Zirconium Chemical Industry Rod UNS R60702 Zr702 ZR2

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

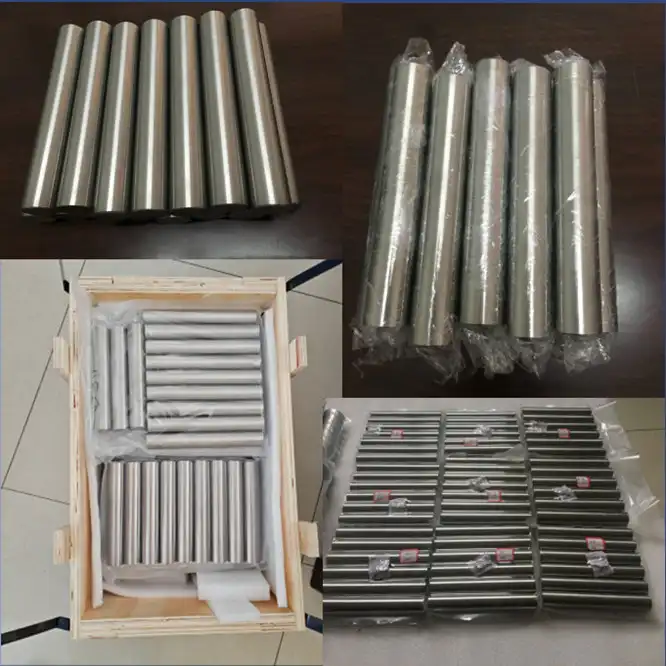

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Chemical Industry Rod Product Page for Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Zirconium Chemical Industry Rods play a crucial role in various industrial applications due to their exceptional corrosion resistance and high-temperature stability. These rods are widely used in environments where chemical exposure is severe, including the chemical processing industry, nuclear reactors, and pharmaceutical manufacturing. Their ability to resist corrosion from strong acids, alkalis, and other corrosive agents makes them indispensable in sectors where material integrity is critical.

Shaanxi Peakrise Metal Co., Ltd. is a trusted supplier of high-quality zirconium rods, offering products that meet the stringent demands of the chemical industry. Our expertise in producing zirconium chemical industry rods stems from years of research, development, and innovation in non-ferrous metal production. Our zirconium rods are manufactured with precision, adhering to international standards to ensure reliable performance in critical applications. With a comprehensive approach to quality control, we ensure that our zirconium rods meet the specific needs of industries globally.

