Zirconium Sheet for Chemical Use

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Sheet for Chemical Use - Shaanxi Peakrise Metal Co., Ltd.

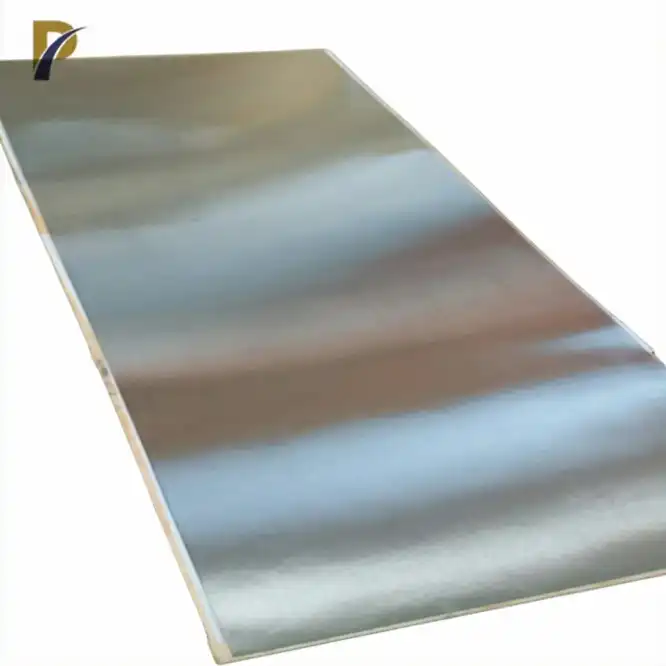

Product Introduction

Zirconium sheets play a crucial role in various chemical industries due to their exceptional resistance to corrosion and high-temperature environments. As a leading supplier of high-quality zirconium sheets for chemical applications, Shaanxi Peakrise Metal Co., Ltd. delivers reliable, high-performance materials to customers worldwide. Our zirconium sheets are specifically designed to meet the rigorous demands of the chemical processing industry, providing exceptional durability and corrosion resistance, even in the most extreme conditions. Whether exposed to highly acidic or alkaline environments, our zirconium sheets remain stable, making them ideal for heat exchangers, reaction vessels, and other critical equipment used in chemical processing.

With over a decade of experience in the production and export of non-ferrous metals, Shaanxi Peakrise Metal Co., Ltd. is committed to providing products that meet international standards for safety and quality. Our state-of-the-art manufacturing processes and stringent quality control ensure that each zirconium sheet meets the specific requirements of our clients. We are proud to serve a global market, exporting our products to countries such as the United States, Germany, South Korea, and Australia. Our success is built on delivering high-performance materials that customers trust.

