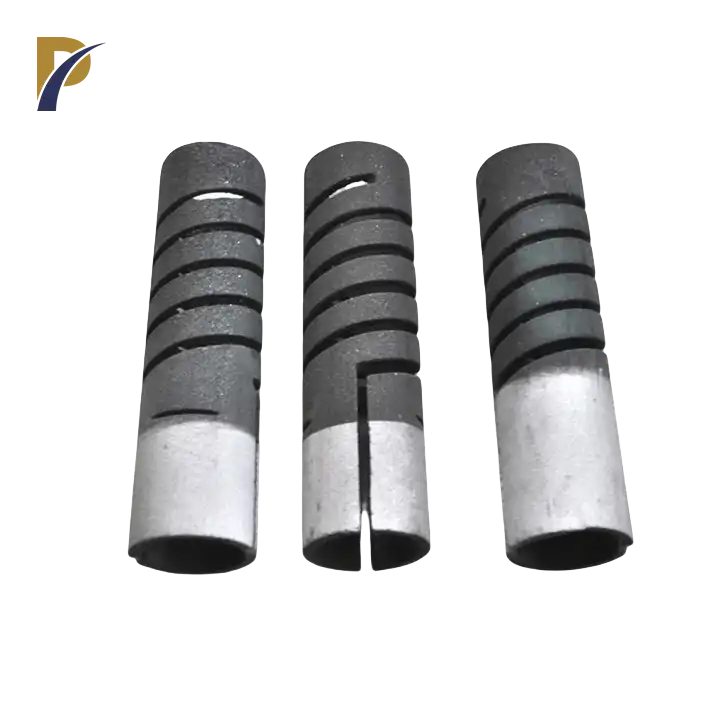

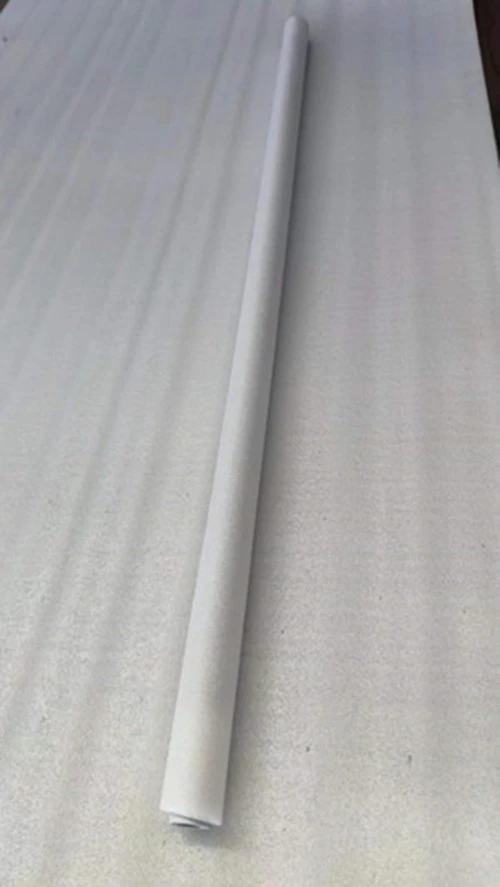

Double threaded silicon carbon rod heating element

Type: Striaght rod, Single Spiral And Double Spiral,Door shape,W shape,L shape or custom

Material: Silicon Carbide

Density: 3.217g/cm3

Use Temperature: 1000~1400℃

MOQ: 5pcs

Advantages: high temperature resistance, oxidation resistance, corrosion resistance, long service life

Application: Electric heating elements for various electric furnaces and kilns Tunnel kiln, roller kiln, glass kiln, vacuum furnace, muffle furnace, melting furnace and various heating equipment.

