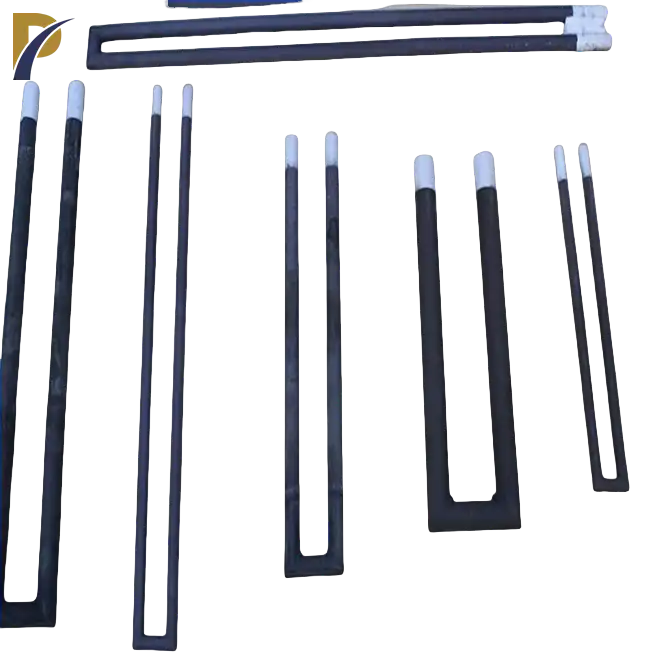

u shape sic heating element Silicon Carbon rod

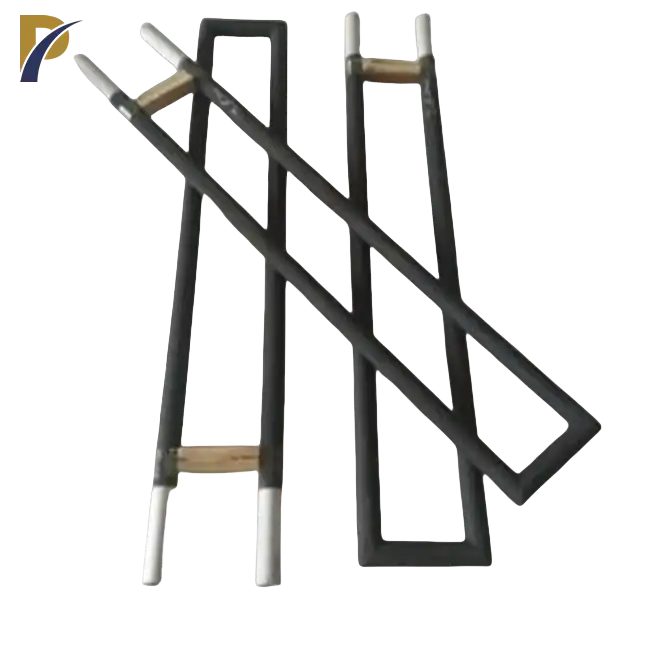

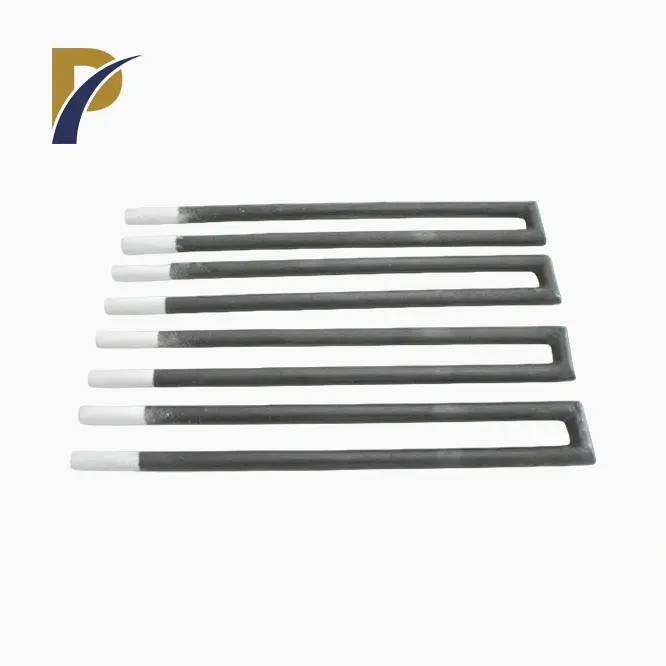

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

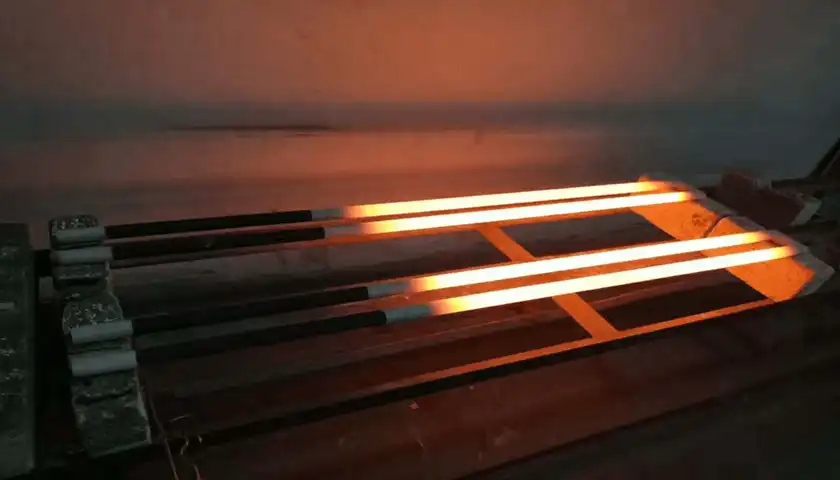

Product Introduction: U Shape SiC Heating Element

The U Shape SiC heating element is a critical component widely used in various high-temperature heating processes across multiple industries. Made from high-purity silicon carbide (SiC), these heating elements offer exceptional thermal performance, long lifespan, and high energy efficiency. Their unique U-shape design allows for uniform heat distribution and stable operation in demanding industrial environments, such as metallurgy, ceramics, and electronics manufacturing.

Shaanxi Peakrise Metal Co., Ltd. is a leading global supplier of U Shape SiC heating elements. With years of experience in producing high-quality heating solutions, we offer custom-made SiC heating elements that meet the specific needs of our international clients. We focus on providing durable, energy-efficient, and cost-effective solutions that enhance the productivity of our clients' industrial heating processes. Our extensive manufacturing capabilities allow us to produce SiC elements in various sizes and configurations to match specific industrial requirements.

Product Parameters:

