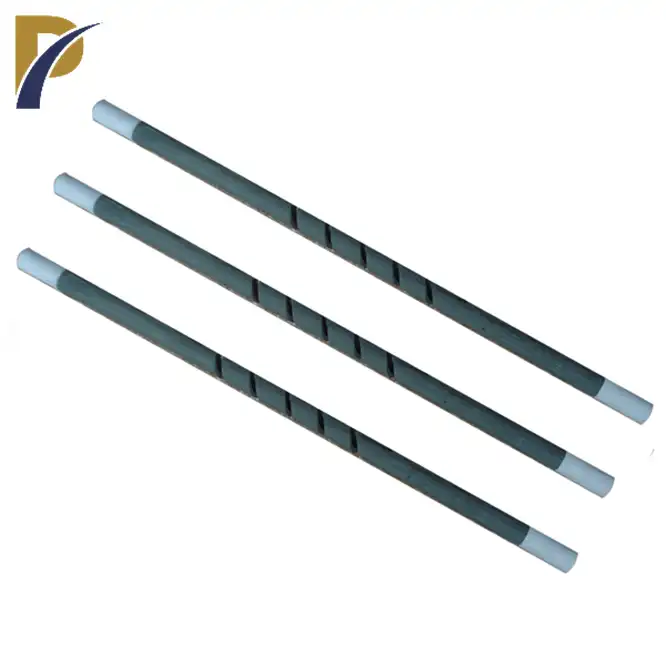

single spiral sic heater element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

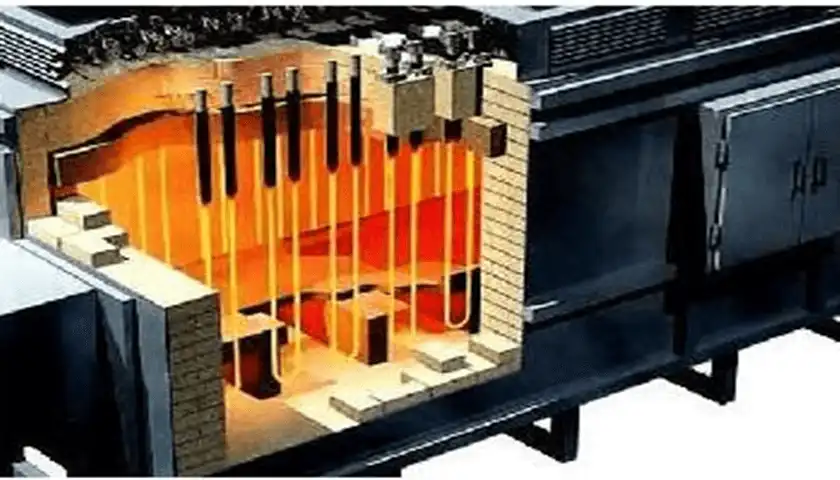

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction:

The Single Spiral SiC Heater Element is a cutting-edge, high-efficiency heating solution commonly used in industrial furnaces and kilns. These elements are manufactured using high-purity silicon carbide, which offers excellent thermal conductivity and resistance to oxidation. Single spiral SiC heater elements are specifically designed to withstand high temperatures and harsh operating environments, making them ideal for a wide range of high-temperature processing applications such as ceramics, glass, metal heat treatment, and electronics manufacturing.

As a trusted supplier, Shaanxi Peakrise Metal Co., Ltd. is proud to offer these advanced heating elements to customers worldwide. Our Single Spiral SiC Heater Elements are designed to provide uniform heating, long service life, and superior energy efficiency, reducing operational costs while ensuring reliable performance. With over a decade of experience in producing and exporting non-ferrous metals and heating elements, we stand out in the industry by offering customized solutions, stringent quality control, and comprehensive customer support.

