Zirconium Precision Cut Rods

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Precision Cut Rods - High-Quality Solutions from Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Zirconium Precision Cut Rods are crucial components in industries that demand high performance and resilience in extreme conditions. Known for their exceptional corrosion resistance, high melting point, and remarkable strength, these rods are ideal for use in demanding environments such as chemical processing, nuclear power, aerospace, and medical industries. Zirconium offers unparalleled resistance to acids, bases, and seawater, making it a preferred choice in corrosive environments where other materials fail.

At Shaanxi Peakrise Metal Co., Ltd., we specialize in the production of high-quality Zirconium Precision Cut Rods, tailored to meet the stringent requirements of global industries. With over a decade of experience, we have established ourselves as a reliable supplier of zirconium and other non-ferrous metals, offering precision manufacturing and excellent quality control at every stage of production. Our cutting-edge production facilities and experienced team ensure that every rod meets or exceeds industry standards, providing durability, precision, and long-term performance.

Product Specifications

| Property | Value |

|---|---|

| Material Grade | Zr702, Zr705 |

| Diameter Range | 3.0 mm - 100 mm |

| Length | 100 mm - 6000 mm |

| Tolerance (Diameter) | ±0.01 mm |

| Surface Finish | Polished, Ground |

| Density | 6.52 g/cm³ |

| Melting Point | 1855°C |

| Tensile Strength | 330 MPa - 600 MPa |

| Hardness (HV) | 120 - 160 HV |

| Standard | ASTM B550, ASTM B551 |

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

|

|

|

Product Features

- High Corrosion Resistance: Zirconium rods are extremely resistant to corrosion in a wide range of aggressive environments, including strong acids and seawater.

- High Strength-to-Weight Ratio: Despite being lightweight, zirconium rods provide excellent strength, making them ideal for structural applications in the aerospace and nuclear industries.

- Heat Resistance: With a melting point of 1855°C, zirconium rods can withstand extreme temperatures without deformation or loss of integrity.

- Biocompatibility: Zirconium is non-toxic and biocompatible, which makes it a popular choice for medical implants and devices.

- Oxidation Resistance: When exposed to air, zirconium forms a stable oxide layer that protects it from further corrosion, ensuring longevity in service.

Applications of Zirconium Precision Cut Rods

- Chemical Processing: The exceptional corrosion resistance of zirconium makes it ideal for manufacturing equipment used in chemical processing plants, such as reactors, heat exchangers, and piping systems.

- Nuclear Industry: Zirconium is widely used in nuclear reactors due to its low neutron absorption cross-section, making it suitable for cladding fuel rods.

- Aerospace: With its high strength-to-weight ratio and resistance to extreme temperatures, zirconium rods are used in the aerospace industry for structural components.

- Medical Devices: Due to its biocompatibility, zirconium is used in surgical instruments and implants, providing durability and resistance to bodily fluids.

- Marine Applications: The corrosion resistance of zirconium rods in saltwater environments makes them an excellent choice for marine applications, such as shipbuilding and offshore equipment.

|

|

Manufacturing Process

- Material Selection: The process begins with selecting high-purity zirconium ingots that meet international standards.

- Melting: The ingots are melted using advanced vacuum arc or electron beam melting techniques to ensure purity and uniformity.

- Forming: The molten zirconium is then shaped into rods through precision rolling or extrusion processes.

- Cutting: The rods are precision-cut to specified lengths using laser cutting technology, ensuring smooth and accurate dimensions.

- Surface Treatment: Polishing and grinding are performed to achieve the desired surface finish, providing corrosion resistance and a smooth, defect-free surface.

- Quality Control: Every rod undergoes rigorous testing, including dimensional checks, tensile strength testing, and surface inspection, to guarantee compliance with ASTM standards.

Why Choose Shaanxi Peakrise Metal Co., Ltd.?

- Expertise: With over 10 years of experience in the non-ferrous metals industry, we bring a wealth of knowledge and expertise to every project.

- State-of-the-art Production Facilities: Our advanced equipment, including vacuum arc melting furnaces, CNC machines, and laser cutters, ensures precision and high-quality products.

- Customization: We offer comprehensive OEM services, allowing us to produce zirconium rods to your exact specifications.