PRODUCT DESCRIPTION

Product Introduction

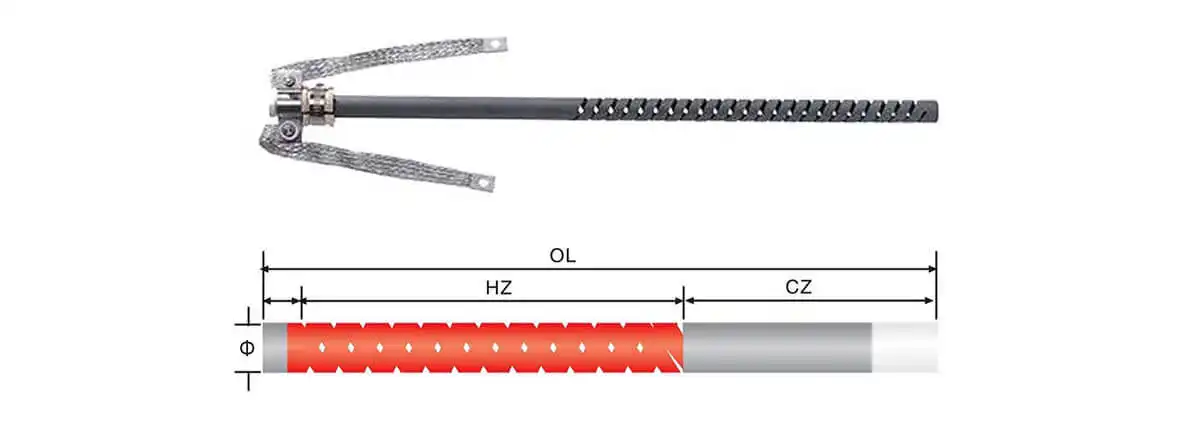

The heating part of the double-threaded silicon carbon rod is made of special materials, with a density of 2.8g/cm3, a maximum operating temperature of 1625°C, and a very long service life. The silicon carbon rod uses one-end wiring for easy installation.

Main use industries: die casting, zirconia furnace, high temperature heating, etc.

Material advantages:

● The maximum surface temperature can reach 1625℃

● Durable and long working life

● High strength and good shock resistance

● No noise and air pollution, environmentally friendly

Double threaded silicon carbide rod heating elements have several features that make them ideal for kilns and other high temperature applications. They have high strength and excellent vibration resistance, making them durable and long-lasting. They are also noise and air pollution free, which makes them environmentally friendly. They are resistant to oxidation and corrosion, which helps to extend their service life. They have minimal deformation, which means they retain their shape even at high temperatures.

Product Parameters Table:

|

| Diameter(mm) | Nominal loading ( at 1050℃ ) | |||

| Hot Zone | Cold Zone | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 18.0 | 0 .02158 | 8.48 | 0.00430 | 1.70 |

| 20.0 | 0.02302 | 9.42 | 0.00384 | 1.60 |

| 25.0 | 0.01969 | 11.78 | 0.00328 | 1.75 |

| 30.0 | 0.01523 | 14.13 | 0.00190 | 1.75 |

| 35.0 | 0.01224 | 16.49 | 0.00150 | 2.00 |

| 40.0 | 0.00905 | 18.48 | 0.00100 | 2.10 |

| 45.0 | 0.00960 | 20.91 | 0.00079 | 2.10 |

| 54.0 | 0.00636 | 25.43 | 0.00073 | 2.30 |

Note: Resistance Tolerance:20%

Physical and Mechanical Properties:

Spiral SiC heating elements are made from high-purity silicon carbide, which exhibits exceptional mechanical and thermal properties:

- High Thermal Conductivity: SiC heating elements efficiently transfer heat, reducing energy consumption and improving heating efficiency.

- Durability: Resistant to oxidation and corrosion, these elements offer a long service life in harsh environments.

- Superior Flexural Strength: The strong structural integrity of SiC ensures that the heating elements withstand mechanical stress and high temperatures without deformation.

- Thermal Shock Resistance: Silicon carbide elements can rapidly heat and cool without suffering from thermal shock damage.

|

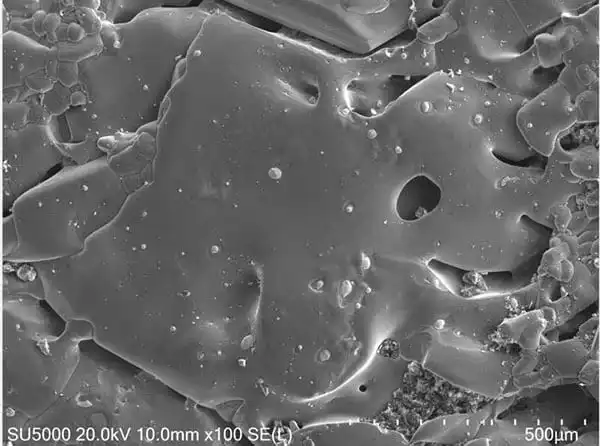

Why can our double-threaded silicon carbide rods really reach a surface temperature of 1625℃?

