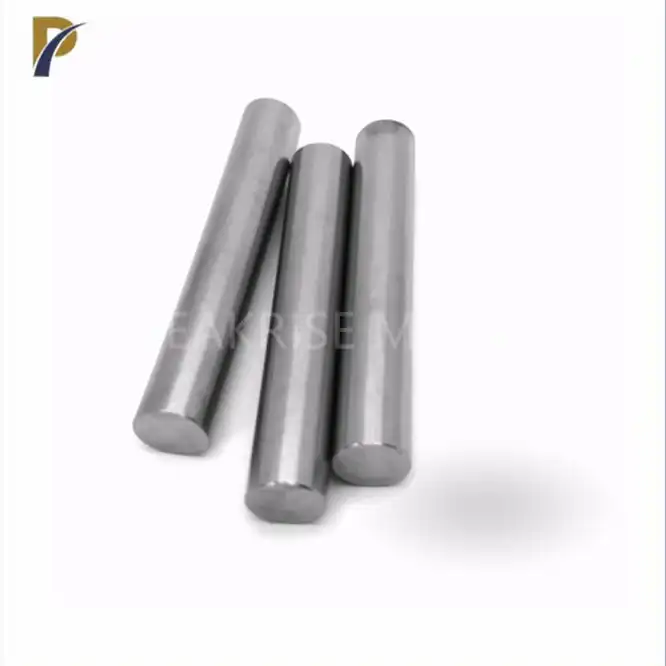

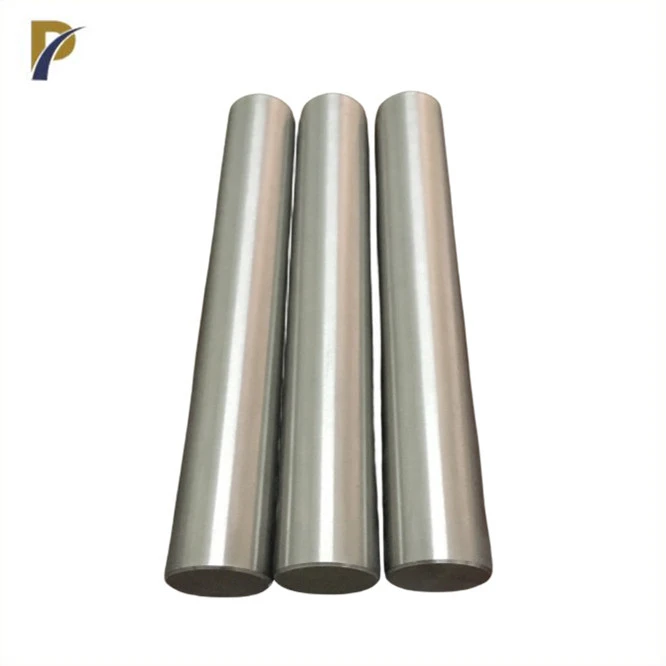

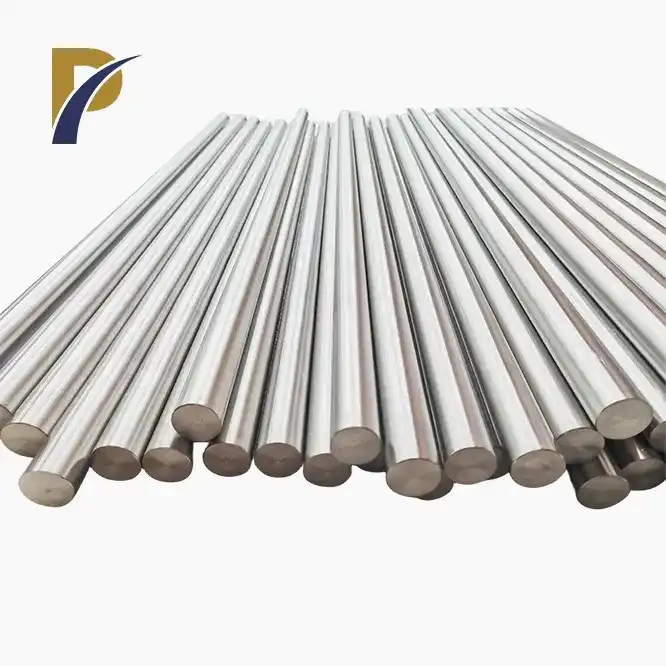

Zirconium Alloy Metal Rods

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Alloy Metal Rods by Shaanxi Peakrise Metal Co., Ltd.: Your Reliable Supplier for High-Performance Materials

At Shaanxi Peakrise Metal Co., Ltd., we take pride in being a leading supplier of Zirconium Alloy Metal Rods, trusted by industries worldwide. With a reputation for delivering premium non-ferrous metal products, we specialize in the production of zirconium alloy rods, which are widely recognized for their excellent properties, such as high resistance to corrosion, outstanding strength, and superior thermal conductivity. Our zirconium alloy rods are critical in industries that require advanced material solutions, including aerospace, nuclear, medical, and chemical sectors. Leveraging our experience and state-of-the-art production techniques, we ensure that each zirconium alloy rod meets the stringent requirements of our global customers.

