ERZr-4 Zr705 99.0% Purity Zirconium Alloy Welding Wire

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

ERZr-4 Zr705 99.0% Purity Zirconium Alloy Welding Wire

Product Introduction

At Shaanxi Peakrise Metal Co., Ltd, we take pride in being a leading supplier of ERZr-4 Zr705 99.0% Purity Zirconium Alloy Welding Wire. Our zirconium wire is specially designed for various applications in the valve industry, ensuring durability, reliability, and exceptional performance. Zirconium is renowned for its outstanding resistance to corrosion and high temperatures, making it an ideal choice for valve components used in harsh environments.

Zirconium wire's unique properties, including its excellent ductility and high melting point, allow it to withstand extreme operational conditions, ensuring a long service life for valve systems. Our extensive experience in producing non-ferrous metals, combined with advanced manufacturing processes, guarantees that our zirconium wire meets the highest industry standards.

As a well-established enterprise specializing in tungsten, molybdenum, tantalum, niobium, titanium, and zirconium production, Shaanxi Peakrise Metal Co., Ltd has cultivated a reputation for delivering top-quality products. We have been serving international markets since 2010, providing premium non-ferrous metal solutions to customers in Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran, and beyond.

Our zirconium wire is meticulously crafted to ensure optimal performance in various valve applications, such as oil and gas, petrochemical, and power generation industries. With our commitment to quality and customer satisfaction, we strive to be your trusted partner in sourcing high-performance zirconium wire for valve components.

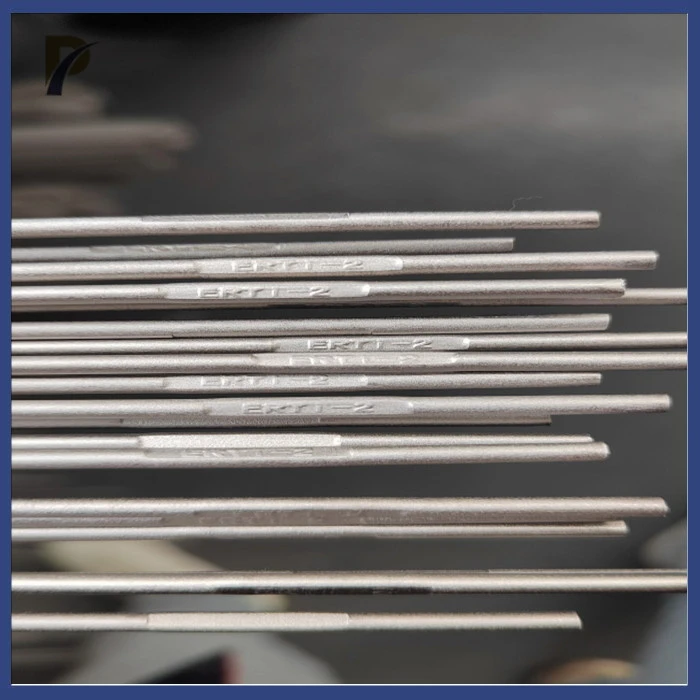

Product Specifications

| Name | Zirconium alloy welding wire |  |

| Grade | ERZr-4 Zr60705 | |

| Diameter | φ1.0 φ1.6 φ2.4 φ2.0 φ3.2 φ4.0 | |

| Density | 6.51g/cm3 | |

| Purity | >95.5% | |

| Surface | pickling surface | |

| Standard | AWS. A5.24 |

Physical and Chemical Properties

| Content | Zr+Hf | Hf | Fe+Cr | Nb | O | H | N | C | Each impurity | Total impurity |

| Standard value | ≥95.5 | ≤4.5 | 0.2 | 2.0-3.0 | 0.11-0.16 | ≤0.05 | ≤0.015 | ≤0.03 | ≤0.05 | ≤0.2 |

| Typical value | 97.6 | 0.91 | 0.18 | 2.2 | 0.12 | 0.002 | 0.004 | 0.013 | 0.02 | 0.002 |

Product Functions

-

Corrosion Resistance: Zirconium welding wire exhibits exceptional resistance to corrosion, particularly in acidic and alkaline environments. This makes it suitable for valve components exposed to aggressive chemicals.

-

High Temperature Stability: With a melting point of 1852 °C, zirconium welding wire remains stable at high temperatures, ensuring the integrity of valve components even in extreme conditions.

-

Ductility: The high ductility of zirconium welding wire allows for easy forming and shaping during manufacturing, ensuring precise fit and function in valve applications.

-

Lightweight: Zirconium is lighter than many other metals, reducing the overall weight of valve assemblies without compromising strength.

