Zirconium Pipes for Chemical Use

Model Number:Custom

Minimum Order Quantity:1kg

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Pipes for Chemical Use - Shaanxi Peakrise Metal Co., Ltd.

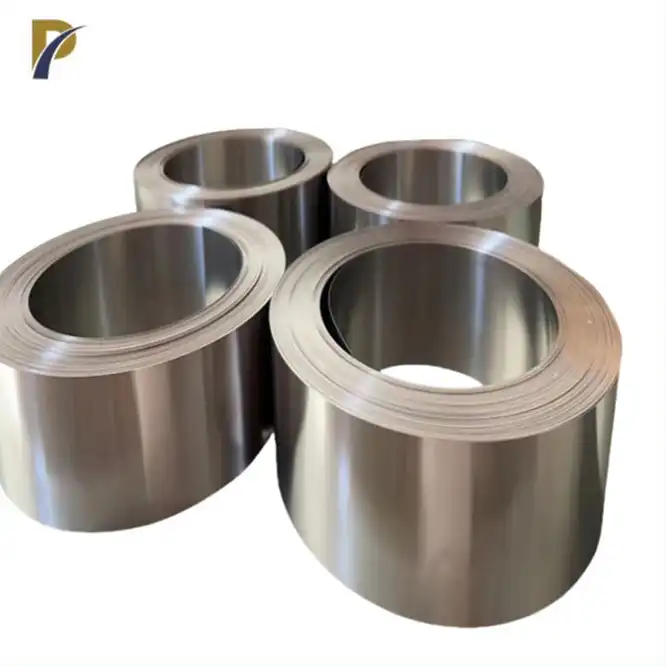

Product Introduction

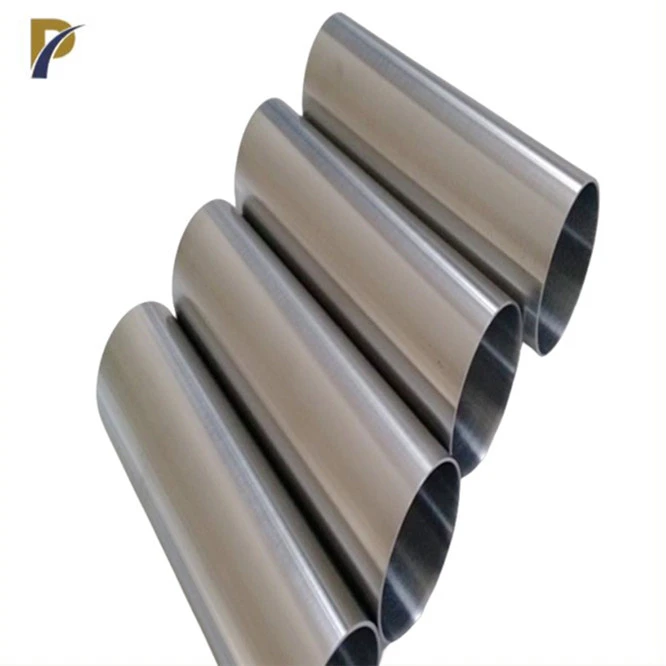

Zirconium pipes are an essential material in industries where extreme chemical resistance is required, particularly in aggressive environments where other metals would corrode or degrade quickly. Due to its outstanding resistance to many acids, alkalis, and salt solutions, zirconium is the material of choice for chemical processing plants, power generation, and other industrial applications. Shaanxi Peakrise Metal Co., Ltd. is a trusted supplier of zirconium pipes for chemical use, providing high-quality materials to meet the stringent requirements of modern industry.

With more than a decade of experience in the production and export of non-ferrous metals, including zirconium, Peakrise Metal has established itself as a leading manufacturer serving clients worldwide. Our zirconium pipes are meticulously engineered to meet industry standards and perform in the most demanding chemical environments. We utilize cutting-edge production processes, ensuring that our pipes maintain high mechanical strength, durability, and exceptional resistance to corrosive chemicals.

At Peakrise Metal, we prioritize product quality and customer satisfaction. Our team of experts works closely with clients to deliver customized solutions tailored to specific industry requirements. As a global supplier, we have forged long-term relationships with clients in the United States, Europe, Asia, and beyond, offering not just materials but also reliable technical support and responsive service. Whether you need standard specifications or custom designs, Peakrise Metal is here to meet your needs.