Our Zirconium Alloy Metal Rods are manufactured to the highest standards, offering unparalleled performance in environments that demand resistance to extreme temperatures, corrosion, and wear. Shaanxi Peakrise Metal Co., Ltd. has established itself as a reliable and long-term partner for industries that depend on high-quality zirconium alloys for their operations. With over a decade of experience in non-ferrous metal production, we are committed to providing superior products that meet the evolving needs of the global market.

Product Specifications

| Parameter | Value |

|---|---|

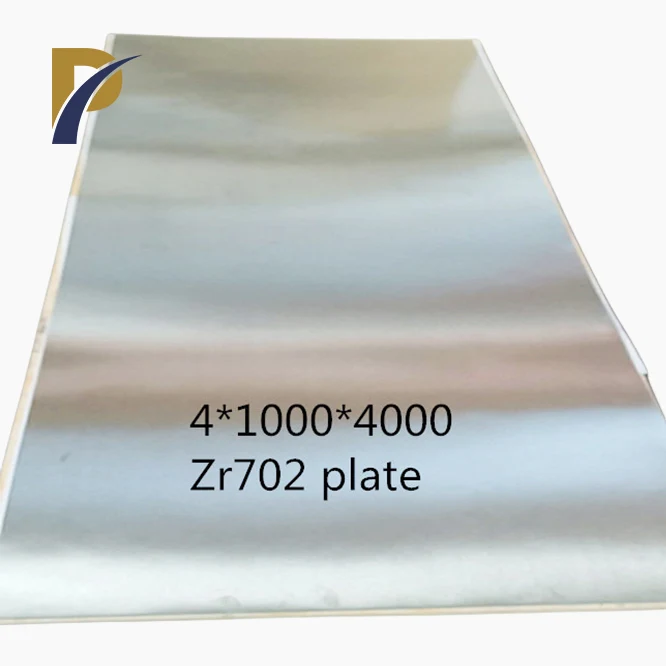

| Alloy Composition | Zr702, Zr705 |

| Density | 6.51 g/cm³ |

| Melting Point | 1855°C |

| Thermal Conductivity | 22 W/m·K |

| Tensile Strength | 379 MPa (Zr702) |

| Elongation | 30% (Zr702) |

| Standard Dimensions | Ø 6mm to Ø 200mm |

| Available Lengths | 1000mm - 3000mm |

| Surface Finish | Bright, Polished |

| Parameter | Value |

|---|---|

| Yield Strength (Zr702) | 207 MPa |

| Hardness | 160 HV |

| Modulus of Elasticity | 99.3 GPa |

| Heat Treatment | Annealed |

| Tolerances | ±0.01mm |

| Chemical Composition (Zr + Hf) | ≥ 99.2% |

| Parameter | Value |

|---|---|

| Corrosion Resistance | Excellent |

| Electrical Resistivity | 421 nΩ·m |

| Specific Heat Capacity | 0.278 J/g·K |

| Thermal Expansion Coefficient | 5.7 µm/m·K |

| Available Shapes | Rods, Bars, Custom Profiles |

| Custom Sizes | Available Upon Request |

| Minimum Order Quantity | 1 kg |

|

|

|

Physical and Chemical Properties

Zirconium alloy rods exhibit superior corrosion resistance, particularly in aggressive environments such as acidic or alkaline solutions. This makes them ideal for use in the nuclear industry, where durability and reliability are paramount. With their high melting point of 1855°C and low thermal neutron absorption cross-section, zirconium alloys are critical materials for nuclear reactors. Additionally, these rods possess excellent thermal conductivity, ensuring efficient heat dissipation in high-temperature applications. Their mechanical strength, combined with lightweight properties, offers exceptional performance in demanding structural applications.

Product Features and Functions

-

Corrosion Resistance: Zirconium alloy rods resist corrosion from a wide range of chemicals, making them suitable for use in highly reactive environments, such as nuclear reactors and chemical processing plants.

-

High Melting Point: These rods can withstand extreme temperatures, making them ideal for use in high-heat applications, including aerospace and industrial furnaces.

-

Thermal Conductivity: With excellent thermal conductivity, zirconium alloys efficiently transfer heat, reducing the risk of overheating in sensitive systems like medical devices and power generation equipment.

-

Structural Strength: Despite their lightweight properties, zirconium alloy rods offer remarkable mechanical strength and resistance to wear, ensuring long-term durability in applications that require both toughness and flexibility.

-

Low Neutron Absorption: The low absorption of thermal neutrons makes zirconium alloys critical in nuclear applications, particularly for cladding fuel rods in nuclear reactors.

Manufacturing Process

At Shaanxi Peakrise Metal Co., Ltd., our Zirconium Alloy Metal Rods are produced using advanced manufacturing processes to ensure optimal quality and performance. The process begins with high-purity zirconium raw materials, which are melted in a vacuum arc furnace. The melted zirconium is then cast into billets and rolled into rods of various dimensions. After the rolling process, the rods undergo heat treatment in a vacuum annealing furnace to achieve the desired mechanical properties. Finally, the rods are inspected for dimensional accuracy and surface finish before being packaged for delivery.