Product Specifications

| Product Name | Zirconium Chemical Industry Rod UNS R60702 Zr702 ZR2 |  |

| Grade | Zr702,Zr705,RO60804,RO60001,RO60901 | |

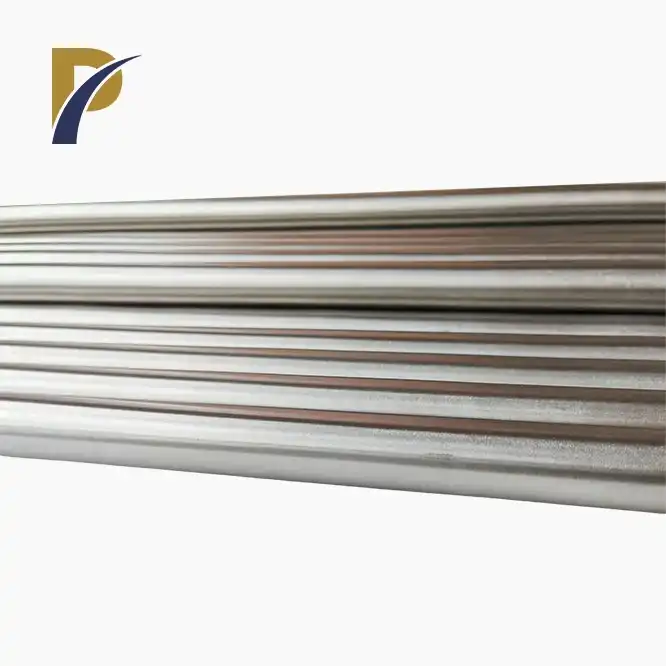

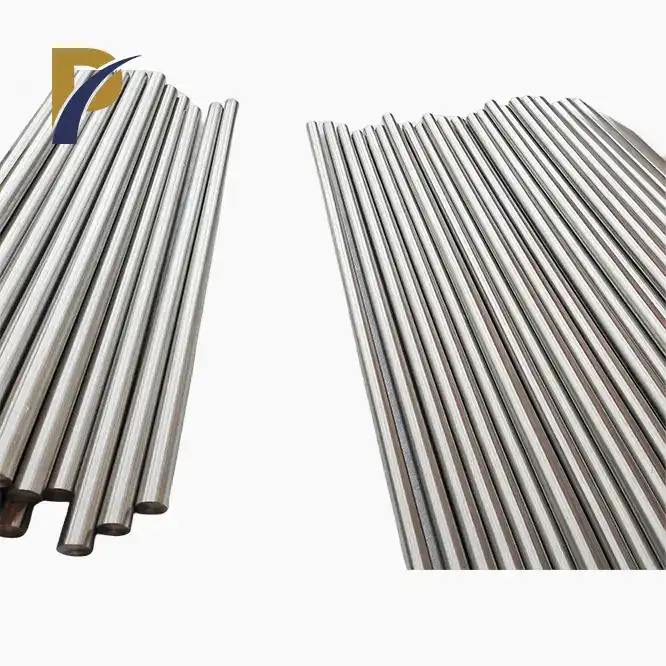

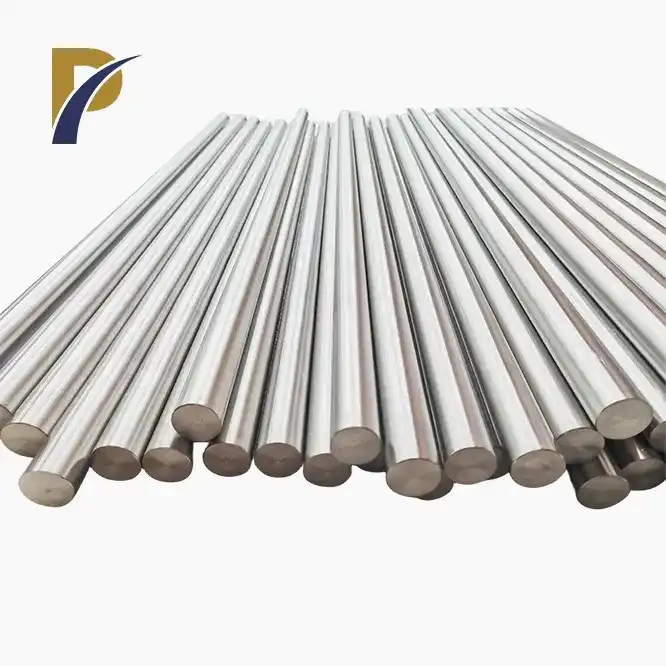

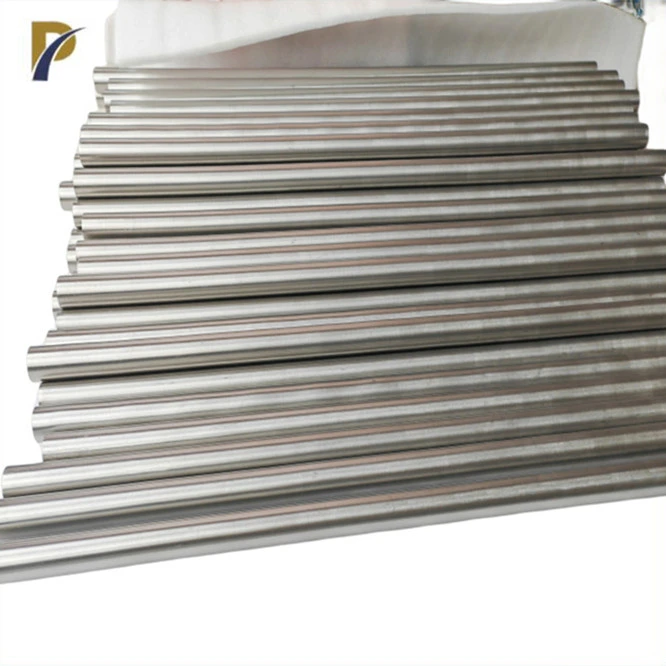

| Common size | φ2-φ100mm or according to customer's request. | |

| Length | <12000mm or as per customer request. | |

| Standard | ASTM B550 | |

| Purity | >99.7% | |

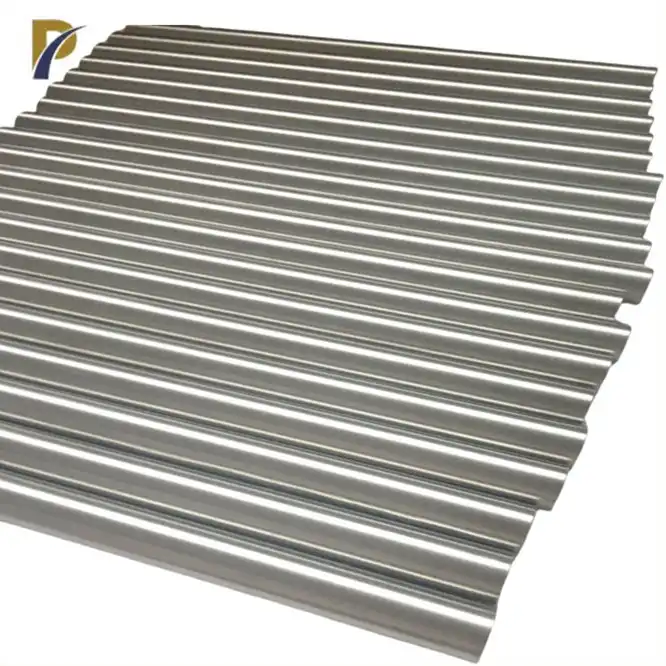

| Surface | Polished | |

| Application |

▲ Chemical Industry , ▲ Jewelry industry, ▲ Aerospace |

|

|

Physical and Chemical Properties

- Corrosion Resistance: Exceptional resistance to acids, alkalis, and other aggressive chemicals, making zirconium rods ideal for harsh environments.

