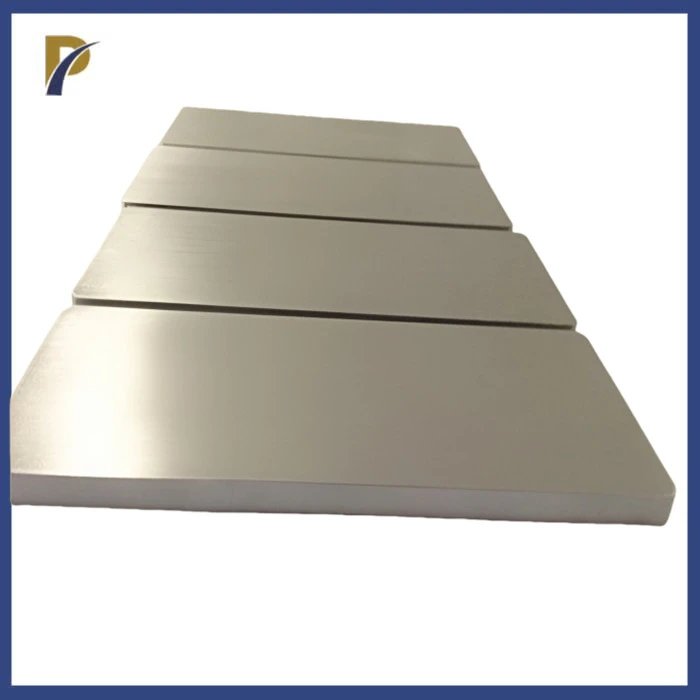

Corrosion-Resistant Zirconium Sheets

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Corrosion-Resistant Zirconium Sheets - Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

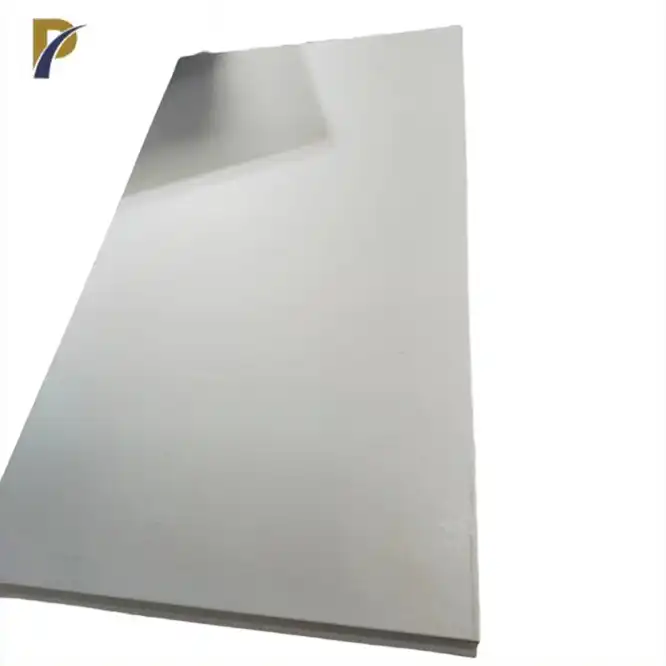

Corrosion-Resistant Zirconium Sheets are essential materials used in industries where high resistance to corrosive environments is critical. Zirconium is highly valued for its ability to withstand harsh chemicals, acids, and other reactive substances without degrading, making it a preferred choice in chemical processing, aerospace, and medical industries. At Shaanxi Peakrise Metal Co., Ltd., we are a leading supplier of high-quality Corrosion-Resistant Zirconium Sheets. Our extensive experience in the production of non-ferrous metals enables us to provide zirconium sheets with consistent quality and excellent performance.

Our zirconium sheets are made from premium raw materials, ensuring durability and corrosion resistance in challenging industrial environments. With a strong presence in the global market, we deliver tailored solutions that meet the highest standards, backed by a reliable supply chain and superior customer service. Whether you require standard or custom zirconium sheets, Shaanxi Peakrise Metal Co., Ltd. has the capability to fulfill your demands with precision and excellence.

