Zirconium Sheet for Heat Exchangers

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Sheet for Heat Exchangers: Your Best Choice for High Efficiency and Durability

Product Introduction

Zirconium sheets are critical components in the heat exchanger industry due to their exceptional corrosion resistance, high temperature tolerance, and overall durability. At Shaanxi Peakrise Metal Co., Ltd., we take pride in being a trusted supplier of high-quality zirconium sheets specifically designed for heat exchanger applications. Our zirconium sheets are widely recognized in the market for their performance, reliability, and longevity. Zirconium, a transition metal known for its low thermal neutron absorption cross-section and exceptional corrosion resistance, is the ideal choice for heat exchangers in industries such as chemical processing, nuclear power generation, and oil refining.

Our zirconium sheets are meticulously manufactured using state-of-the-art equipment to meet stringent industry standards. They are highly resistant to corrosion from acids, alkalis, and seawater, making them perfect for harsh environments. As a leader in the production of zirconium materials, Shaanxi Peakrise Metal Co., Ltd. offers zirconium sheets in various thicknesses and dimensions, ensuring we meet your specific heat exchanger requirements. We have extensive experience in international trade, exporting to numerous countries, including Taiwan, Ukraine, South Korea, the United States, and Germany.

Our expertise in producing non-ferrous metals, combined with our commitment to delivering premium-quality products, ensures that we can meet the exact needs of customers worldwide. Whether you require zirconium sheets for new heat exchangers or replacement parts for existing systems, we have the solution.