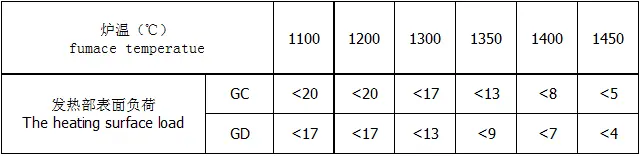

Element using temperature and surface load

Silicon carbide furnace design data for reference:

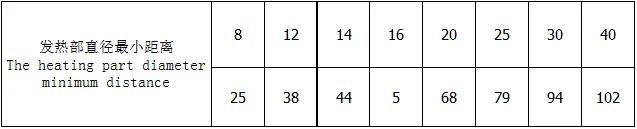

1.The two rod threading hole between the center distance is 3-4 times the diameter of the rod end.

2.The fumace wall and the material to be heated and elementbetween the distance of not less the data in the table below

3.The furnmace wall perforation should be used for 1.5 times the bardiameter,gap with asbestos line blocked strict.

Physical and Mechanical Properties:

The U Shape SiC heating element is made from recrystallized silicon carbide, which ensures high mechanical strength and chemical stability at elevated temperatures. This material also exhibits low thermal expansion, providing better resistance to thermal shock and rapid heating/cooling cycles. The elements are highly resistant to oxidation and corrosion in both air and controlled atmospheres.

- Density: 3.2 g/cm³

- Flexural Strength: 50 MPa at room temperature

- Thermal Conductivity: 120 W/m·K

|

|

Product Functions:

- High Thermal Efficiency: The U Shape SiC heating element provides a rapid rise in temperature, reducing energy consumption and shortening production cycles.

- Long Service Life: Engineered for durability, the elements maintain their performance over long periods even under harsh industrial conditions.

