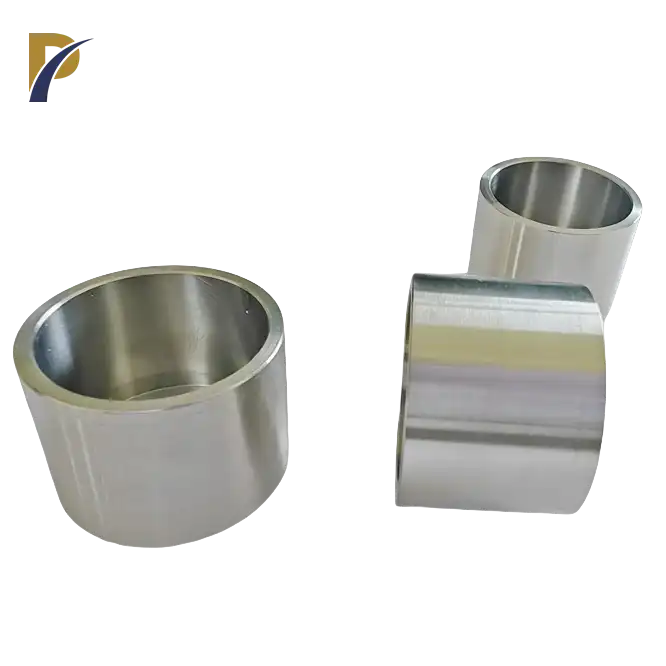

Custom Zirconium Crucibles for ICP-OES Laboratory Purification Zirconium Crucible Zr702 Zr Crucible

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Custom Zirconium Crucibles for ICP-OES Laboratory Purification Zirconium Crucible Zr702 Zr Crucible | Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. proudly offers custom zirconium crucibles for ICP-OES Laboratory Purification, a vital component in modern metallurgy and high-temperature material processing. Zirconium crucibles are renowned for their superior corrosion resistance, high melting point, and excellent chemical stability, making them ideal for use in a range of demanding environments such as vacuum or inert gas atmospheres. With our custom zirconium crucibles, clients in industries like aerospace, medical technology, and high-precision casting can depend on exceptional material performance, even under extreme conditions.

Our team specializes in manufacturing zirconium crucibles tailored to specific casting applications, ensuring the highest levels of product precision, purity, and performance. At Shaanxi Peakrise Metal Co., Ltd., we’ve built a reputation for producing high-quality custom crucibles that meet industry standards, ensuring reliable performance, durability, and efficiency. Whether you need zirconium crucibles for research and development or full-scale industrial production, our advanced manufacturing capabilities can deliver the perfect solution for your specific needs.

As a leading supplier of custom zirconium crucibles for casting, we understand the complex requirements of this niche. Our company has been at the forefront of producing high-performance zirconium crucibles, offering customized solutions to meet our clients' exact specifications. Our global customers trust us to deliver consistent, high-quality zirconium products that provide reliability and longevity in the most challenging environments.

|

Product Specifications

| Name: | Custom Zirconium Crucibles for ICP-OES Laboratory Purification Zirconium Crucible Zr702 Zr Crucible |

| Material: | Zirconium & Zirconium alloy |

| Grade: | Zr702,Zr705,RO60001,RO60901 |

| Density: | 6.51g/cm3 |

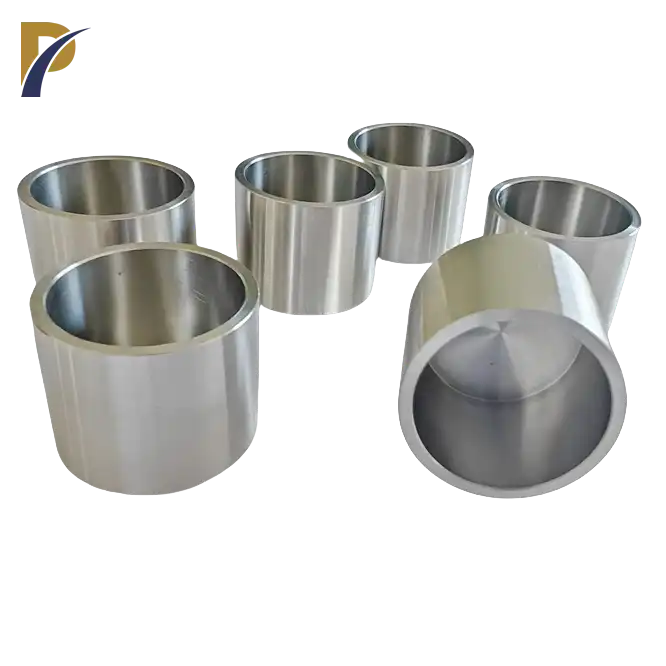

| Shape: | Crucible |

| Type: | Low form zirconiu crucible, flanged rims zirconium crucible,straight wall zirconium crucible, tapered zirconium crucible, Cylindrical zirconium crucible |

| Volume: | 5ml,10ml,15ml,20ml,25ml,30ml,35ml,40ml,45ml,50ml etc, |

| Custom | Yes, process as per customer's drawing. |

Physical and Chemical Properties

- Melting Point: 1855°C

- Boiling Point: 4409°C

- Density: 6.52 g/cm³

- Thermal Conductivity: 22.6 W/m·K

- Corrosion Resistance: Resistant to acids and alkalis, including hydrochloric and sulfuric acids

