molybdenum high temperature alloy tzm foil

Diameter: 2-200mm

Length: 10-250mm

Density: 10.22g·cm-3

Elongation: 20%

Melting Point : 2617℃

Yield Strength: 560~1150MPa

Tensile Strength: 685MPa

Resistivity: (5.3~5.5)X10-8 Ω·m

Standard: ASTM B387

PRODUCT DESCRIPTION

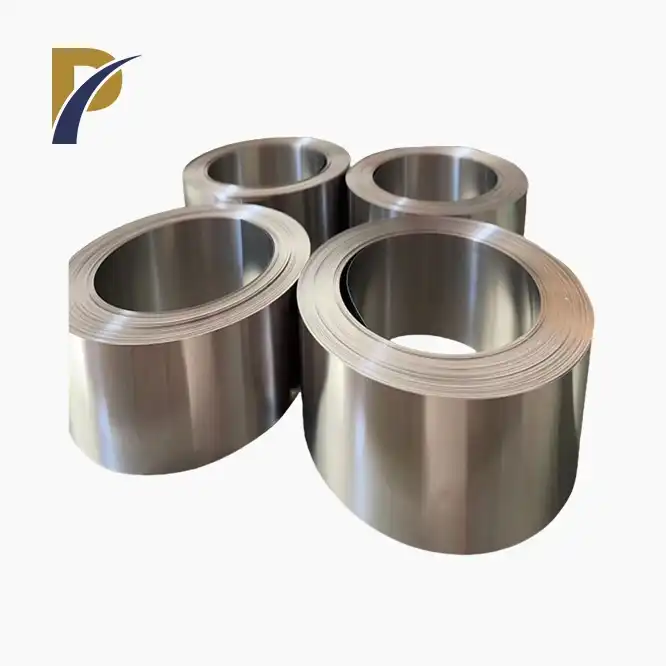

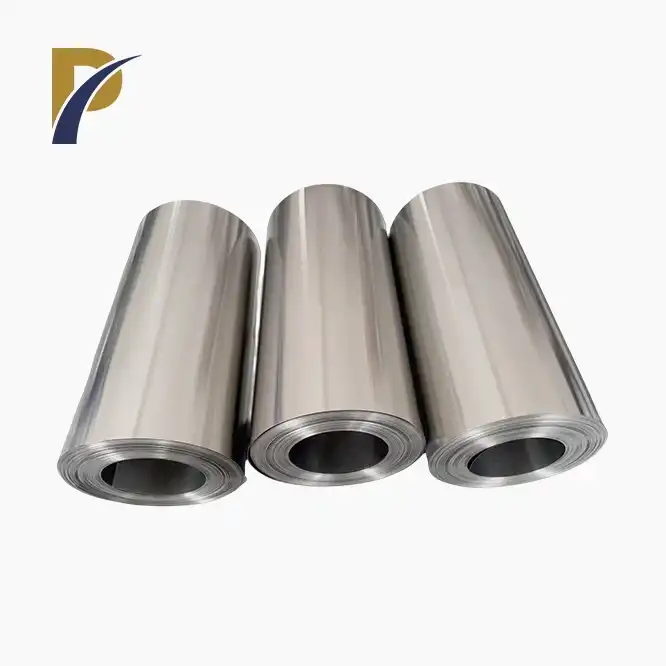

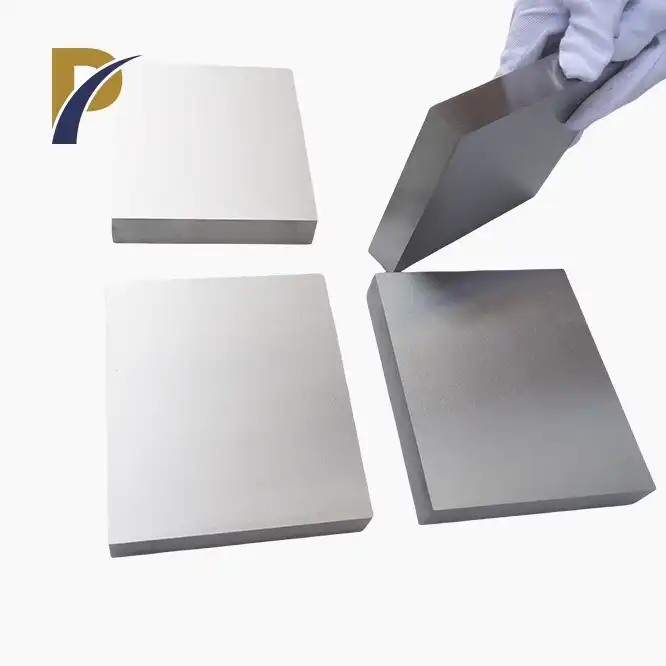

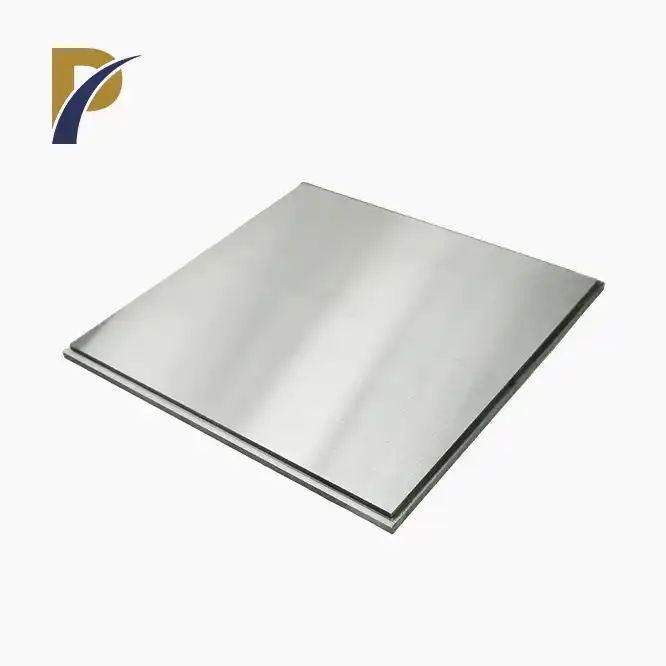

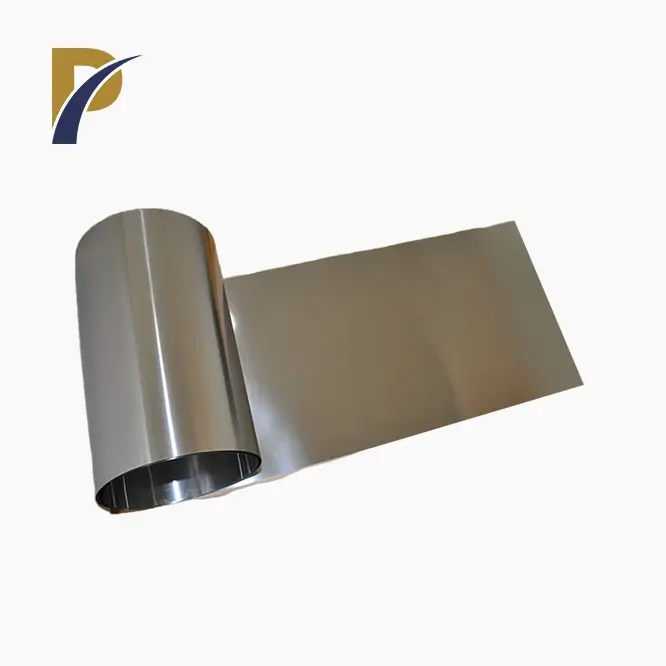

Product Introduction: Molybdenum High Temperature Alloy TZM Foil

Molybdenum high-temperature alloy TZM foil is a superior material used in various high-temperature applications. Known for its exceptional mechanical strength, high thermal conductivity, and resistance to oxidation, TZM alloy (Titanium-Zirconium-Molybdenum) is an ideal choice for demanding environments, including aerospace, nuclear industries, and heat treatment processes. As a leading supplier, Shaanxi Peakrise Metal Co., Ltd. specializes in producing high-quality molybdenum high-temperature alloy TZM foil. With our extensive experience in manufacturing and exporting non-ferrous metals, we ensure that our products meet the highest industry standards, offering reliability and performance to our global customers. Our focus on precision engineering and quality control makes us a trusted partner for companies seeking durable and efficient solutions for their high-temperature needs.

At Shaanxi Peakrise Metal Co., Ltd., we are committed to delivering top-notch TZM foil that meets specific requirements for thickness, surface finish, and mechanical properties. Whether you need the foil for thermal management systems, advanced heat shielding, or components in high-stress environments, our TZM foil offers unmatched performance. Our products are used globally in industries like defense, energy, and electronics, where the material's unique properties are critical. With our in-house R&D, advanced production capabilities, and stringent quality testing, we can provide customized solutions tailored to your project needs. We pride ourselves on our ability to offer high-quality products with fast turnaround times, making us your preferred TZM foil supplier.