- Uniform Heat Distribution: The U-shape design ensures consistent heat output, which is essential for precision heating applications.

- Corrosion Resistance: Suitable for environments where exposure to aggressive chemicals, gases, or materials may occur.

- Wide Temperature Range: Capable of operating efficiently at temperatures up to 1,600°C.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Product Applications

- Metallurgical Furnaces: Used for annealing, sintering, and brazing of metals at high temperatures. SiC elements improve production efficiency and product quality.

- Ceramics Manufacturing: Ideal for firing and sintering ceramics, including technical ceramics and advanced ceramics used in electronics and aerospace.

- Glass Industry: Applied in glass tempering and annealing, ensuring a smooth and controlled heating process.

- Semiconductor Fabrication: Provides precision heating in processes like wafer fabrication, ensuring consistent product quality.

- Laboratory Equipment: Frequently used in high-temperature laboratory furnaces for testing materials and conducting research.

|

|

Product Process and Production Flow:

At Shaanxi Peakrise Metal Co., Ltd., we use state-of-the-art technology and equipment to manufacture U Shape SiC heating elements. The production process includes the following steps:

- Raw Material Selection: We use high-purity silicon carbide powders to ensure superior thermal and mechanical properties.

- Molding and Sintering: The powders are molded into the desired U shape and then sintered at high temperatures in our advanced vacuum furnaces.

- Machining: After sintering, each element is precisely machined to the required dimensions and inspected for quality.

- Coating and Assembly: For specific applications, additional protective coatings may be applied to enhance resistance to oxidation or chemical corrosion.

- Quality Control: Every batch undergoes rigorous testing for electrical resistance, temperature tolerance, and mechanical integrity to meet our high-quality standards.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a modern manufacturing facility equipped with advanced production lines and quality testing equipment. Our factory spans over 10,000 square meters, featuring:

- Intermediate Frequency Sintering Furnaces

- Vacuum Arc Melting Furnaces

- Laser Cutters and Plasma Welding Rooms

- CNC Machines, Milling Machines, and Grinders

Our commitment to continuous improvement ensures that we can meet the most demanding customer specifications.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

-

Packaging:

- Wooden crates for maximum protection

- Foam-filled packaging to prevent damage during transit

- Waterproof and moisture-resistant packaging for sensitive components

- Customized packaging to meet client needs, adhering to international standards

-

Logistics:

- Sea freight for bulk international shipments

- Air freight for urgent deliveries

- Land transportation for local distribution

- Multimodal transportation services to optimize delivery times and costs

- Courier services for smaller orders or samples

|

|

Why Choose Us?

- Extensive Experience: With over a decade of expertise in producing non-ferrous metals and heating elements, we deliver reliable and efficient solutions.

- High-Quality Standards: Our products undergo stringent testing and adhere to international quality standards.

- Customization: We offer OEM/ODM services, ensuring products tailored to specific industrial needs.

- Global Reach: Our products are exported worldwide, serving clients in over 20 countries, including the U.S., Germany, and South Korea.

- Comprehensive Support: From pre-sales consultation to after-sales service, we provide full support to our customers.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers custom manufacturing solutions for U Shape SiC heating elements. We support specific size and shape requirements, allowing customers to optimize their heating systems. Whether you need high-volume production or specialized small-batch orders, we have the flexibility and capacity to meet your demands.

FAQ

- What is the maximum temperature the U Shape SiC element can reach?

- Our elements can reach up to 1,600°C.

- How long does it take to heat up?

- Typically, it takes about 3-5 minutes to reach 1,000°C.

- Can I customize the shape and size of the heating element?

- Yes, we offer full customization options through our OEM/ODM services.

- What types of packaging are available?

- We offer wooden crates, foam-filled, and moisture-resistant packaging tailored to your needs.

- What is the average lifespan of the SiC heating element?

- Our elements last around 2,000 hours, depending on the operating conditions.

Contact Us

Are you looking for reliable, high-performance U Shape SiC heating elements? Shaanxi Peakrise Metal Co., Ltd. is ready to meet your needs. Our expertise, quality assurance, and global reach make us the ideal partner for your industrial heating solutions. Contact us today at info@peakrisemetal.com for more information or to place an order. We look forward to working with you!