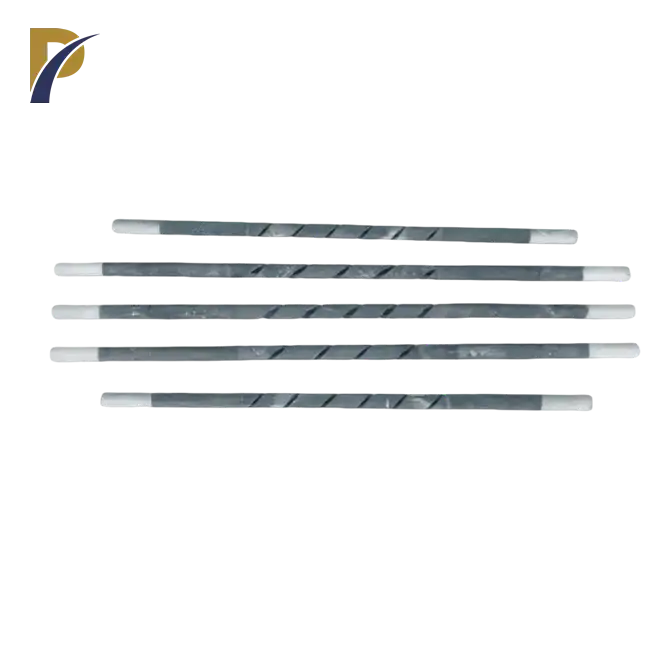

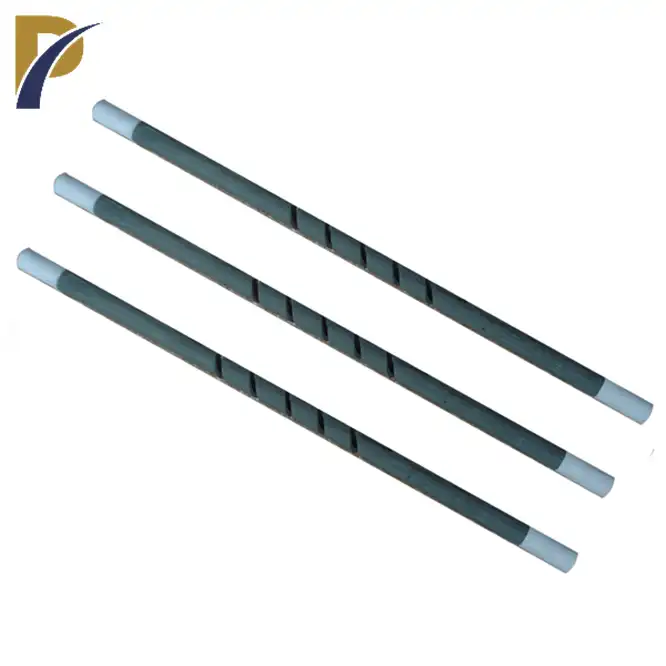

Single thread silicon carbon rod heating element sic heater elements

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

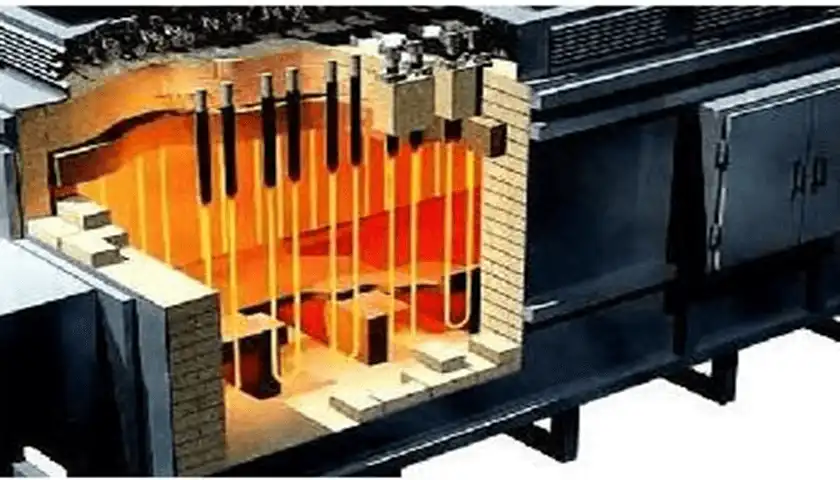

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction:

The heating part of the single-threaded silicon carbon rod is made of special materials, with a density of 2.8g/cm3, a maximum operating temperature of 1625°C, and a long service life. Both ends are connected.

Features:

1. The highest surface can reach 1625℃

2. Durable and long working life

3. High strength and good shock resistance

4. No noise and air pollution, environmentally friendly

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of single spiral SiC heater elements, offering reliable and high-quality products tailored to meet the specific needs of global industrial customers. With years of experience in manufacturing non-ferrous metals and specialty materials, we ensure that our heater elements are crafted to provide long-lasting performance, energy efficiency, and minimal maintenance. Our commitment to quality, coupled with our extensive R&D capabilities, enables us to provide cutting-edge solutions for industries requiring precise thermal management.

