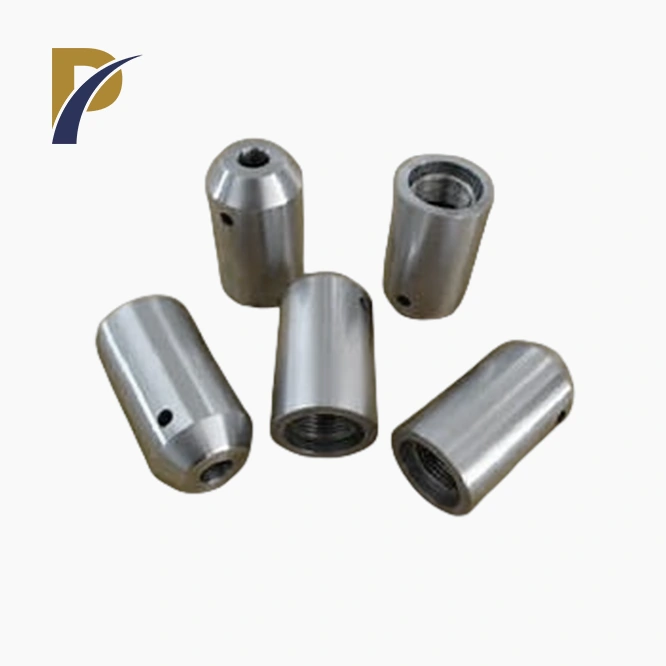

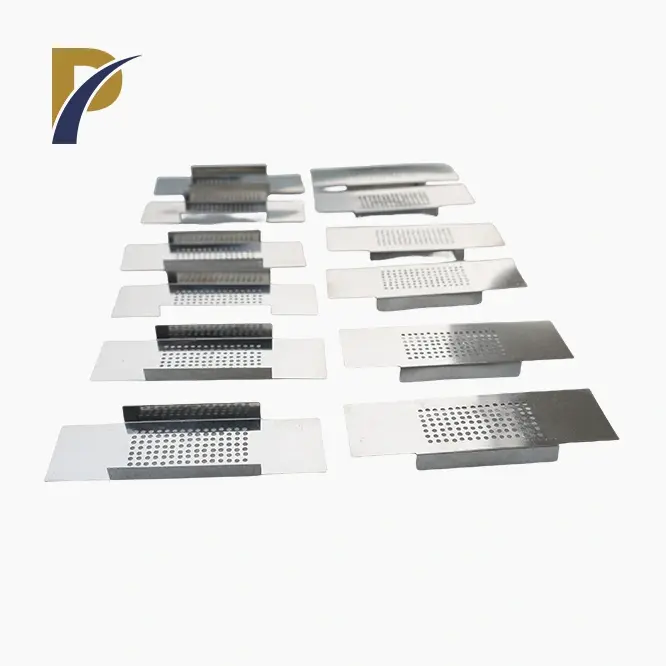

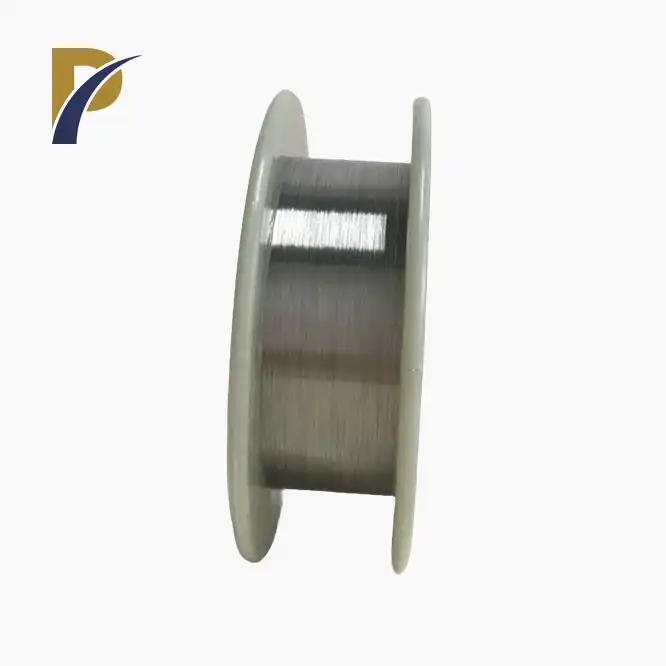

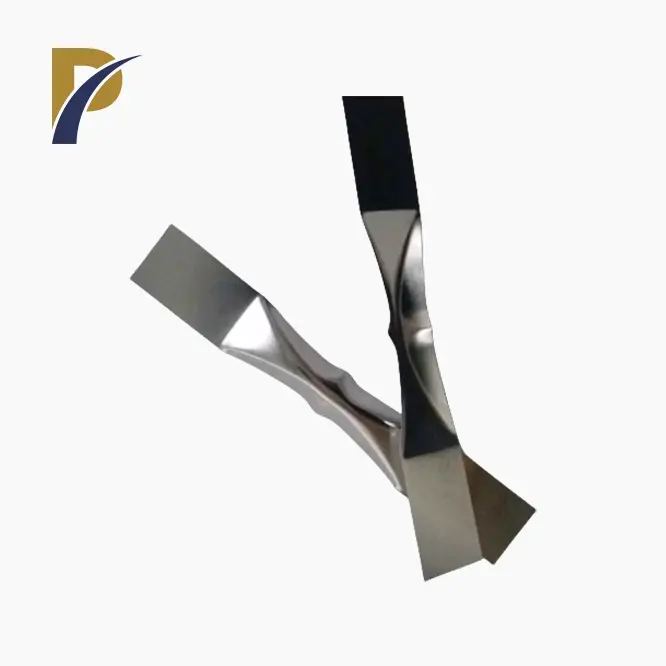

Zirconium Specialty Machined Parts

Model Number:Custom

Minimum Order Quantity:1pc

Price:Negotiate

Packaging Details:Plywood case

Delivery Time:5~7days

Payment Terms:T/T

Supply Ability:50ton/month

PRODUCT DESCRIPTION

Zirconium Specialty Machined Parts - Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

Zirconium Specialty Machined Parts are critical components in industries that require extreme resistance to corrosion, high temperatures, and harsh environments. Known for its superior strength-to-weight ratio and exceptional resistance to acids, alkalis, and other corrosive materials, zirconium is widely used in the chemical processing, aerospace, and nuclear industries. At Shaanxi Peakrise Metal Co., Ltd., we specialize in the manufacturing and supply of high-precision, custom-made zirconium parts that meet the stringent demands of these industries.

Our zirconium machined parts are tailored to suit the needs of our global clients, ensuring that every component offers optimal performance and reliability. Leveraging over a decade of experience, Shaanxi Peakrise Metal is a leader in non-ferrous metal production, offering cutting-edge solutions that cater to industries seeking both high-quality materials and cost-effective production processes. We take pride in our ability to provide zirconium parts that are meticulously crafted and engineered to withstand the harshest conditions, helping our clients achieve superior product performance in their respective fields.

With state-of-the-art equipment and a deep understanding of zirconium’s properties, we deliver products that meet the highest international standards. Our parts are extensively tested to ensure durability, precision, and longevity, making us the go-to supplier for companies seeking reliable zirconium machined components.

Product Specifications

| Property | Value |

|---|---|

| Density | 6.51 g/cm³ |

| Melting Point | 1855°C |

| Tensile Strength | 330 MPa |

| Hardness (Vickers) | 320 HV |

| Thermal Conductivity | 22 W/m·K |

| Property | Value |

|---|---|

| Elastic Modulus | 88 GPa |

| Electrical Resistivity | 40.3 nΩ·m |

| Oxidation Resistance | Up to 500°C |

| Purity | ≥ 99.5% |

| Grain Size | Customizable |

|

|

|

|

|

|

|

|

|

Product Specifications

| Parameter | Value | Units |

|---|---|---|

| Zirconium Purity | 99.95% | |