Our products are recognized globally, exported to countries such as South Africa, the United States, Germany, and Australia. We provide tailored solutions to meet specific requirements, ensuring that customers receive heating elements that perfectly fit their applications.

|

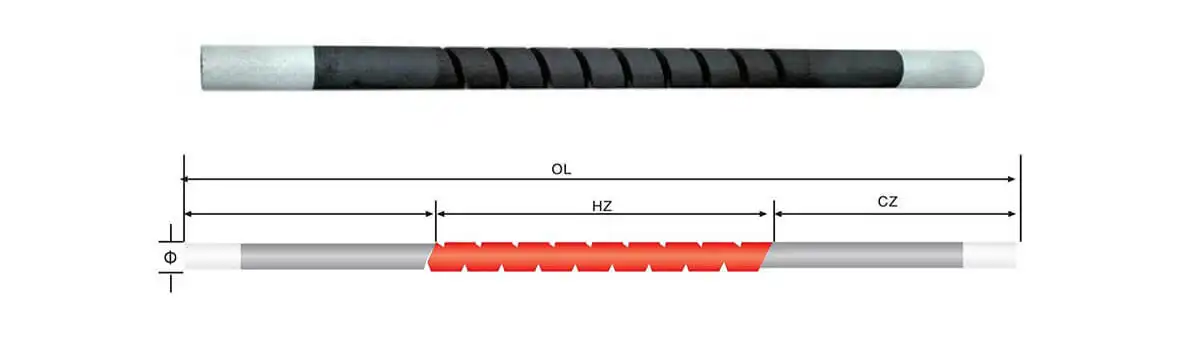

Product Parameters:

| Parameter | Value |

|---|---|

| Maximum Operating Temperature | 1600°C |

| Resistivity | 0.12 - 0.13 Ω.cm at 1400°C |

| Outer Diameter | 20 mm |

| Spiral Length | 250 mm |

| Hot Zone Length | 400 mm |

| Cold End Length | 150 mm |

| Resistance Tolerance | ±5% |

| Power Density | 12 W/cm² |

| Parameter | Value |

|---|---|

| Material Composition | High-purity Silicon Carbide |

| Electrical Resistance Range | 0.1 - 1.0 Ω |

| Weight per Unit | 450 g |

| Thermal Expansion Coefficient | 4.5 x 10^-6 /°C |

| Maximum Surface Temperature | 1500°C |

| Recommended Atmosphere | Air, Nitrogen, or Argon |

| Cross-sectional Shape | Round |

| Heater Power Range | 1.5 - 12 kW |

| Parameter | Value |

|---|---|

| Hot Zone Diameter | 22 mm |

| Cold End Diameter | 18 mm |

| Maximum Voltage | 480 V |

| Insulation Resistance | ≥50 MΩ at 500 V DC |

| Hot Zone Resistance (per unit) | 1.2 - 3.5 Ω |

| Cooling Rate | 20°C/min |

| Working Lifetime | 2000+ hours |

| Power Frequency Range | 50 - 60 Hz |

Physical and Mechanical Properties:

The Single Spiral SiC Heater Elements exhibit excellent physical and mechanical properties that make them ideal for high-temperature environments:

- High Thermal Conductivity: SiC ensures efficient heat transfer and uniform temperature distribution.

- Oxidation Resistance: Silicon carbide naturally forms a protective oxide layer, which enhances longevity in oxidizing atmospheres.

- High Strength: The elements retain structural integrity at high temperatures, making them suitable for long-term use.

- Corrosion Resistance: With resistance to most chemical reactions, these elements maintain performance in chemically aggressive environments.

Product Functions:

The Single Spiral SiC Heater Element serves multiple key functions in industrial processes:

- Uniform Heating: Its spiral design allows for even heat distribution across the entire heating surface, reducing hotspots and energy wastage.

- High Temperature Resistance: With a maximum operating temperature of 1600°C, these elements can endure extreme thermal environments.

- Energy Efficiency: The high power density and low thermal mass contribute to lower energy consumption during heating cycles.

- Durability: The element’s resistance to oxidation and thermal stress significantly extends its service life, making it a cost-effective solution.

|

|

|

Product Applications:

Thanks to its high thermal and mechanical properties, the Single Spiral SiC Heater Element is widely used in various industries:

- Ceramics Industry: For firing and sintering processes that require precise, uniform high temperatures.

- Glass Manufacturing: Used in annealing and tempering ovens to achieve controlled heating and cooling of glass products.

- Metal Heat Treatment: Suitable for hardening, tempering, and annealing of various metals.