Product Parameters Table:

| Element Diameter(mm) | Nominal loading ( at 1050℃ ) | |||

| Hot Zone | Cold Zone | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 14.0 | 0.02567 | 6.59 | 0.00450 | 0.30 |

| 16.0 | 0.02094 | 7.54 | 0.00387 | 0.50 |

| 18.0 | 0.01948 | 8.43 | 0.00312 | 0.55 |

| 20.0 | 0.01677 | 9.42 | 0.00291 | 0.60 |

| 25.0 | 0.01365 | 11.78 | 0.00174 | 0.93 |

| 30.0 | 0.01020 | 14.13 | 0.00120 | 0.95 |

| 35.0 | 0.00669 | 16.49 | 0.00096 | 0.98 |

| 40.0 | 0.00624 | 18.84 | 0.00072 | 1.00 |

| 45.0 | 0.00546 | 20.91 | 0.00066 | 1.0 |

|

|

Physical and Mechanical Properties:

- High Thermal Conductivity: Silicon carbide heater elements provide exceptional thermal conductivity, allowing them to reach and maintain high temperatures efficiently.

- Durability: The robust material composition makes these elements resistant to oxidation, corrosion, and thermal shock, ensuring long service life even in harsh environments.

- Mechanical Strength: SiC heater elements exhibit excellent mechanical strength, allowing them to withstand mechanical stress during operation.

- Low Electrical Resistance: These elements are designed with low electrical resistance, allowing for efficient power consumption and minimized energy loss.

|

|

|

Product Functions:

- Efficient Heat Generation: The primary function of single spiral SiC heater elements is to generate high-temperature heat efficiently. The spiral design maximizes the heat output while minimizing energy consumption.

- Uniform Heat Distribution: The spiral structure ensures uniform heat distribution across the heating zone, making it ideal for processes that require consistent thermal application.

- Energy Efficiency: Due to their low resistance and high thermal conductivity, SiC heater elements reduce energy consumption, making them an eco-friendly option for industrial applications.

- Thermal Stability: These heater elements maintain stable performance over extended periods, even when subjected to high operational temperatures, reducing the need for frequent replacements or maintenance.

Product Applications:

- Ceramics Industry: Single spiral SiC heater elements are commonly used in kilns for firing ceramics due to their ability to withstand and maintain high temperatures required for glazing and baking.

- Metallurgy: In the metallurgical industry, these elements are used in furnaces for heat treatment, sintering, and metal refining processes, ensuring uniform and consistent heating.

- Chemical Processing: The corrosion resistance of SiC makes it ideal for chemical reactors and furnaces in the chemical industry, where harsh environments and high temperatures are involved.

- Glass Production: The high-temperature stability and uniform heat distribution make these elements perfect for glass melting and processing applications.

- Laboratory Equipment: SiC heater elements are used in laboratory furnaces and test equipment for material testing and analysis, ensuring precise temperature control.

|

|

Product Process and Production Flow:

The production of single spiral SiC heater elements at Shaanxi Peakrise Metal Co., Ltd. involves a highly controlled process to ensure the highest quality standards. Our manufacturing process includes the following steps:

- Material Selection: We use premium-grade silicon carbide and other raw materials, ensuring durability and high performance.

- Precision Molding: The elements are molded into a spiral shape using state-of-the-art equipment, ensuring uniformity and consistency across all products.

- High-Temperature Sintering: The elements undergo sintering at extremely high temperatures, which enhances their structural integrity and thermal properties.

- Quality Inspection: Each product undergoes rigorous testing and inspection to ensure it meets our stringent quality standards before being delivered to customers.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with advanced manufacturing facilities, including vacuum furnaces, CNC machines, and plasma welding equipment. Our factory is committed to producing high-quality non-ferrous metal products, with a focus on continuous innovation and improvement. With a dedicated team of engineers and technicians, we ensure that all products are manufactured according to ISO 9001 standards and are subjected to comprehensive quality control checks.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We take utmost care in packaging and delivering our products to ensure they reach our customers in perfect condition. Our packaging options include:

- Wooden crates

- Foam-filled boxes

- Waterproof and moisture-proof packaging

- Custom packaging solutions as per client requirements

- Packaging that meets international shipping standards

We offer the following logistics options to ensure timely delivery:

- Sea freight

- Air freight

- Land transportation

- Multimodal transport

- Courier services

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Experience: Shaanxi Peakrise Metal Co., Ltd. has over a decade of experience in producing and supplying non-ferrous metals globally.

- Comprehensive Product Range: We offer a wide range of products, including SiC heater elements, tungsten-copper alloys, tantalum alloys, and more.

- Advanced Equipment: Our factory is equipped with cutting-edge machinery, allowing us to deliver precise and high-quality products.

- Customer-Centric Approach: We prioritize our customers' needs and offer personalized solutions, including OEM/ODM services.

- Global Reach: Our products are exported to over 10 countries, including the USA, South Korea, and Germany.

|

OEM Services

We provide extensive OEM and ODM services, allowing our clients to customize the size, shape, and technical specifications of their SiC heater elements to meet their unique operational needs. Our experienced R&D team works closely with clients to develop innovative solutions that enhance their product performance.

FAQ

-

What is the maximum operating temperature of SiC heater elements?

- Our single spiral SiC heater elements can operate at temperatures up to 1600°C, making them ideal for high-temperature applications.

-

How long do SiC heater elements last?

- With proper maintenance, SiC heater elements can last several years, even under extreme operational conditions.

-

Can you customize the size of the heater elements?

- Yes, we offer custom sizes and shapes as per your requirements. Contact our team for more details.

-

What industries commonly use SiC heater elements?

- They are used in industries such as ceramics, metallurgy, glass manufacturing, and chemical processing.

-

Do you offer international shipping?

- Yes, we provide international shipping through multiple logistics options, including sea and air freight.

Contact Us

We invite global purchasers and industrial professionals to partner with Shaanxi Peakrise Metal Co., Ltd. for high-quality single spiral SiC heater elements. For inquiries and further information, feel free to contact us at info@peakrisemetal.com. Our team is ready to assist you with customized solutions to meet your heating element needs.