- Reactivity: Stable in vacuum and inert gas environments, making it ideal for use in extreme conditions such as high-temperature casting processes

Product Functions

- High Corrosion Resistance: Zirconium crucibles resist corrosion from strong acids and alkalis, making them suitable for harsh chemical environments.

- Superior Thermal Stability: With a high melting point, zirconium crucibles can withstand extreme temperatures, making them ideal for high-temperature casting applications.

- Chemical Inertness: Zirconium’s chemical stability ensures that it doesn’t react with molten metals, providing a pure and contamination-free casting process.

- Durability: Thanks to its strong resistance to wear and tear, zirconium crucibles offer longer lifespans in aggressive industrial settings.

- Precision Engineering: Customizable in size and shape, these crucibles can be designed to fit specific industrial applications, ensuring efficiency and effectiveness in casting processes.

|

|

|

Product Applications

- Aerospace Industry: Zirconium crucibles are used in the casting of high-precision components for jet engines and other aerospace parts that require materials capable of withstanding extreme temperatures.

- Medical Devices Manufacturing: Zirconium's biocompatibility makes it ideal for casting implants and medical tools, offering precision and safety in the medical field.

- Nuclear Energy: Thanks to its low neutron absorption properties, zirconium crucibles are commonly used in nuclear energy applications where contamination prevention is critical.

- Laboratory Research: In high-temperature experiments, zirconium crucibles are favored for their ability to maintain stability in extreme environments, ensuring accurate and uncontaminated results.

- Specialty Casting: The precision and purity of zirconium make it a key material in specialty metal casting industries, including electronics, jewelry, and fine arts.

|

|

Manufacturing Process and Production Flow

Our custom zirconium crucibles are produced using a stringent and meticulous manufacturing process designed to maintain material integrity and ensure precise dimensions:

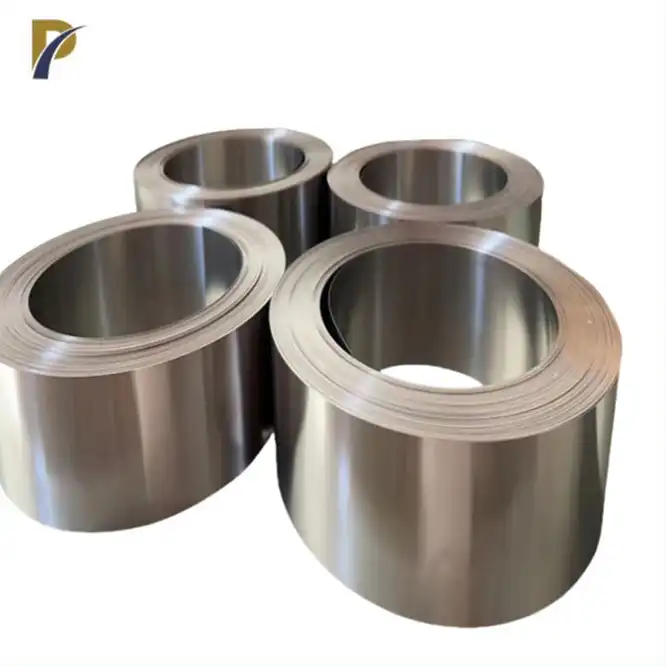

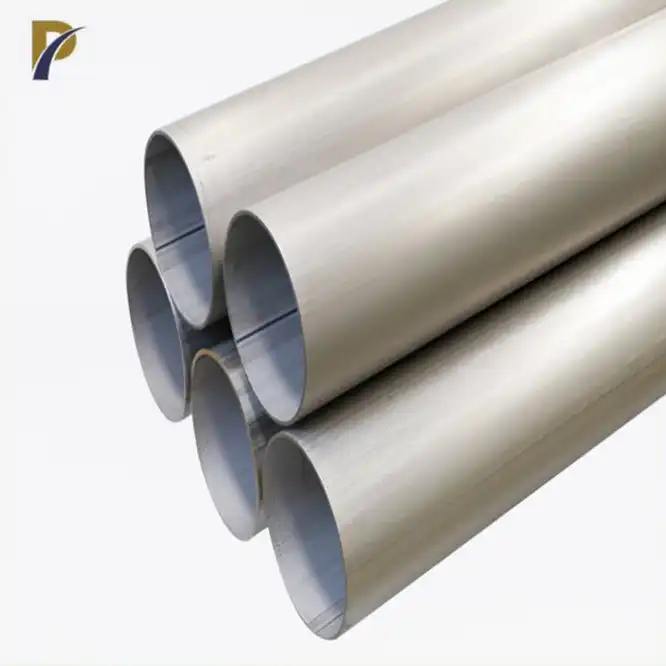

- Raw Material Selection: We use only high-purity zirconium (99.5% minimum) sourced from reliable suppliers to guarantee product quality.