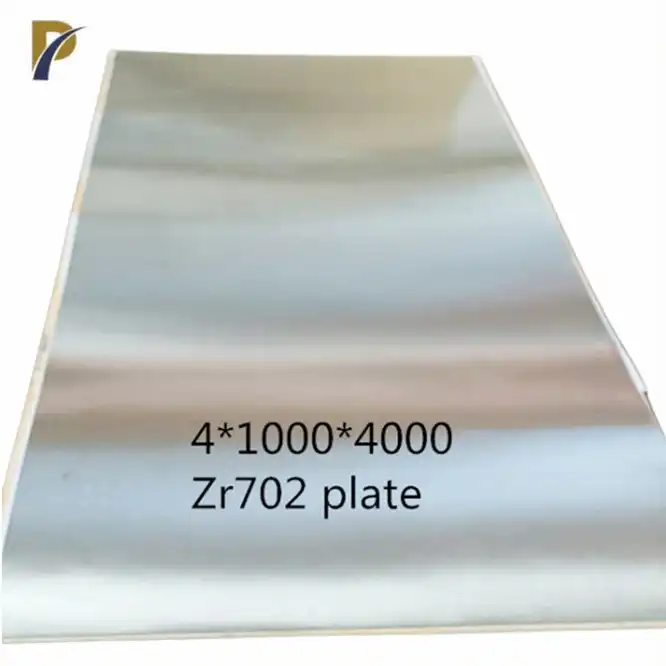

Product Specifications

| Parameter | Value |

|---|---|

| Purity | Zr + Hf ≥ 99.2% |

| Thickness Range | 0.5mm – 50mm |

| Width Range | 100mm – 1000mm |

| Length Range | 500mm – 3000mm |

| Density | 6.51 g/cm³ |

| Tensile Strength | 379 MPa |

| Melting Point | 1855°C |

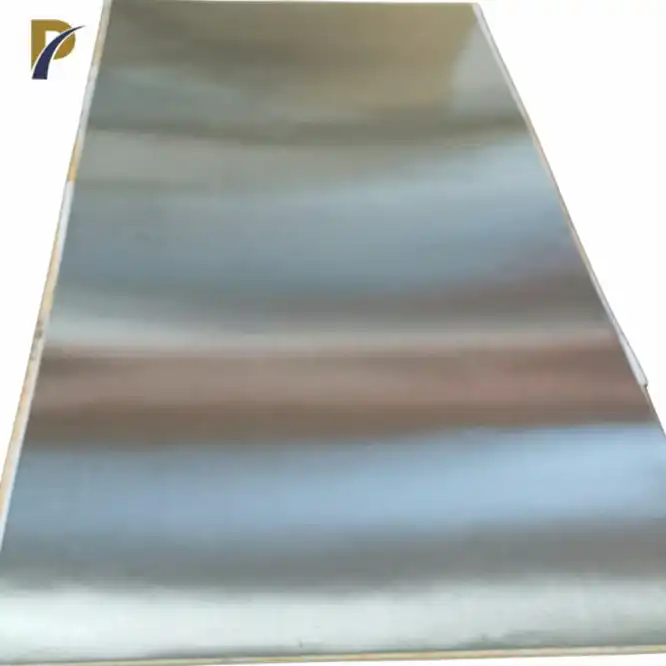

| Surface Finish | Cold rolled, polished |

| Chemical Composition | Percentage (%) |

|---|---|

| Zirconium (Zr) | ≥ 99.2% |

| Hafnium (Hf) | ≤ 4.5% |

| Iron (Fe) | ≤ 0.2% |

| Nitrogen (N) | ≤ 0.03% |

| Silicon (Si) | ≤ 0.15% |

| Carbon (C) | ≤ 0.05% |

| Mechanical Properties | Value |

|---|---|

| Yield Strength | 207 MPa |

| Elongation at Break | 20% |

| Hardness | 90 HB |

| Thermal Conductivity | 22 W/m·K |

| Modulus of Elasticity | 97 GPa |

| Electrical Resistivity | 42 nΩ·m |

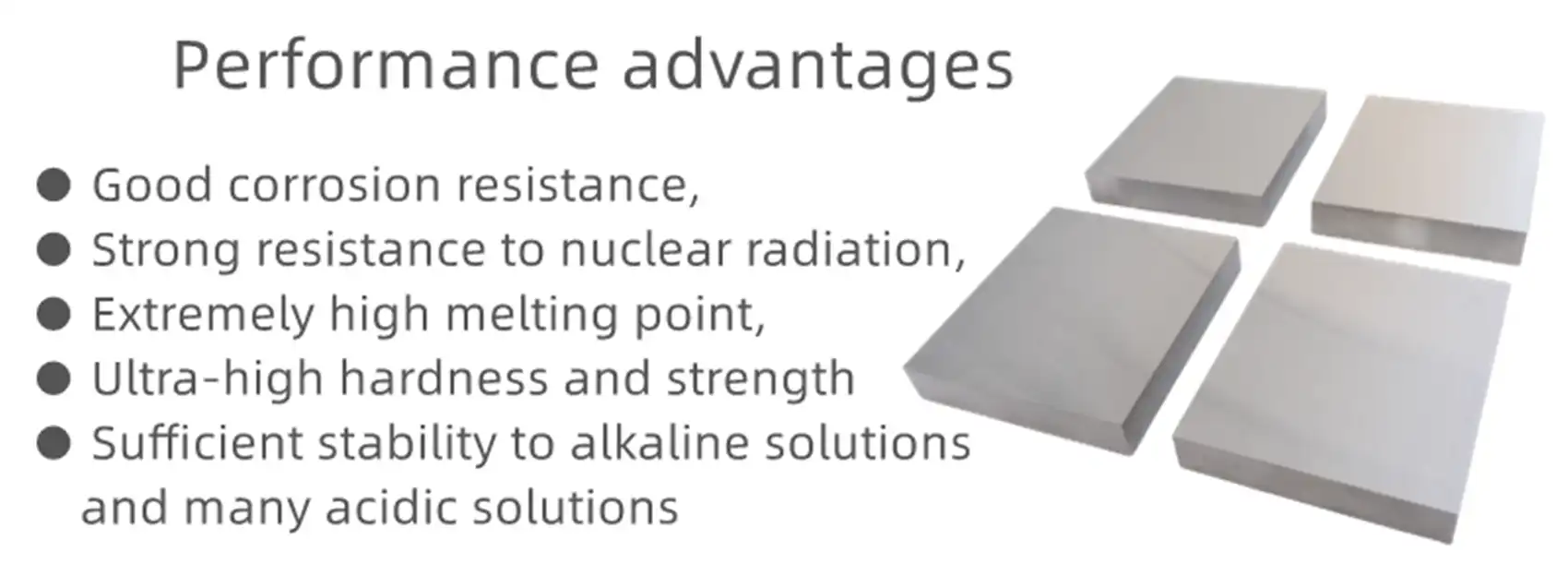

Physical and Chemical Properties

Zirconium's unique properties make it an outstanding material for chemical use. Its high melting point (1855°C) and low thermal conductivity (22 W/m·K) allow it to withstand extreme heat, while its resistance to acids, alkalis, and seawater prevents corrosion in harsh environments. Additionally, zirconium's compatibility with hydrogen and oxygen enables it to perform well in chemical reactions where high-temperature resistance is required.