| Density | 6.51 | g/cm³ |

| Melting Point | 1855 | °C |

| Tensile Strength | 330 - 680 | MPa |

| Thermal Conductivity | 22.7 | W/m·K |

| Maximum Working Temperature | 850 | °C |

Physical and Chemical Properties

Zirconium is renowned for its exceptional corrosion resistance, especially in acidic environments. Its strong mechanical properties, combined with its resistance to high temperatures, make it an ideal material for applications in harsh environments. Some key properties include:

- High Melting Point: Zirconium has a melting point of 1855°C, allowing it to perform under extreme thermal conditions.

- Low Thermal Expansion: The material's low thermal expansion helps in maintaining stability under fluctuating temperatures.

- Corrosion Resistance: Zirconium exhibits excellent resistance to many chemicals, making it perfect for industries like chemical processing and pharmaceuticals.

- Biocompatibility: Zirconium is non-toxic and exhibits excellent compatibility with biological systems, making it suitable for medical and dental applications.

| Grade | Element composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.20 | -- | 0.005 | 0.025 | 0.05 | -- | 0.16 |

| R60703 | 98 | 4.5 | -- | -- | --0.005 | 0.025 | -- | -- | -- |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | -- | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

| R60706 | 95.5 | 4.5 | 0.2 | -- | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

Product Functions

- Corrosion Resistance: Zirconium's ability to resist strong acids and alkalis makes it a preferred material for use in chemical processing industries.

- Heat Resistance: Zirconium maintains its integrity at high temperatures, providing reliable performance in high-heat applications such as aerospace and nuclear reactors.

- Biocompatibility: Thanks to its biocompatibility, zirconium is widely used in medical implants, where material safety and durability are paramount.

- Electrical Conductivity: Zirconium’s electrical properties make it useful in electrical components that require both strength and conductivity.

- Custom Machinability: With superior machinability, zirconium can be tailored into precise shapes and components, meeting the needs of various industries.

Heat Resistance:

Excellent Conductivity

Corrosion Resistance

Product Applications

- Chemical Processing: Zirconium's superior corrosion resistance makes it ideal for use in reactors, heat exchangers, and piping systems where strong acids or alkalis are present.

