3.2 |

| 30 | 800 | 500 | 80 | 30 | 110 | 1.8-3.6 |

Advantages of U-shaped silicon carbon rods

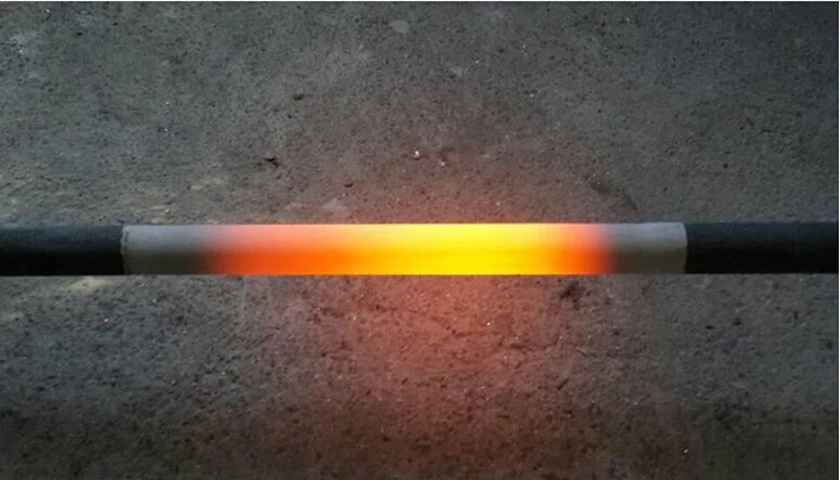

★ The maximum surface temperature can reach 1500℃

★ Durable and long working life

★ High strength and good shock resistance

★ No noise and air pollution, environmentally friendly

Physical and Mechanical Properties

The U Type SiC Heating Element is manufactured from high-purity silicon carbide, which ensures exceptional thermal conductivity and mechanical strength. The high hardness of SiC, combined with its resistance to thermal shock, allows the element to operate efficiently under extreme temperature changes. These heating elements also have an excellent oxidation resistance, ensuring longevity even in corrosive environments.

- Thermal Conductivity: The high thermal conductivity allows the element to transfer heat effectively.

- Mechanical Durability: With a high modulus of elasticity, the U Type SiC Heating Element can withstand high mechanical stress.

- Oxidation Resistance: The product maintains stability and performance in environments exposed to oxygen at high temperatures.

|

|

Product Functions

- Efficient Heat Transfer: The U shape of the SiC heating element maximizes the heat transfer area, leading to reduced energy consumption and lower operational costs.

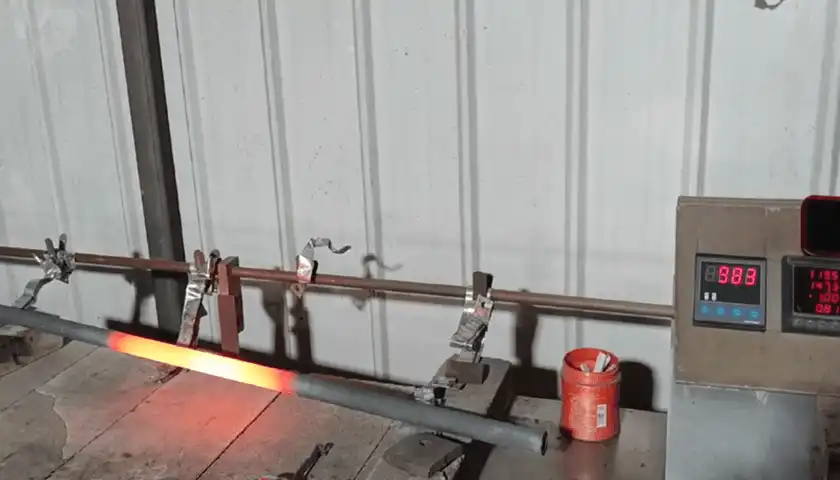

- High-Temperature Stability: Capable of operating at temperatures up to 1600°C, the element ensures consistent heating performance across various industrial applications.

- Durability in Harsh Environments: The element’s ability to resist oxidation and corrosion makes it suitable for use in furnaces, kilns, and reactors exposed to harsh atmospheres.

- Customizable for Different Industrial Applications: With a wide range of sizes and resistance options, the U Type SiC Heating Element can be tailored to meet the specific needs of any industrial process.

Product Applications

The versatility of the U Type SiC Heating Element makes it indispensable across various industries:

- Metallurgy: Used for heat treatment processes, such as annealing, sintering, and hardening of metals.

- Ceramics: Essential in kiln operations, the element provides uniform heating for the production of ceramic goods.

- Glass Manufacturing: Utilized in glass melting furnaces, where consistent high temperatures are critical.