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

Product Functions

- Corrosion Resistance: Zirconium sheets offer unparalleled resistance to corrosion, especially in environments involving strong acids like hydrochloric and sulfuric acid, making them ideal for chemical reactors and storage tanks.

- High-Temperature Stability: With a melting point of 1855°C, zirconium sheets can handle extreme temperatures, ensuring long-lasting performance in heat exchangers and thermal reactors.

- Structural Integrity: Despite its lightweight nature, zirconium has a high tensile strength, making it a durable option for equipment exposed to mechanical stress or chemical wear.

- Chemical Reactivity: Zirconium's low reactivity with gases like hydrogen and oxygen allows for safe usage in chemical processes, minimizing contamination or unwanted reactions.

- Electrical Conductivity: While zirconium has low electrical conductivity, its stability in high-temperature environments makes it a suitable material for certain electrochemical processes.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Product Applications

Zirconium sheets are widely used across industries due to their unique properties. Below are some of the key applications:

- Chemical Processing: Zirconium is a critical material in chemical reactors, heat exchangers, and evaporators, providing resistance to corrosion in acidic and alkaline environments.

- Nuclear Industry: With low neutron absorption properties, zirconium is commonly used in nuclear reactors for cladding fuel rods and other reactor components.

- Aerospace Engineering: In aerospace, zirconium's resistance to heat and corrosion makes it suitable for high-performance components, such as fuel tanks and engine parts.

- Medical Devices: Thanks to its biocompatibility, zirconium sheets are utilized in medical implants and surgical tools that must endure both bodily fluids and sterilization processes.

- Water Treatment: Zirconium's anti-corrosive nature and ability to withstand harsh chemicals make it an ideal choice for desalination plants and wastewater treatment facilities.

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd., our zirconium sheets are produced using advanced manufacturing techniques:

- Raw Material Selection: We source high-purity zirconium to ensure the best material properties for our products.

- Melting: The raw material is melted in a vacuum arc furnace, minimizing impurities and creating a uniform composition.

- Rolling and Shaping: After melting, the zirconium is hot-rolled and cold-rolled into sheets of the desired thickness and dimensions.

- Annealing: The sheets are annealed in a vacuum furnace to relieve internal stresses, enhancing mechanical properties.

- Finishing: The final product undergoes surface finishing to ensure a smooth, polished surface suitable for industrial applications.

|

|

|

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer custom zirconium sheets tailored to meet your specific requirements. Whether you need a particular size, thickness, or surface finish, our team is here to provide flexible OEM and ODM services to suit your industrial needs.

|

|

FAQ

-

What is the typical lead time for zirconium sheet orders?

Our standard lead time is 4-6 weeks, depending on the order size and customization requirements. -

Can you provide certification for the zirconium sheets?

Yes, we offer full material certification, including composition and mechanical property reports. -

Do you offer samples for testing?

Yes, we provide small samples for testing and evaluation upon request. -

What is the minimum order quantity (MOQ)?

Our MOQ typically starts at 50kg, but we can accommodate smaller orders for certain projects. -

What are your payment terms?

We offer flexible payment terms, including T/T and L/C, based on customer requirements.

Packaging

Our zirconium sheets are carefully packaged to ensure safe delivery:

- Wooden Box Packaging: Heavy-duty wooden crates ensure protection during long-haul shipments.

- Carton Packaging: Smaller orders are packed in durable cartons with foam filling to prevent damage.

- Foam Filling: Soft foam layers cushion the zirconium sheets during transit.

- Waterproof and Moisture-Proof: All packaging materials are moisture-resistant to protect the product from humidity.

- Custom Packaging: We offer custom packaging solutions to meet the specific needs of our customers.

Logistics

We provide a range of shipping options to suit your timeline and budget:

- Sea Freight: Ideal for bulk orders, offering economical shipping.

- Air Freight: Expedited shipping for urgent orders.

- Land Freight: For regional deliveries across the continent.

- Multimodal Transport: A combination of sea, air, and land transport to optimize delivery.

- Courier Services: For smaller, time-sensitive shipments.

|

|

Contact Us

Contact us today to discuss your zirconium sheet requirements and how we can support your next project. Shaanxi Peakrise Metal Co., Ltd. is your trusted partner for high-performance zirconium sheets designed for chemical use. Email us at info@peakrisemetal.com to request a quote or learn more about our products and services.

We look forward to working with you!