Product Specifications

| Name | Zirconium Sheet for Heat Exchangers |

| Material | Zirconium & Zirconium alloy |

| Grade | Zr702,Zr704,Zr705,RO60001,RO60901,RO60804 |

| Purity | >99.7% |

| Density | 6.51g/cm3 |

| Standard | ASTM B551,ASTM B352 |

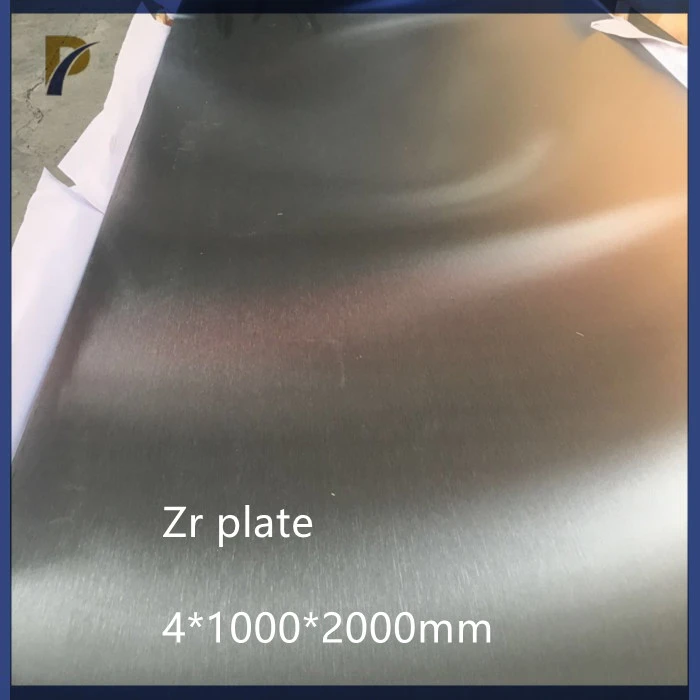

| Size | 0.3-50mm*1000*6000mm |

| Shape | Plate/sheet |

| Surface | Polished |

| MOQ | 1kg |

| Custom | Yes, we can OEM,ODM |

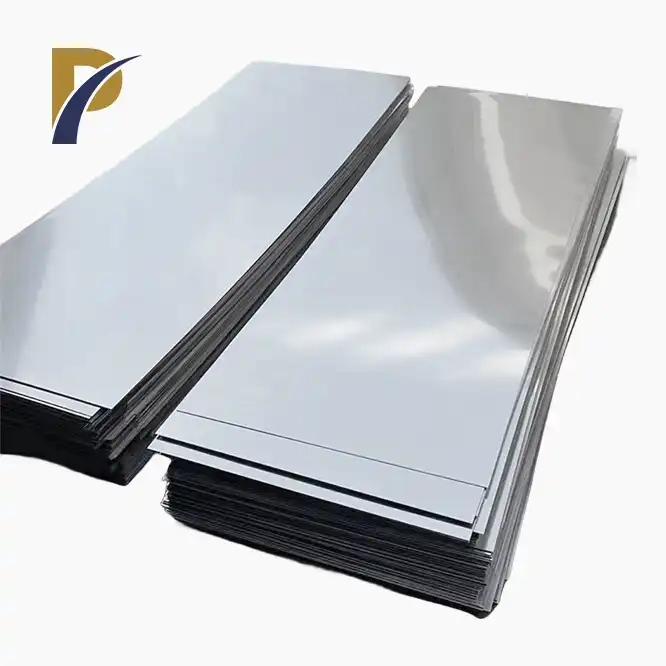

| Package | Plywood case |

| Country of origin | Shaanxi,China |

| Application | 1.Chemical processing,medicalinstruments etc. 2.Aerospace,Indusrty,Navigation,Smelting,Chemical plants,and soon. 3.Plate heat exchanger, andcondensers 4.Chemical and medicalequipment. |

|

|

|

Physical and Chemical Properties

Zirconium sheets have unique physical and chemical properties that make them essential for heat exchangers:

- Density: 6.52 g/cm³

- Melting Point: 1855°C

- Thermal Conductivity: 22 W/m·K

- Coefficient of Thermal Expansion: 5.7 x 10⁻⁶/K

- Corrosion Resistance: Superior against hydrochloric acid, sulfuric acid, and organic acids.

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

Product Features

- Superior Corrosion Resistance: Zirconium's natural resistance to acidic and corrosive environments makes it perfect for long-lasting use in heat exchangers, especially in chemical and petrochemical applications.

- High Temperature Stability: Zirconium sheets can withstand extreme temperatures, maintaining their structural integrity even in challenging conditions, making them ideal for high-heat environments.

- Excellent Mechanical Properties: With a combination of high tensile strength and ductility, zirconium sheets are not only durable but also flexible, making them easy to work with in various manufacturing processes.

- Low Thermal Neutron Absorption: Zirconium’s low absorption of thermal neutrons makes it indispensable in nuclear power generation, where heat exchangers operate in environments exposed to radiation.

- Customizable Thickness and Dimensions: Our zirconium sheets are available in a wide range of thicknesses, and we offer customized dimensions to meet the specific requirements of your heat exchangers.

Product Applications

Zirconium sheets are commonly used in heat exchangers across a variety of industries due to their outstanding properties:

- Chemical Processing: The corrosion resistance of zirconium sheets against strong acids like hydrochloric acid and sulfuric acid makes them ideal for heat exchangers in chemical plants.

- Nuclear Power Plants: In the nuclear industry, zirconium's low neutron absorption is essential in heat exchangers that are exposed to radiation, ensuring efficiency and safety.

- Oil Refining: The heat exchangers used in oil refining benefit from zirconium’s resistance to high temperatures and corrosive environments, extending the lifespan of the equipment.

- Desalination Plants: In seawater environments, zirconium sheets prevent the corrosion that typically occurs with other metals, making them perfect for use in heat exchangers in desalination facilities.

- Aerospace: With its ability to withstand high temperatures and corrosion, zirconium is increasingly being used in aerospace heat exchangers to improve efficiency and durability.

Manufacturing Process and Production Flow

Our zirconium sheets are produced using the latest technology and strict quality control processes to ensure top-notch performance. The production flow includes the following steps:

- Raw Material Selection: We source high-purity zirconium ingots to ensure that the sheets we produce meet international quality standards.

- Melting: The ingots are melted in a vacuum arc furnace to remove impurities and produce a homogeneous material.

- Rolling and Annealing: The melted zirconium is rolled into sheets of the desired thickness, followed by annealing to achieve the required mechanical properties.