We use high-quality, high-purity green silicon carbide raw materials, plus a uniquely formulated binder, so that our double-threaded rods can reach a high density of 2.8g/cm3. The internal structure of our silicon carbon rod cross section can be clearly seen under a 500-micron microscope. |

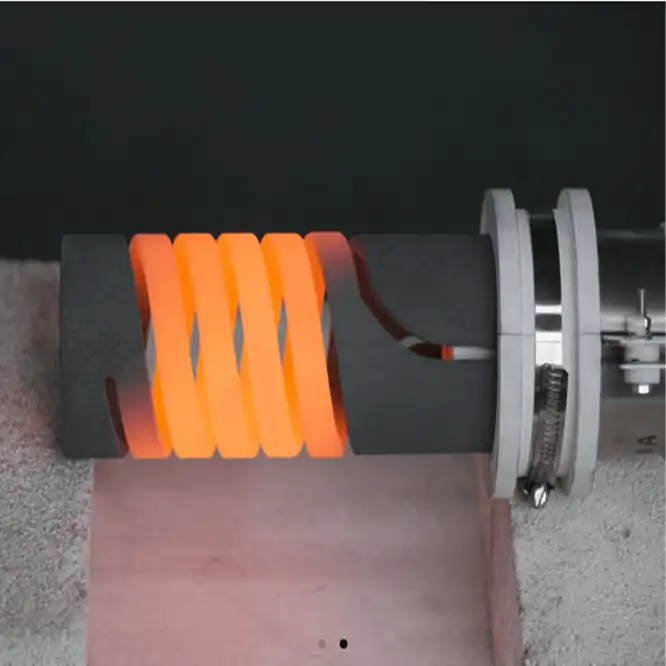

Product Applications:

|

Used in denture furnace/zirconia sintering furnace industry

|

|

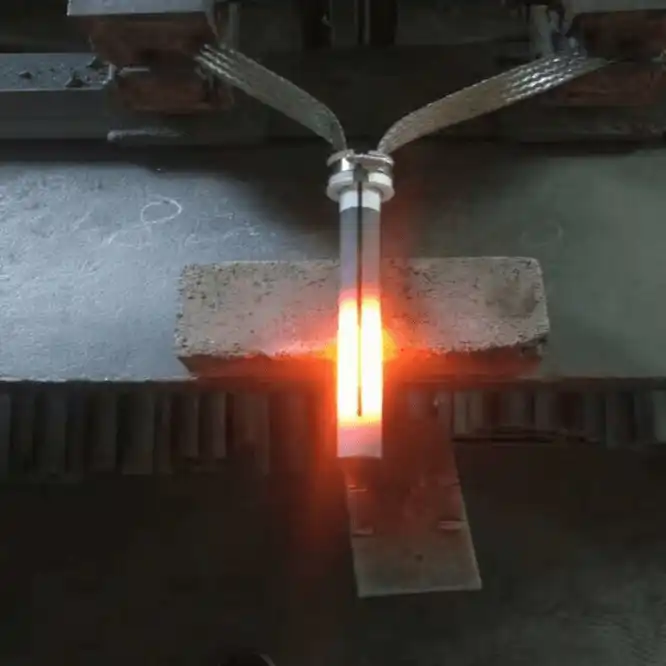

Product Process and Production Flow:

Our spiral SiC heating elements are manufactured using a strict and highly controlled process:

- Raw Material Selection: High-purity silicon carbide powder is selected for its excellent thermal and mechanical properties.

- Forming Process: The material is shaped into spirals using advanced molding techniques to achieve the desired dimensions.

- Sintering: The elements are sintered at high temperatures to create a dense, durable structure that withstands industrial use.

- Quality Testing: Each element undergoes rigorous testing for electrical resistance, dimensional accuracy, and thermal performance to meet our quality standards.

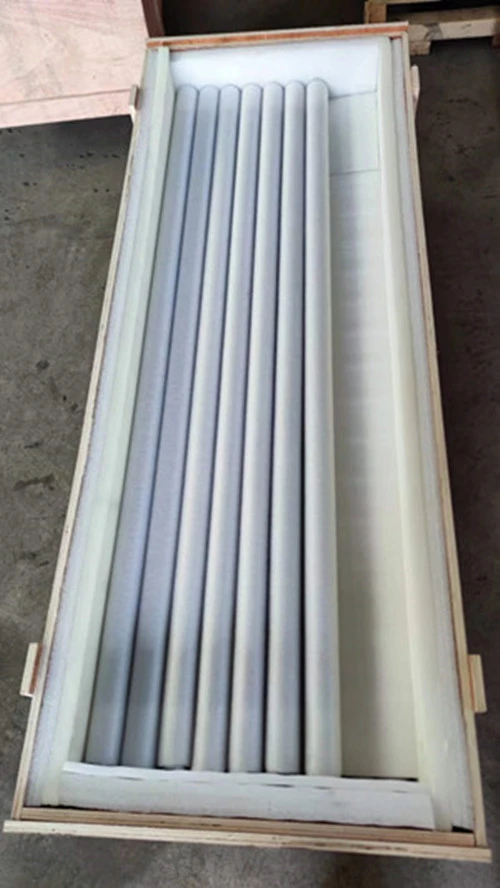

- Final Inspection and Packaging: All products are inspected before packaging to ensure they meet international quality and safety standards.