Product Specifications

| Parameter | Specification 1 | Specification 2 | Specification 3 |

|---|---|---|---|

| Outer Diameter (mm) | 25.4 - 219.1 | 19.05 - 168.3 | 12.7 - 101.6 |

| Wall Thickness (mm) | 2.0 - 12.7 | 1.65 - 6.35 | 0.89 - 4.57 |

| Length (mm) | Up to 6000 | Up to 5000 | Up to 3000 |

| Material Grade | Zr702, Zr705 | Zr702, Zr705 | Zr702, Zr705 |

| Standard | ASTM B523, ASME SB523 | ASTM B523, ASME SB523 | ASTM B523, ASME SB523 |

| Surface Finish | Polished, pickled, sandblasted | Polished, pickled, sandblasted | Polished, pickled, sandblasted |

| Standard | Grade | Status | Rm(≥)/MPa | Rp0.2(≥)/MPa | A51mm(≥)/% |

| ASTM B658 Zr seamless tube/welding pipe |

R60702 R60704 R60705 |

Annealed |

379 413 552 |

207 241 379 |

16 14 16 |

| ASTM B523 Zr seamless & welding heat exchange tube |

R60702 R60704 R60705 |

Annealed |

379 413 552 |

207 241 379 |

16 14 16 |

|

|

|

Physical and Chemical Properties

Zirconium possesses a unique combination of chemical and physical properties, making it ideal for chemical use:

- Density: 6.52 g/cm³

- Melting Point: 1855°C

- Boiling Point: 4409°C

- Corrosion Resistance: Exceptional resistance to many corrosive environments, including sulfuric acid, hydrochloric acid, and organic solvents.

- Thermal Conductivity: High thermal conductivity, which is beneficial in heat exchangers and similar equipment.

- Mechanical Strength: High tensile strength and durability under extreme conditions.

| Grade | Element composition(%)< | Standard | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | ||

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 | ASTM B658 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- | |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 | |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 | |

| R60804 | 97.5 | 0.01 | 0.25~0.37 | 1.2~1.7 | 0.0025 | 0.008 | 0.027 | -- | 0.09~0.16 | ASTM B353 |

| R60001 | 99.9 | 0.01 | 0.17 | 0.005 | 0.0025 | 0.008 | 0.027 | -- | -- | |

Product Functions

- Corrosion Resistance: Zirconium pipes are renowned for their superior corrosion resistance, making them ideal for handling harsh chemicals such as strong acids and alkalis in industrial processes.

- High Thermal Stability: These pipes maintain their structural integrity and mechanical properties even at high temperatures, ensuring consistent performance in extreme environments.

- Durability: Zirconium’s resistance to wear and tear makes these pipes highly durable, offering long service life in chemical processing plants and power generation facilities.

- Chemical Purity: Zirconium has a very low impurity level, which is essential when used in industries such as pharmaceuticals, where product contamination is a significant concern.

Product Applications

- Chemical Processing Plants: Zirconium pipes are widely used in the manufacturing and processing of chemicals where their corrosion resistance and durability ensure reliable and safe operations.

- Nuclear Power Generation: Zirconium’s ability to withstand extreme heat and radiation makes it an essential material in nuclear reactors for handling radioactive materials safely.

- Pharmaceutical Industry: The purity and chemical resistance of zirconium make it suitable for pharmaceutical production, where maintaining the integrity of the materials being processed is critical.

- Desalination Plants: The resistance of zirconium pipes to saline and harsh water environments makes them ideal for use in desalination plants, ensuring long-lasting performance.

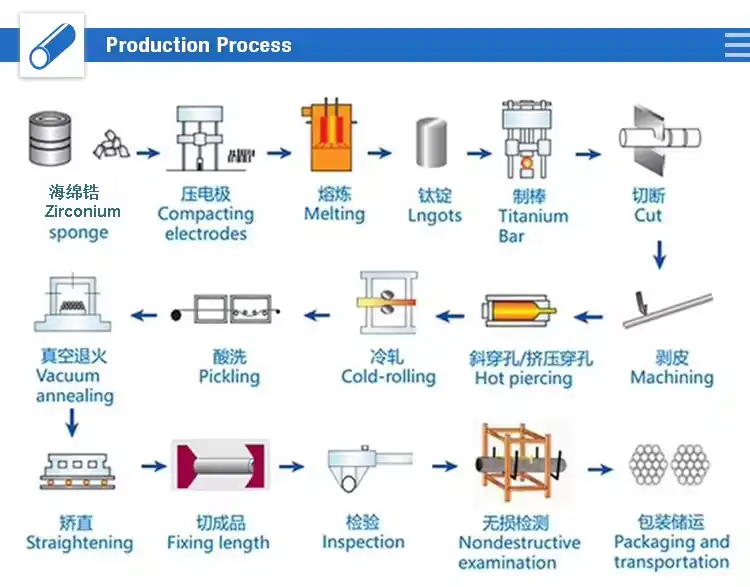

Manufacturing Process and Production Flow

The production of zirconium pipes at Shaanxi Peakrise Metal Co., Ltd. involves several steps to ensure the highest quality product:

- Raw Material Selection: We use only premium-grade zirconium (Zr702, Zr705) sourced from reliable suppliers.