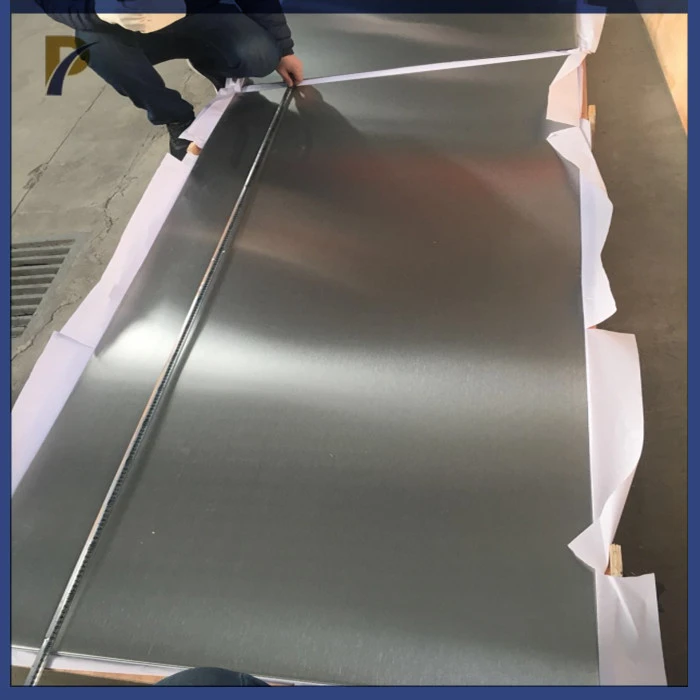

- Surface Treatment: The sheets undergo surface treatment to enhance their resistance to corrosion and ensure a smooth finish.

- Quality Inspection: Each zirconium sheet is subjected to rigorous testing, including tensile strength, yield strength, and corrosion resistance, to ensure compliance with industry standards.

- Packaging: Once approved, the zirconium sheets are carefully packed to prevent damage during transit.

Why Choose Shaanxi Peakrise Metal Co., Ltd?

- Expertise in Non-Ferrous Metals: With over a decade of experience in the production and export of non-ferrous metals, we are experts in meeting the needs of global customers.

- High-Quality Products: Our zirconium sheets are produced to the highest industry standards, ensuring long-lasting performance in demanding environments.

- Customized Solutions: We offer OEM/ODM services, allowing us to tailor products to meet your specific requirements.

- Global Reach: Our products are exported to numerous countries, and we have established long-term relationships with customers worldwide.

- Comprehensive Services: From product development to manufacturing and delivery, we provide a full range of services to ensure your satisfaction.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we understand that each customer has unique requirements. That’s why we offer customized OEM/ODM services for zirconium sheets. Whether you need specific dimensions, thickness, or surface treatments, our experienced team is ready to work with you to create a product that fits your exact needs. We ensure fast production times and high-quality standards.

|

|

|

FAQ

-

What are the main advantages of using zirconium sheets in heat exchangers?

- Zirconium sheets offer exceptional corrosion resistance and high temperature stability, making them ideal for demanding environments.

-

Can I order custom-sized zirconium sheets?

- Yes, we provide custom dimensions and thicknesses to suit your specific heat exchanger requirements.

-

How long does the production process take?

- Production time varies based on order size and customization needs, but we strive to deliver within 4-6 weeks for standard orders.

-

What industries typically use zirconium sheets?

- Zirconium sheets are widely used in chemical processing, nuclear power generation, oil refining, desalination, and aerospace industries.

-

What is your minimum order quantity (MOQ)?

- Our MOQ is flexible, depending on the specific product and customization requirements. Contact us for more details.

Packaging

We take great care in ensuring that our zirconium sheets are securely packaged to prevent any damage during transit. We offer a variety of packaging options:

- Wooden Crates: For large quantities and heavy-duty protection.

- Cardboard Boxes: For smaller orders and lightweight shipments.

- Foam Padding: Added inside packages for cushioning and impact protection.

- Waterproof Wrapping: To prevent moisture damage during shipment.

- Custom Packaging: Available based on your specific needs and international shipping standards.

Logistics

We offer multiple logistics options to ensure your zirconium sheets arrive safely and on time:

- Sea Freight: Cost-effective for large, bulk orders.

- Air Freight: Faster delivery for urgent orders.

- Land Freight: Suitable for cross-border shipments.

- Multimodal Transport: A combination of sea, air, and land transportation for optimal delivery solutions.

- Courier Services: For small, urgent shipments.

Contact Us

Ready to place an order or have more questions? Contact us today to discuss your zirconium sheet needs. We are dedicated to providing you with high-quality products and excellent customer service. Email us at info@peakrisemetal.com and let’s work together to bring your heat exchanger projects to life!

This comprehensive product page is designed to provide potential customers with all the information they need about our zirconium sheets for heat exchangers. By highlighting the product’s unique features, applications, and the advantages of working with Shaanxi Peakrise Metal Co., Ltd., we aim to turn interest into action and boost customer conversions.