- Global Reach: Our products are trusted by clients worldwide, with exports to markets in the United States, Germany, Australia, and more.

- Strict Quality Control: We follow stringent quality control procedures, ensuring that each product meets the highest standards before it leaves our facility.

style="font-size:28px">Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

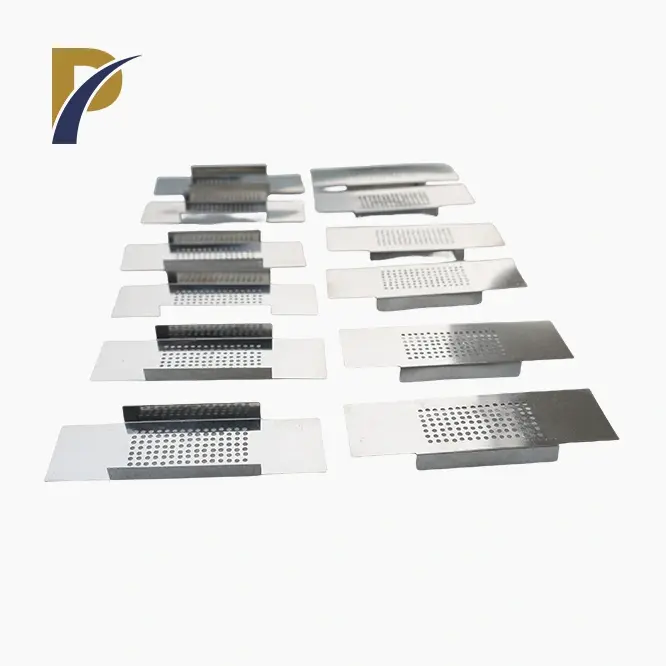

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer flexible OEM/ODM services tailored to meet your specific needs. Whether you require custom sizes, shapes, or surface finishes, we have the capability to deliver. Our dedicated team works closely with clients to ensure that all specifications are met, providing full support throughout the design, manufacturing, and testing process.

|

|

|

|

|

|

|

|

|

Packaging

- Wooden Crate Packaging: Ensures the safe transportation of large shipments.

- Cardboard Boxes: Lightweight and sturdy for smaller orders.

- Foam Inserts: Provides cushioning to prevent damage during transit.

- Waterproof Packaging: Protects against moisture and humidity during shipping.

- Custom Packaging: We offer bespoke packaging solutions to meet specific client requirements.

- International Standard Compliance: All packaging meets international standards for safe and secure shipping.

Logistics

- Sea Freight: Ideal for bulk orders, offering cost-effective shipping for large volumes.

- Air Freight: Faster shipping method for urgent orders or lightweight products.

- Land Transportation: Reliable overland delivery for regional markets.

- Multimodal Transport: Combines sea, air, and land shipping for flexible logistics solutions.

- Courier Services: Fast and efficient delivery for smaller, high-priority orders.

FAQs

-

What grades of zirconium do you offer?

- We offer zirconium rods in Zr702 and Zr705 grades, both of which are corrosion-resistant and meet ASTM standards.

-

Can you provide custom sizes for zirconium rods?

- Yes, we offer a wide range of customization options to meet specific client requirements, including custom diameters, lengths, and surface finishes.

-

What industries use zirconium rods?

- Zirconium rods are widely used in the chemical, nuclear, aerospace, medical, and marine industries due to their corrosion resistance and high-temperature performance.

-

What is the lead time for orders?

- Lead times vary depending on the order size and customization requirements. Typically, we deliver within 4-6 weeks.

-

Do you offer samples for testing?

- Yes, we can provide samples upon request to help you assess the quality and suitability of our zirconium rods for your application.

Related Products

| Zirconium crucible | zirconium ring for black wedding ring | SiC heating element for Lab furnace | 0.05mm zirconum foil |

Contact Us

Ready to partner with a leading supplier of zirconium precision cut rods? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss your project requirements. We are committed to providing high-quality products and exceptional customer service. Reach us at info@peakrisemetal.com and let’s take your business to new heights.

_1742884662728.webp)

_1742884662739.webp)

_1742884662732.webp)

_1742884662735.webp)