Why Choose Shaanxi Peakrise Metal Co., Ltd?

-

Extensive Industry Experience: With over a decade of experience in non-ferrous metal production, we have become a trusted name in the industry.

-

Comprehensive Product Range: We specialize in a wide variety of non-ferrous metal products, including tungsten-copper alloys, molybdenum-copper alloys, tantalum alloys, and more.

-

High-Quality Standards: Our zirconium alloy rods meet international standards such as ASTM B550 , ensuring reliability and performance in critical applications.

-

State-of-the-Art Equipment: Our factory is equipped with advanced machinery, including vacuum arc furnaces, laser cutters, and rolling mills, allowing us to produce products with precision and efficiency.

-

Global Reach: We export to numerous countries, including the United States, Germany, South Korea, and Australia, establishing long-term partnerships with satisfied customers worldwide.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM and ODM services to cater to the unique needs of our clients. We provide customization options, including specific dimensions, finishes, and alloy compositions, to meet the exact requirements of different industries. Whether you need standard zirconium alloy rods or bespoke solutions, we have the capabilities to deliver high-quality products tailored to your specifications.

|

|

|

|

|

|

|

|

|

|

FAQ

-

What are the main advantages of zirconium alloy rods?

- Zirconium alloy rods offer exceptional corrosion resistance, high temperature tolerance, and excellent thermal conductivity, making them ideal for demanding industrial applications.

-

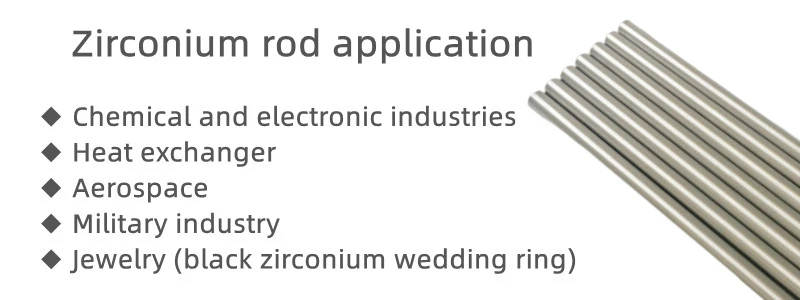

What industries commonly use zirconium alloy rods?

- Zirconium alloy rods are widely used in the nuclear, aerospace, medical, and chemical industries due to their unique properties.

-

Can I order custom-sized zirconium alloy rods?

- Yes, we offer custom dimensions and tolerances based on your specific requirements. Contact us for more details on custom orders.

-

What standards do your zirconium alloy rods meet?

- Our zirconium alloy rods comply with ASTM B550 and B493 standards, ensuring quality and performance.

-

What is the typical lead time for orders?

- The lead time depends on the order quantity and specifications. Typically, we can deliver within 4-6 weeks for most standard orders.

Packaging and Logistics

-

Packaging:

- Wooden crates for heavy-duty protection

- Cardboard boxes for lightweight shipments

- Foam inserts for cushioning

- Waterproof and moisture-proof packaging for sensitive goods

- Customized packaging options available upon request

- All packaging meets international shipping standards.

-

Logistics:

- Sea Freight for large orders

- Air Freight for urgent deliveries

- Land Transportation for regional deliveries

- Multimodal Transport for cost-effective solutions

- Express Delivery for small and time-sensitive shipments

|

|

|

|

|

|

|

|

|

|

Contact Us

Ready to discuss your zirconium alloy rod requirements? Contact us today to explore how Shaanxi Peakrise Metal Co., Ltd. can meet your needs. Our experienced team is here to provide expert guidance and top-quality products. Get in touch with us at info@peakrisemetal.com to learn more about our offerings or to request a quote. We look forward to partnering with you for your next project.

YOU MAY LIKE

-

VIEW MOREZirconium Pipes for Chemical Use

VIEW MOREZirconium Pipes for Chemical Use -

VIEW MORECustom Zirconium Crucibles for ICP-OES Laboratory Purification Zirconium Crucible Zr702 Zr Crucible

VIEW MORECustom Zirconium Crucibles for ICP-OES Laboratory Purification Zirconium Crucible Zr702 Zr Crucible -

VIEW MOREWedding Band Zirconium Ring

VIEW MOREWedding Band Zirconium Ring -

VIEW MOREZirconium Wire for Specialized Applications

VIEW MOREZirconium Wire for Specialized Applications -

VIEW MOREZirconium Foil Sheets for Fabrication

VIEW MOREZirconium Foil Sheets for Fabrication -

VIEW MOREZirconium Chemical Industry Rod UNS R60702 Zr702 ZR2

VIEW MOREZirconium Chemical Industry Rod UNS R60702 Zr702 ZR2 -

VIEW MORECorrosion-Resistant Zirconium Sheets

VIEW MORECorrosion-Resistant Zirconium Sheets -

VIEW MOREZirconium Alloy Bars Zr705 R60804

VIEW MOREZirconium Alloy Bars Zr705 R60804