- Aerospace Industry: Due to its high strength-to-weight ratio and heat resistance, zirconium machined parts are critical in aerospace components, especially those subjected to extreme temperatures.

- Nuclear Energy: Zirconium’s low absorption of neutrons makes it an essential material for nuclear reactor components, including cladding for fuel rods.

- Medical Implants: Zirconium’s biocompatibility allows its use in dental implants, bone screws, and other medical devices that require non-toxic materials.

- Defense Industry: Zirconium’s resistance to heat and corrosion makes it suitable for use in military applications, including high-performance weapon systems and vehicles.

|

|

Manufacturing Process and Production Flow

The manufacturing process of zirconium machined parts at Shaanxi Peakrise Metal Co., Ltd. involves several key stages:

- Material Selection: We source high-purity zirconium to ensure the best possible performance and reliability.

- Precision Machining: Using advanced CNC machines and precision tools, we craft custom zirconium parts to the exact specifications required by our clients.

- Heat Treatment: Components are heat-treated to enhance their strength and durability, especially for high-temperature applications.

- Quality Control: Every zirconium part undergoes rigorous testing, including dimensional accuracy, mechanical strength, and corrosion resistance tests.

- Surface Finishing: Depending on the application, parts are finished to ensure smoothness, reduce friction, or enhance corrosion resistance.

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Experience: With over a decade of experience, we are experts in producing high-quality zirconium and non-ferrous metal products.

- Advanced Technology: Our factory is equipped with state-of-the-art machinery, including vacuum arc melting furnaces, CNC machines, and plasma welding stations.

- Global Reach: We supply high-quality zirconium parts to clients in the United States, South Korea, Germany, and many other countries.

- Strict Quality Control: All products are thoroughly tested to meet international standards such as ASTM B551 and ISO 9001.

- Customization: We offer tailor-made solutions to meet the unique needs of each client, ensuring that every part performs as required.

OEM/ODM Service

At Shaanxi Peakrise Metal Co., Ltd., we offer comprehensive OEM/ODM services. Whether you need standard zirconium parts or highly customized solutions, our team is ready to meet your exact specifications. We work closely with our clients to understand their requirements and provide cost-effective, high-quality solutions tailored to their needs.

|

|

Packaging

- Wooden Crate Packaging: For large, heavy zirconium parts that require maximum protection during transport.

- Cardboard Box Packaging: Used for smaller parts, ensuring secure packaging with reduced shipping costs.

- Foam Padding: Ensures parts are protected from shocks and vibrations during transportation.

- Waterproof and Moisture-Proof Packaging: Essential for parts being shipped to humid or rainy regions.

- Custom Packaging: Available upon request to meet the specific needs of clients and shipping requirements.

- International Standard Packaging: All packaging adheres to international shipping standards, ensuring safe and secure delivery worldwide.

Logistics

- Sea Freight: Cost-effective for large shipments over long distances.

- Air Freight: Fast and reliable for urgent deliveries.

- Land Transport: Used for deliveries within close proximity.

- Multimodal Transport: Combining various methods of transport to reduce costs and improve efficiency.

- Courier Services: Ideal for smaller, time-sensitive deliveries.

|

|

|

|

|

|

|

|

|

|

FAQs

-

What is the lead time for zirconium parts?

- Lead times vary depending on the complexity of the part and order size. Generally, it takes 2-4 weeks for production and delivery.

-

Do you provide customization for zirconium parts?

- Yes, we offer full customization services, including specific dimensions, surface finishes, and tolerances.

-

What standards do your zirconium parts comply with?

- Our zirconium parts comply with ASTM B551 and ISO 9001 standards.

-

What industries do you supply to?

- We supply to industries such as aerospace, nuclear energy, chemical processing, and medical device manufacturing.

-

How do you ensure the quality of your products?

- We have a strict quality control process, including material testing, dimensional inspections, and performance evaluations.

Call to Action - Contact Us

Ready to take your projects to the next level with high-quality Zirconium Specialty Machined Parts? Contact Shaanxi Peakrise Metal Co., Ltd. today! We are eager to partner with you and provide the best solutions for your industry. Reach out to us at info@peakrisemetal.com for more information or to request a quote. Let's create something extraordinary together!

YOU MAY LIKE

-

VIEW MORE35ml zirconium crucible

VIEW MORE35ml zirconium crucible -

VIEW MOREsic rod heater element

VIEW MOREsic rod heater element -

VIEW MORE99.95% white color molybdenum wires bright molybdenum wire

VIEW MORE99.95% white color molybdenum wires bright molybdenum wire -

VIEW MOREmolybdenum electrodes for glass furnace

VIEW MOREmolybdenum electrodes for glass furnace -

VIEW MOREmolybdenum vacuum boat

VIEW MOREmolybdenum vacuum boat -

VIEW MOREtungsten evaporation boat

VIEW MOREtungsten evaporation boat -

VIEW MOREtantalum ro5200 wires

VIEW MOREtantalum ro5200 wires -

VIEW MOREcustom tantalum rings

VIEW MOREcustom tantalum rings