-

Low Thermal Expansion: Zirconium's low thermal expansion rate minimizes dimensional changes with temperature fluctuations, ensuring consistent valve performance.

|

|

Product Applications

Zr705 Zirconium welding wire has excellent corrosion resistance. It has very good corrosion resistance to most organic acids, inorganic acids, strong bases and some molten salts. Hydrochloric acid, nitric acid and organic acids near 100°C have no effect on zirconium. The corrosion resistance of zirconium in alkali is better than that of titanium, tantalum, niobium and stainless steel, and it has good heat resistance and processability. It is mainly used in pressure vessels, petrochemical industry, aerospace, marine engineering, hydrogenation reactors and other fields.

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd, we utilize advanced manufacturing techniques to produce high-quality zirconium wire. The production process includes:

-

Material Selection: We source premium-grade zirconium to ensure the highest quality of our wire.

-

Melting: The zirconium is melted using a vacuum arc melting furnace, eliminating impurities.

-

Forming: The melted zirconium is then shaped into wire using specialized wire drawing machines, allowing for precise control over diameter and properties.

-

Annealing: The wire undergoes a vacuum annealing process to enhance its ductility and eliminate internal stresses.

-

Quality Control: Each batch of zirconium wire is rigorously tested for tensile strength, corrosion resistance, and dimensional accuracy to meet industry standards.

Company Introduction

Shaanxi Peakrise Metal Co., Ltd is a reputable manufacturer of non-ferrous metals, including tungsten, molybdenum, tantalum, niobium, titanium, zirconium, and nickel. Established in 2010, our company has focused on the foreign trade market, providing high-quality metal products to international customers.

Our extensive product range includes over 100 varieties, with a strong emphasis on quality and customer service. We have invested in advanced production equipment, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, laser cutters, and CNC machinery, to enhance our manufacturing capabilities.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

-

Wooden Crate Packaging: Durable wooden crates are used for shipping to protect the zirconium wire during transit.

-

Carton Packaging: For smaller orders, we utilize sturdy cartons to ensure the product's safety.

-

Foam Filling: Foam inserts are used to secure the wire and prevent movement within the packaging.

-

Waterproof Packaging: All products are packaged to be waterproof and moisture-proof, ensuring quality upon arrival.

-

Custom Packaging: We offer customized packaging solutions to meet specific customer requirements.

Shipping Options

-

Sea Freight: Ideal for large shipments, providing cost-effective transportation over long distances.

-

Air Freight: Fast and reliable service for urgent orders, ensuring quick delivery.

-

Land Transport: Efficient for regional deliveries, utilizing trucks for timely service.

-

Multimodal Transport: Combining various transport methods for optimal delivery efficiency.

-

Express Services: For immediate needs, we partner with express services for swift delivery.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

-

Experienced Manufacturer: With over a decade of experience, we understand the complexities of the non-ferrous metal market and have established a solid reputation.

-

Quality Assurance: Our rigorous quality control processes ensure that every product meets international standards, providing peace of mind to our customers.

-

Diverse Product Range: We offer a comprehensive selection of non-ferrous metal products, making us a one-stop shop for all your metal needs.

-

Strong Export Network: Our products are exported to numerous countries, establishing long-term relationships with clients globally.

-

Commitment to Innovation: We continually invest in new technologies and processes to improve our products and services.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. is proud to offer OEM/ODM services, allowing clients to customize zirconium wire specifications according to their unique requirements. Whether you need specific dimensions, material compositions, or packaging options, we are here to support your needs.

|

|

Frequently Asked Questions (FAQ)

-

What is the minimum order quantity for zirconium welding wire?

- Our minimum order quantity is 100 meters, but we can accommodate smaller orders upon request.

-

What is the lead time for orders?

- Standard lead time is 4-6 weeks, depending on the order size and customization requirements.

-

Do you provide certificates for your products?

- Yes, we provide material certificates and test reports for all our products.

-

Can I get a sample before placing a bulk order?

- Yes, we offer samples for evaluation. Please contact us for more details.

-

What are your payment terms?

- We accept various payment methods, including T/T, L/C, and PayPal, depending on the order size.

Call to Action (CTA)

If you're looking for a reliable supplier of ERZr-4 Zr705 99.0% Purity Zirconium Alloy Welding Wire , look no further than Shaanxi Peakrise Metal Co., Ltd. With our commitment to quality, customer satisfaction, and competitive pricing, we are your ideal partner in sourcing high-performance zirconium welding wire.

Contact us today at info@peakrisemetal.com to discuss your requirements and get a quote. We look forward to collaborating with you to meet your metal needs!