- High Temperature Stability: Zirconium rods maintain their structural integrity at high temperatures, which is critical for industries like chemical processing and nuclear power.

- Low Thermal Neutron Absorption: This unique property makes zirconium rods suitable for nuclear applications, especially in the construction of reactor components.

- Non-magnetic and Conductive Properties: The rods are non-magnetic and possess moderate electrical conductivity, adding versatility to their industrial use.

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

Product Applications

- Chemical Processing Industry: Zirconium rods are extensively used in chemical plants due to their resistance to corrosive agents. They are commonly found in reactors, tanks, and pipelines where exposure to harsh chemicals is constant.

- Nuclear Power Plants: In nuclear reactors, zirconium rods are used in fuel rod cladding because of their low neutron absorption and high temperature tolerance.

- Pharmaceutical Industry: Zirconium rods are used in the production of pharmaceutical equipment that comes into contact with corrosive substances during the manufacturing process.

- Aerospace and Defense: The aerospace sector utilizes zirconium rods for their high strength-to-weight ratio and corrosion resistance, which are critical in high-performance applications.

- Medical Devices: Zirconium’s biocompatibility makes it ideal for medical implants and surgical tools that require both durability and safety.

Manufacturing Process

The production of zirconium chemical industry rods at Shaanxi Peakrise Metal Co., Ltd. follows a rigorous process designed to ensure product quality and consistency:

- Raw Material Selection: High-purity zirconium is sourced and inspected for quality.

- Melting and Casting: The zirconium is melted using vacuum arc melting furnaces, ensuring a homogenous material composition.

- Rolling and Drawing: The cast zirconium is hot-rolled and drawn into rods of the desired diameter, ensuring dimensional accuracy.

- Annealing: The rods undergo vacuum annealing to enhance their mechanical properties and corrosion resistance.

- Quality Control: Each rod is subjected to stringent quality checks, including dimensional inspection, chemical analysis, and mechanical testing.

|

|

|

Factory Overview

Shaanxi Peakrise Metal Co., Ltd. boasts state-of-the-art facilities equipped with the latest technology to ensure high-quality zirconium production. Our factory is outfitted with intermediate frequency sintering furnaces, vacuum arc melting furnaces, plasma electron beam melting systems, and CNC machinery. Our production process is supported by a dedicated R&D department that constantly works to improve material properties and processing methods. This combination of advanced equipment and skilled labor allows us to provide top-tier products to our global clientele.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

- Packaging: We offer a variety of packaging solutions to ensure that the zirconium rods are delivered in perfect condition. Options include wooden crates, cardboard boxes, foam padding, moisture-resistant packaging, and custom packaging tailored to specific needs.

- Logistics: Our logistics options cover global shipping, including:

- Sea Freight

- Air Freight

- Land Transportation

- Multimodal Transport

- Express Services for urgent orders

|

|

Why Choose Us?

- Expertise: With over a decade of experience in non-ferrous metal production, we have honed our skills in manufacturing high-quality zirconium rods.

- Advanced Technology: Our state-of-the-art facilities and equipment allow us to produce rods with unmatched precision and consistency.

- Global Reach: Our products are exported to over 10 countries, including the USA, Germany, South Korea, and Australia.

- Quality Assurance: Every product undergoes strict testing to ensure that it meets international standards.

- Customer-Centric Approach: We prioritize customer satisfaction and work closely with clients to provide tailored solutions.

Frequently Asked Questions (FAQ)

-

What is the purity of your zirconium rods?

Our zirconium rods have a purity of 99.95%, ensuring high performance in corrosive environments. -

Do you offer custom sizes?

Yes, we offer customizable diameters and lengths to meet the specific needs of your application. -

What industries can benefit from zirconium rods?

Zirconium rods are widely used in chemical processing, nuclear power plants, pharmaceuticals, aerospace, and medical equipment. -

How do you ensure product quality?

We follow a rigorous quality control process, including chemical composition analysis, dimensional inspections, and mechanical testing. -

Can you handle large-scale orders?

Yes, our factory is equipped to handle bulk orders while maintaining strict quality standards.

Call to Action (CTA) - Contact Us

Looking for high-quality zirconium rods for your chemical or industrial applications? Shaanxi Peakrise Metal Co., Ltd. is here to meet your needs. With a proven track record of excellence, we supply durable, high-performance zirconium rods tailored to your specifications. Reach out to us at info@peakrisemetal.com today to discuss your project requirements and discover how we can provide solutions that enhance your operations.

Let us help you build a stronger, more efficient future with the power of zirconium!