- Chemical Processing: Suitable for reactors and other high-temperature equipment in the chemical industry.

|

|

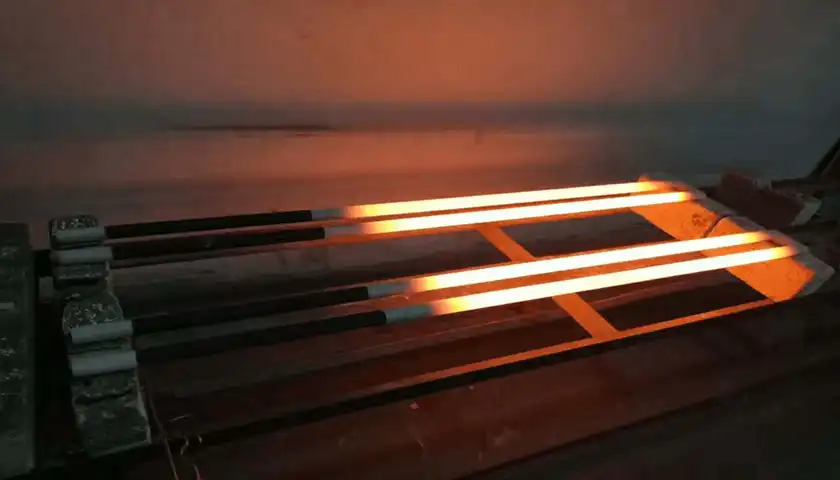

Product Process and Production Flow

The production of U Type SiC Heating Elements at Shaanxi Peakrise Metal Co., Ltd. involves advanced manufacturing techniques:

- Material Preparation: High-purity silicon carbide is sourced and processed to ensure uniformity in the final product.

- Forming: The SiC material is shaped into the U Type design, which maximizes heat transfer efficiency.

- Sintering: The elements are subjected to intermediate frequency sintering in specialized furnaces to enhance their strength and thermal properties.

- Finishing: Post-sintering, the elements are precision-machined to meet the specified dimensions and resistance values.

- Quality Control: Each batch undergoes rigorous testing to ensure compliance with international standards.

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts a state-of-the-art production facility equipped with cutting-edge technology. With over ten years of experience in the production of non-ferrous metals and heating elements, the company has earned a reputation for quality and innovation. The facility includes vacuum furnaces, CNC machines, and plasma welding stations, allowing us to produce high-quality SiC heating elements at scale.

Logistics and Packaging

- Wooden Crate Packaging: Suitable for large shipments and ensures safe transportation.

- Carton Packaging: Ideal for smaller orders, offering lightweight and cost-effective shipping.

- Foam-Filled Packaging: Provides additional protection against impact during transit.

- Waterproof and Moisture-Proof Packaging: Ensures product integrity, especially for overseas shipments.

- Custom Packaging: Tailored solutions based on customer needs, ensuring products arrive in perfect condition.

|

|

Logistics Options:

- Sea Freight: Cost-effective for large international orders.

- Air Freight: Fast delivery for urgent shipments.

- Land Transport: Efficient for domestic deliveries within China.

- Multimodal Transport: Combines sea, air, and land to optimize shipping time and cost.

- Courier Services: For smaller, urgent orders requiring quick delivery.

|

Why Choose Us?

- Extensive Industry Experience: Over a decade of experience in the production of high-performance heating elements and non-ferrous metals.

- Advanced Production Facilities: Equipped with modern manufacturing equipment to ensure product quality.

- Global Reach: Products exported to multiple countries, with a strong reputation for quality and reliability.

- Tailored Solutions: We offer customized SiC heating elements to meet the unique needs of each client.

- Commitment to Quality: All products are manufactured in compliance with international standards, and we maintain a robust quality control system.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. supports a wide range of OEM and ODM services. Whether you need a custom-sized SiC heating element or specific resistance values, our team will work closely with you to ensure your product meets your exact specifications. We offer flexible production capabilities and can accommodate both small and large orders.

|

|

FAQ

- What is the maximum operating temperature of the U Type SiC Heating Element?

- The maximum operating temperature is 1600°C, making it suitable for various high-temperature industrial processes.

- Can the element be customized?

- Yes, we provide customized solutions based on the client's specific requirements.

- How long is the lifespan of the heating element?

- The lifespan depends on the operating conditions, but our elements are designed for long-term use in harsh environments.

- What industries can use the U Type SiC Heating Element?

- The element is used in metallurgy, ceramics, glass manufacturing, and chemical processing industries.

- What packaging options are available?

- We offer wooden crates, cartons, foam-filled, waterproof, and custom packaging solutions.

Contact Us

Looking for a reliable supplier of U Type SiC Heating Elements? Contact Shaanxi Peakrise Metal Co., Ltd. today for high-quality products and tailored solutions to meet your industrial needs. Email us at info@peakrisemetal.com for inquiries or to place an order.

This product page is designed to be both informative and engaging, helping potential customers understand the full range of benefits that Shaanxi Peakrise Metal Co., Ltd. can provide.