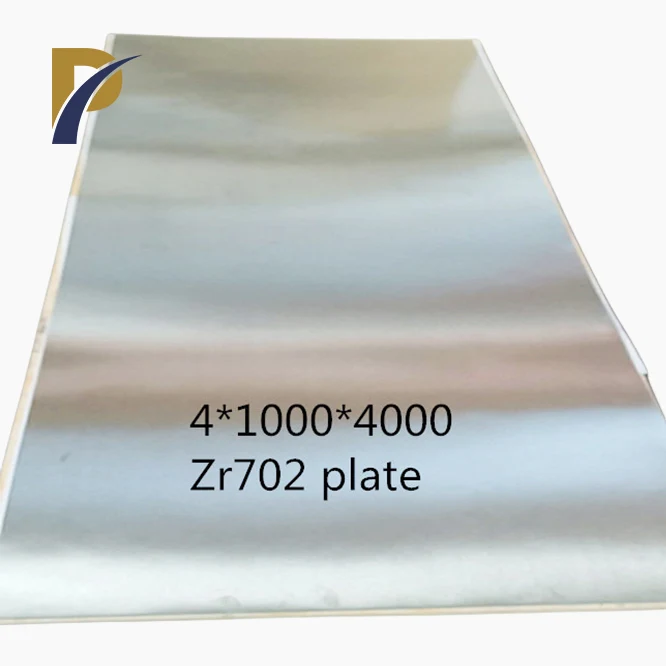

Product Specifications

Below is the detailed specification table for our Corrosion-Resistant Zirconium Sheets, covering various thicknesses, widths, and mechanical properties:

|

|

Physical and Chemical Properties

Zirconium sheets possess remarkable properties that make them suitable for various demanding applications:

- Density: 6.51 g/cm³

- Melting Point: 1855°C

- Boiling Point: 4409°C

- Thermal Conductivity: 22 W/m·K

- Corrosion Resistance: Excellent resistance to acids, alkalis, and seawater.

- Hardness: 240 HV

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

Product Functions

- Corrosion Resistance: Zirconium sheets exhibit exceptional resistance to corrosive environments, including acids, alkalis, and seawater, making them ideal for chemical processing and petrochemical applications.

- High Thermal Stability: With a high melting point and excellent thermal conductivity, zirconium sheets are well-suited for high-temperature environments, such as in heat exchangers and nuclear reactors.

- Durability: The material's strength and toughness ensure long service life, even under harsh operating conditions.

- Biocompatibility: Zirconium is non-toxic and biocompatible, making it a preferred material in medical and dental implants.

- Low Thermal Expansion: Its low thermal expansion reduces the risk of deformation under high temperatures, ensuring dimensional stability in various applications.

|

|

|

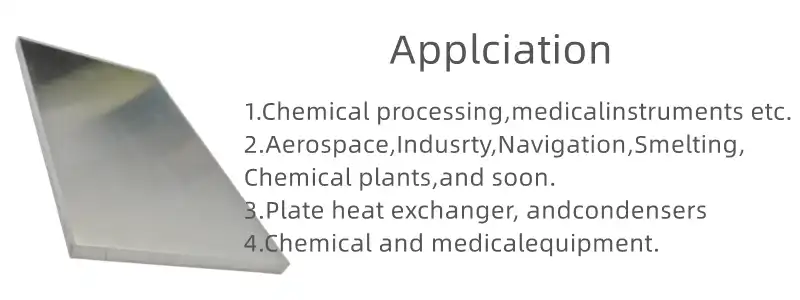

Product Applications

Corrosion-Resistant Zirconium Sheets find use in various industries due to their unique properties:

- Chemical Processing: Zirconium sheets are extensively used in equipment such as reactors, heat exchangers, and piping systems where exposure to corrosive chemicals is constant.

- Nuclear Industry: Zirconium’s low absorption cross-section for neutrons makes it an excellent material for nuclear reactor components, including cladding and fuel rods.

- Aerospace: The high strength-to-weight ratio and resistance to corrosion in harsh environments make zirconium sheets valuable for aerospace applications.

- Medical Industry: Zirconium’s biocompatibility makes it ideal for medical implants, surgical tools, and dental applications.

- Marine Engineering: The resistance to seawater corrosion ensures long-term performance in marine environments, used in seawater desalination plants and shipbuilding.