- Melting: The zirconium is melted in a vacuum arc melting furnace to remove impurities and create a homogenous material.

- Forming: Using advanced rolling mills and extrusion processes, the zirconium is formed into pipe shapes with precise dimensions.

- Heat Treatment: The pipes undergo vacuum annealing to improve their mechanical properties.

- Testing and Inspection: Each pipe is rigorously tested for dimensional accuracy, chemical composition, and mechanical properties to ensure they meet international standards.

- Final Finishing: The pipes are finished through polishing, pickling, or sandblasting, depending on the client’s requirements.

About Shaanxi Peakrise Metal Co., Ltd.

Shaanxi Peakrise Metal Co., Ltd. is an experienced manufacturer specializing in the production of non-ferrous and refractory metals, including tungsten, molybdenum, tantalum, niobium, titanium, and zirconium. Since 2010, we have been supplying high-quality products to the global market, focusing on industries that demand superior materials and performance. With advanced production equipment and a team of skilled engineers, we deliver products that meet the highest industry standards.

Our factory is equipped with state-of-the-art machinery, including vacuum arc melting furnaces, plasma electron beam melting furnaces, rolling mills, and CNC machines. This ensures that we can produce zirconium pipes of the highest quality, tailored to meet the specific needs of each customer.

|

|

|

Packaging and Logistics

- Wooden Crate Packaging: Secure and sturdy wooden crates to protect pipes during transportation.

- Cardboard Box Packaging: Lightweight and cost-effective packaging for smaller quantities.

- Foam Filling: Provides additional protection by absorbing shocks and vibrations during shipping.

- Waterproof and Moisture-Proof Packaging: Ensures that pipes are protected from moisture damage during transit.

- Custom Packaging: We offer custom packaging solutions to meet the specific needs of our clients.

- International Standard Packaging: All packaging complies with international shipping standards to ensure safe delivery.

|

|

|

|

|

|

|

|

|

|

Logistics options:

- Sea Freight: Cost-effective option for large orders.

- Air Freight: Fast and reliable for urgent deliveries.

- Land Freight: Ideal for local or cross-border transportation.

- Multimodal Transport: A combination of sea, air, and land transport for optimal logistics solutions.

- Courier Service: Express delivery for smaller, time-sensitive shipments.

Why Choose Us?

- Extensive Experience: With over 10 years in the non-ferrous metal industry, we have the expertise to deliver high-quality products that meet the needs of our clients.

- Custom Solutions: We provide OEM services to meet the specific requirements of our customers.

- Global Reach: Our products are exported to countries around the world, including the United States, Germany, South Korea, and more.

- Advanced Equipment: Our factory is equipped with state-of-the-art machinery, ensuring precise manufacturing and testing of our products.

- Quality Assurance: Every product undergoes strict testing to ensure it meets international standards for performance and durability.

OEM Services

At Shaanxi Peakrise Metal Co., Ltd., we offer comprehensive OEM and ODM services. Whether you need pipes in non-standard dimensions or custom surface treatments, our team can work with you to develop a product that meets your exact requirements. We also provide labeling and packaging customization to suit your branding needs.

|

|

|

|

|

|

|

|

|

|

FAQs

-

What grades of zirconium do you offer?

We offer zirconium pipes in Zr702 and Zr705 grades, both of which provide excellent corrosion resistance and mechanical properties. -

Can you produce custom sizes?

Yes, we offer custom sizes based on your requirements. Please provide your specifications, and we will work with you to deliver the product you need. -

What is the lead time for an order?

Lead time depends on the order quantity and specific requirements. Generally, we aim to deliver within 4-6 weeks. -

Do you provide samples?

Yes, we can provide samples for testing and evaluation. Please contact us for details. -

What shipping options are available?

We offer various shipping options, including sea, air, and land freight, depending on your location and urgency.

Call to Action

Contact Us

Are you looking for high-quality zirconium pipes for chemical use? Shaanxi Peakrise Metal Co., Ltd. is here to help! With years of experience and a commitment to quality, we are your trusted partner for all your zirconium needs. Contact us today at info@peakrisemetal.com to discuss your requirements or to request a quote. Let’s work together to find the perfect solution for your project!