Product Parameters

molybdenum high temperature alloy tzm foil

density: 10.2g/cm3

Grade: Mo 1 Mo2 Mo361 Mo364

Purity: 99.95%,99.97%

Standard :ASTM B386 ,ASME SB386

Size:Thickness(0.025mm---3mm)*width(10-300mm)*Lmm

Appearance: Surface can be supplied in a mirror or matte finish dependent upon thickness and width parameters.

Condition: Vacuum Anneal and un-annealed.

| Element | Si | Mn | Ni | Cu | V | Zr | O | P | Fe | Mg |

| Concentration(%) | 0.002 | 0.0009 | 0.0008 | 0.0018 | 0.013 | 0.086 | 0.32 | 0.001 | 0.0011 | 0.0015 |

| Element | Al | Ti | Ca | C | N | |||||

| Concentration(%) | 0.001 | 0.5 | <0.001 | 0.012 | 0.0022 | |||||

| Purity(Metallic Base) Mo≥99.06%(TZM) | ||||||||||

|

|

|

Physical and Mechanical Properties

Molybdenum TZM foil has remarkable physical and mechanical properties that make it ideal for high-stress, high-temperature applications:

- High Strength and Durability: TZM foil maintains excellent tensile strength and resistance to deformation at elevated temperatures.

- Oxidation Resistance: The alloy offers substantial resistance to oxidation when used in inert or vacuum environments, extending the lifespan of the material.

- Thermal Conductivity: The high thermal conductivity of TZM ensures efficient heat transfer in applications requiring precise temperature control.

- Low Coefficient of Thermal Expansion: The material's low expansion rate minimizes dimensional changes during thermal cycling, making it stable for high-precision applications.

- Creep Resistance: It exhibits outstanding resistance to creep, even at temperatures exceeding 1000°C.

|

Elongation /% |

Elastic Modulus /GPa |

Yield Strength /MPa |

Tensile Strength /MPa |

Fracture Toughness /(MP·m1/2) |

|

<20 |

320 |

560~1150 |

685 |

5.8~29.6 |

Product Applications

- Aerospace Industry: TZM foil is commonly used in the aerospace industry for manufacturing heat shields and nozzles in rockets and jet engines, where high thermal and mechanical stability is required.

- Nuclear Power Plants: Due to its resistance to radiation and low thermal expansion, TZM foil is suitable for high-temperature reactor parts in nuclear power plants.

- Medical Technology: TZM's biocompatibility allows its application in medical devices that must operate in high-temperature environments, such as X-ray machines and radiation equipment.

- Industrial Furnaces: TZM foil's excellent heat resistance makes it ideal for lining industrial furnaces and high-temperature kilns, ensuring longevity in extreme conditions.

- Energy Sector: The foil's thermal management properties allow it to be used in advanced energy storage and conversion systems.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility with advanced equipment, including vacuum arc furnaces, hot rolling mills, and annealing furnaces. Our team of skilled engineers and technicians ensures that every step of the production process is meticulously controlled to guarantee the highest quality. We maintain a large inventory of raw materials and finished products, enabling us to meet both small and large order requirements quickly.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Packaging Options:

- Wooden Crates

- Carton Boxes

- Foam-Filled Packaging

- Waterproof and Moisture-Proof Packaging

- Custom Packaging to Meet Client Specifications

- Logistics Options:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Courier Services

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Experience: Over a decade of experience in the non-ferrous metal industry, exporting to multiple global markets.

- Advanced Technology: Cutting-edge production equipment and processes, ensuring precision and quality.

- Custom Solutions: We offer OEM and ODM services to meet specific customer requirements.

- Global Reach: Exporting to countries including the U.S., Germany, South Korea, and Australia.

- Excellent Customer Service: A dedicated team providing technical support and after-sales service.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers flexible OEM/ODM services. We work closely with customers to develop custom solutions for their high-temperature applications. From material selection to final production, we ensure that every product meets exact specifications.

|

|

|

|

FAQ

-

What is the maximum operating temperature for TZM foil?

TZM foil can operate at temperatures up to 1,400°C, making it ideal for high-temperature applications. -

Can I order custom sizes?

Yes, we offer customized sizes for thickness, width, and length according to your specific requirements. -

Is TZM foil resistant to oxidation?

Yes, TZM foil offers excellent oxidation resistance, especially in inert or vacuum environments. -

What industries use TZM foil?

TZM foil is widely used in aerospace, nuclear power, energy, and industrial furnace applications. -

Do you provide sample testing?

Yes, we provide free samples for testing to qualified customers.

Contact Us

Contact us today for more information about our molybdenum high-temperature alloy TZM foil. Shaanxi Peakrise Metal Co., Ltd. is ready to meet your needs with top-quality products and reliable service. Email us at info@peakrisemetal.com to discuss your project requirements or to request a quote.