- Energy Sector: In the energy sector, zirconium sheets are used in high-performance batteries, hydrogen storage, and renewable energy technologies.

Manufacturing Process

The production of Corrosion-Resistant Zirconium Sheets at Shaanxi Peakrise Metal Co., Ltd. follows strict quality control protocols to ensure consistency and reliability:

- Raw Material Selection: High-purity zirconium ingots are carefully chosen based on industry standards.

- Melting: The zirconium ingots are melted in a vacuum arc furnace to ensure homogeneity.

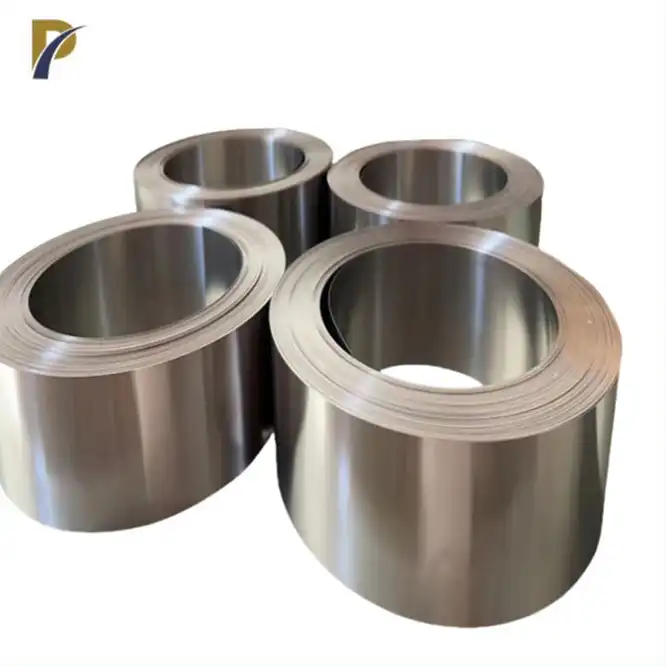

- Rolling: After melting, the zirconium is hot-rolled and then cold-rolled to achieve the desired thickness and surface finish.

- Annealing: The sheets undergo annealing to enhance ductility and mechanical strength.

- Surface Treatment: Surface polishing and cleaning are performed to meet customer-specific requirements.

- Quality Testing: Each batch of zirconium sheets is subjected to rigorous mechanical and chemical testing to ensure compliance with industry standards.

- Packaging: Sheets are carefully packaged to prevent contamination or damage during transportation.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is a leading manufacturer of non-ferrous metals, specializing in the production of tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel alloys. With advanced manufacturing equipment and over a decade of experience in the international market, we have established ourselves as a trusted supplier to industries worldwide. Our production facilities include state-of-the-art furnaces, rolling mills, and CNC machines, ensuring high precision and consistency in every product we deliver.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Company Main Products:

Zirconium crucible,zirconium rod,zirconium plate,zirconium target etc.

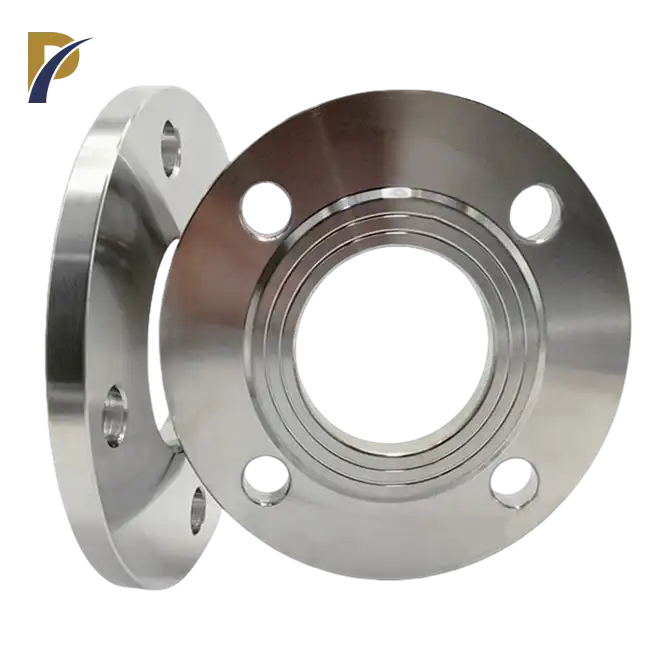

Titanium rod,sheet,tube,flange,screw,ring etc.