- Vacuum Melting: The raw zirconium is melted in a vacuum arc furnace to ensure its purity and uniformity, eliminating any impurities that may affect performance.

- Forming: The molten zirconium is shaped into crucibles using precision molds, ensuring uniform thickness and dimensions.

- Annealing: The formed crucibles are annealed in a vacuum furnace to relieve any stresses from the manufacturing process, enhancing durability.

- Surface Treatment: The crucibles undergo polishing and finishing to ensure smooth surfaces, reducing contamination risks during casting.

- Final Inspection: Each crucible undergoes rigorous quality control checks, including dimensional accuracy, purity analysis, and surface finish inspection, ensuring only the highest quality products leave our facility.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Experience: Shaanxi Peakrise Metal Co., Ltd. has over a decade of experience in producing and supplying non-ferrous metal products, including high-performance zirconium crucibles.

- Advanced Manufacturing Equipment: Our state-of-the-art production facilities include vacuum arc melting furnaces, CNC machines, and advanced surface treatment tools, ensuring the highest quality standards.

- Customization: We offer a full range of custom services, from material purity to shape and size, tailored to meet the unique needs of your casting operations.

- Global Reach: Our products are trusted by customers in over 20 countries, including the United States, Germany, South Korea, and Australia, with long-standing partnerships and excellent customer feedback.

- Strict Quality Control: Our manufacturing processes are backed by strict quality management systems, ensuring consistent, high-quality products.

OEM/ODM Services

At Shaanxi Peakrise Metal Co., Ltd., we understand that every client’s needs are different. That’s why we offer comprehensive OEM/ODM services for custom zirconium crucibles. Whether you need a specific size, shape, or material composition, we can accommodate your requirements. Our engineers work closely with you to design and manufacture crucibles that fit seamlessly into your casting processes. We offer flexible production capabilities, ensuring rapid delivery and strict adherence to your project timelines.

|

|

Packaging

- Wooden Crates: Heavy-duty wooden crates are used for larger orders to ensure secure transportation and prevent damage.

- Cardboard Boxes: For smaller orders, crucibles are packaged in sturdy cardboard boxes.

- Foam Padding: All packages include foam padding to prevent movement and impact during shipping.

- Waterproof and Moisture-proof Packaging: Our packaging materials are designed to protect products from moisture and environmental damage.

- Custom Packaging: We also offer custom packaging options to meet specific customer requirements, ensuring safe and secure delivery.

Logistics

- Sea Freight: Ideal for bulk orders, offering cost-effective global shipping.

- Air Freight: Fast and reliable air freight for urgent orders, delivering products quickly to your location.

- Land Transport: Available for regional deliveries, ensuring timely arrival and minimal transit time.

- Multimodal Transport: We can combine multiple transport methods to optimize delivery times and costs.

- Courier Services: For small orders or urgent needs, we offer express courier services for quick and efficient delivery.

|

|

|

|

|

|

|

|

|

|

FAQs

-

What is the purity of your zirconium crucibles?

Our zirconium crucibles have a minimum purity of 99.5%, ensuring high performance in high-temperature applications. -

Can you customize the dimensions of the crucibles?

Yes, we offer full customization options, including diameter, height, and wall thickness, to meet your specific requirements. -

What industries are your zirconium crucibles suitable for?

Our crucibles are ideal for aerospace, medical, nuclear energy, and specialty casting applications. -

What is the typical lead time for custom orders?

The lead time for custom orders typically ranges from 4 to 6 weeks, depending on the complexity and quantity. -

Do you provide sample crucibles for testing?

Yes, we can provide samples upon request to ensure that our products meet your performance expectations before placing a bulk order.

Contact Us – Take the Next Step!

Are you ready to take your casting operations to the next level with high-quality, custom zirconium crucibles? Contact Shaanxi Peakrise Metal Co., Ltd. today to discuss your requirements and learn how we can help. Our team of experts is here to guide you through the selection process and offer tailored solutions that fit your specific needs. Email us at info@peakrisemetal.com or call us to get started on your custom order today!

By focusing on technical expertise, offering tailored solutions, and emphasizing the quality and reliability of our products, this content aims to attract and convert potential customers, while also adhering to SEO best practices.