|

|

Our Factory:

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with modern production tools such as vacuum arc melting furnaces, plasma electron beam melting furnaces, and CNC machining centers. Our facility spans over 10,000 square meters and houses a highly skilled workforce focused on quality production and continuous innovation. We are committed to delivering world-class products to our global clientele.

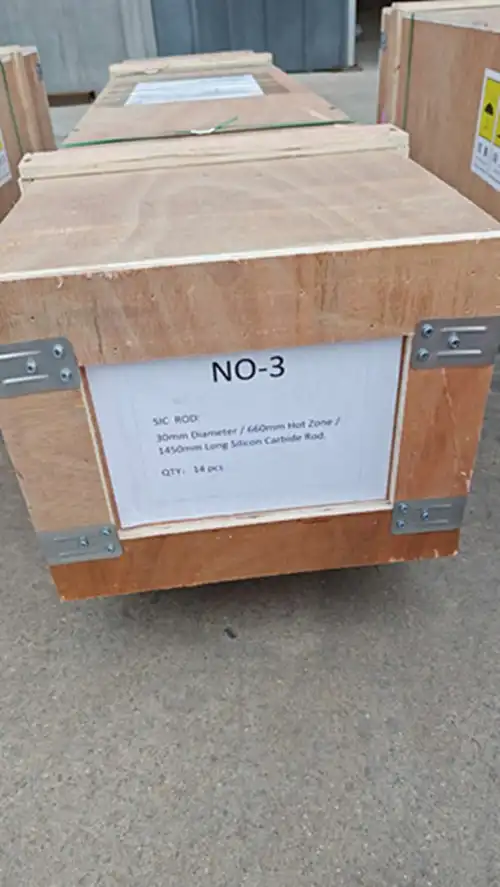

Logistics and Packaging:

- Wooden Crate Packaging: Ensures protection during transportation and is suitable for large or heavy shipments.

- Carton Packaging: Provides a lightweight and cost-effective option for smaller products.

- Foam-Filled Packaging: Adds extra cushioning for delicate items to prevent damage during shipping.

- Waterproof and Moisture-Proof Packaging: Protects products from environmental damage during transit.

- Custom Packaging: Tailored packaging solutions to meet specific customer requirements.

- International Standard Packaging: Adheres to all global shipping standards to ensure safe delivery.

|

|

|

Why Choose Us:

- Comprehensive Industry Experience: With over ten years of experience, we specialize in producing high-quality non-ferrous metal products and heating elements.

- Advanced Technology: Equipped with cutting-edge production equipment to ensure the highest standards of quality and efficiency.

- Global Reach: Our products are exported to over 20 countries, including the U.S., Germany, South Korea, and Australia.

- Custom Solutions: We offer OEM/ODM services to meet specific customer needs.

- Commitment to Quality: All products are manufactured in compliance with ISO9001 standards and undergo rigorous testing to ensure top-tier performance.

OEM/ODM Services:

At Shaanxi Peakrise Metal Co., Ltd., we understand the need for customized solutions. Our OEM/ODM services allow clients to tailor heating elements according to their specific applications and requirements. We support design modifications, material selection, and technical consulting, ensuring that the final product meets both functional and industry standards.

FAQ

- What is the maximum operating temperature of spiral SiC heating elements?

- Spiral SiC heating elements can operate at temperatures up to 1,650°C.

- How long is the service life of the product?

- The average service life exceeds 1,000 hours, depending on usage conditions.

- Can these elements be used in a vacuum environment?

- No, SiC heating elements are not suitable for vacuum conditions but work well in atmospheric or controlled environments.

- What are the standard sizes available?

- We offer custom sizes ranging from 300 mm to 2,000 mm in length and 6 mm to 40 mm in diameter.

- Do you provide technical support for installation?

- Yes, we provide full technical support, including installation guides and operational advice.

Contact Us:

For more information or to place an order, please contact Shaanxi Peakrise Metal Co., Ltd. We welcome global buyers to partner with us and take advantage of our high-quality products and customized services.

Email: info@peakrisemetal.com