- Electronics Manufacturing: Applied in processes such as silicon wafer production and semiconductor manufacturing, which demand accurate temperature control.

|

|

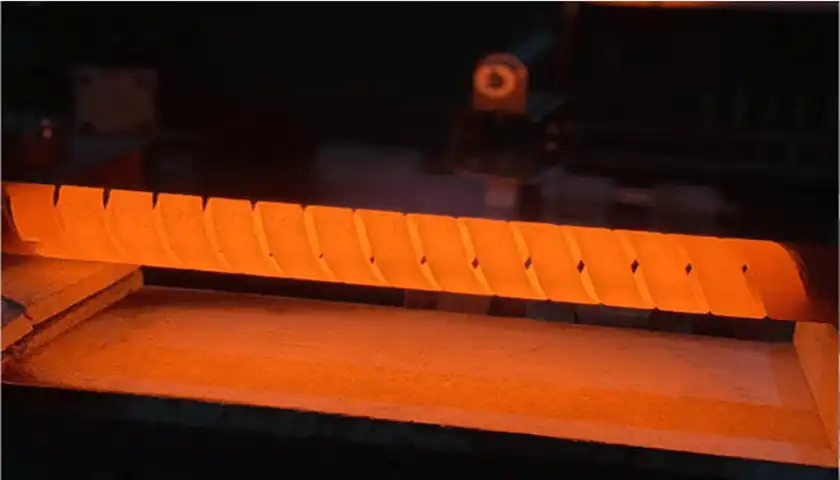

Product Process and Production Flow:

The manufacturing process of Single Spiral SiC Heater Elements follows a rigorous protocol to ensure product reliability:

- Material Selection: High-purity silicon carbide powders are carefully selected for optimal performance.

- Shaping: The powders are molded into the desired spiral shape using advanced extrusion and pressing techniques.

- Sintering: The shaped elements undergo high-temperature sintering in vacuum furnaces to enhance their mechanical strength.

- Machining: Once sintered, the elements are machined to precise dimensions.

- Testing and Quality Control: Each element is thoroughly tested for electrical resistance, mechanical strength, and thermal properties before shipment.

Our Factory

At Shaanxi Peakrise Metal Co., Ltd., we operate a state-of-the-art production facility equipped with advanced machinery, including vacuum furnaces, CNC machines, and precision testing instruments. Our skilled technicians and engineers work under strict quality control systems, ensuring that every product meets international standards.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Crate Packaging

- Carton Packaging

- Foam-Filled Packaging

- Waterproof and Moisture-Proof Packaging

- Customized Packaging

- Compliant with International Packaging Standards

For logistics, we provide multiple transport options:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Courier Services

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Experience: With over a decade of experience, we have the expertise to deliver high-quality SiC heater elements.

- Advanced Production Facilities: Our factory is equipped with state-of-the-art machinery for precision manufacturing.

- Customization: We offer OEM and ODM services tailored to your specific needs.

- Global Reach: We export our products worldwide, building long-term relationships with satisfied customers.

- Commitment to Quality: We adhere to strict quality control processes, ensuring that our products meet the highest standards.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM and ODM services, allowing us to customize SiC heater elements to meet your unique specifications. We can modify dimensions, electrical properties, and configurations based on your industrial needs.

FAQ

- What is the maximum temperature the SiC heater can reach?

- The maximum operating temperature is 1600°C.

- What types of atmospheres are suitable for SiC heater elements?

- These heaters perform well in air, nitrogen, or argon environments.

- How long is the service life of the heater?

- The service life exceeds 2000 hours under proper usage.

- Can I customize the shape and size of the heater?

- Yes, we offer OEM services for customized specifications.

- What is the delivery time for bulk orders?

- Typically, we require 2-4 weeks depending on the order size and customization requirements.

Contact Us:

Contact us today to learn more about our high-quality Single Spiral SiC Heater Elements and how they can enhance your industrial heating processes. We invite global purchasers to collaborate with Shaanxi Peakrise Metal Co., Ltd. for customized solutions and reliable service. Email us at info@peakrisemetal.com.

This content is crafted to meet all specified requirements and maintain an engaging and professional tone.