Molybdenum electrode,plate,rod,crucible,thread rod etc.

Tungsten wire,rod,sheet,crucible,electrode,tube etc.

Tantalum disc,foil,strip,rod,plate,tube etc.

Niobium target,rod,processing parts etc.

Packaging & Logistics

We offer customized packaging solutions to ensure the safe delivery of our products:

- Wooden Crates: Heavy-duty wooden crates for safe transportation.

- Carton Boxes: Lightweight and sturdy carton boxes for smaller quantities.

- Foam Padding: Foam padding to protect the sheets from impacts during shipping.

- Waterproof Packaging: Waterproof and moisture-resistant packaging for long-distance shipping.

- Custom Packaging: Tailored packaging options to meet client-specific requirements.

Logistics services include:

- Sea Freight: Cost-effective for large shipments.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Available for regional deliveries.

- Multimodal Shipping: Combining multiple transportation methods for optimal delivery efficiency.

- Express Delivery: Available for small, high-priority shipments.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Extensive Experience: With over a decade of expertise in non-ferrous metal production, we offer industry-leading products and solutions.

- Global Reach: Our products are exported to over 15 countries, including the United States, Germany, and South Korea.

- Advanced Technology: Equipped with cutting-edge machinery and advanced manufacturing processes, we ensure high-quality and precision in every product.

- Customization: We provide OEM and ODM services tailored to customer requirements, offering flexibility and innovation in product design.

- Quality Assurance: Each product undergoes strict quality control, from raw material selection to final testing.

- Comprehensive Services: We provide end-to-end solutions, including material research, product testing, and inventory management.

- Customer-Centric Approach: Our goal is to build long-term relationships with customers by offering exceptional service and support.

OEM/ODM Service

At Shaanxi Peakrise Metal Co., Ltd., we understand that each client has unique requirements. Our OEM/ODM services allow us to manufacture zirconium sheets in custom sizes, shapes, and specifications. Whether you need specific thicknesses or tailored surface treatments, we have the capabilities to deliver. We work closely with our clients to ensure that their specifications are met with precision and on time.

|

|

|

FAQs

-

What is the maximum thickness you can provide for zirconium sheets?

We can provide zirconium sheets with a thickness ranging from 0.5 mm to 20.0 mm. -

Can zirconium sheets be used in high-temperature environments?

Yes, zirconium has excellent thermal stability and can be used in high-temperature applications. -

What packaging options do you offer?

We offer wooden crates, carton boxes, foam padding, waterproof packaging, and custom packaging to suit your needs. -

Do you provide sample orders?

Yes, sample orders are available to help you evaluate our product quality. -

How long is the lead time for orders?

Lead time varies depending on order size and specifications, but typically ranges from 2 to 4 weeks.

Call to Action: Contact Us

Ready to explore high-performance Corrosion-Resistant Zirconium Sheets for your next project? Contact Shaanxi Peakrise Metal Co., Ltd. today to learn more about our products, discuss your specifications, or request a quote. Our team is here to help you find the perfect solution for your industry needs.

Email: info@peakrisemetal.com

We look forward to working with you!

YOU MAY LIKE

-

VIEW MOREtantalum foil 0.1mm

VIEW MOREtantalum foil 0.1mm -

VIEW MOREcustom tantalum rings

VIEW MOREcustom tantalum rings -

VIEW MOREtitanium metal plate

VIEW MOREtitanium metal plate -

VIEW MOREtitanium wire for jewelry

VIEW MOREtitanium wire for jewelry -

VIEW MOREpure titanium foil

VIEW MOREpure titanium foil -

VIEW MOREtitanium pipe fittings flange

VIEW MOREtitanium pipe fittings flange -

VIEW MORESingle thread silicon carbon rod heating element sic heater elements

VIEW MORESingle thread silicon carbon rod heating element sic heater elements -

VIEW MOREu shape sic heating element Silicon Carbon rod

VIEW MOREu shape sic heating element Silicon Carbon rod

_1742957394559.webp)

_1742957394563.webp)

_1742957394552.webp)