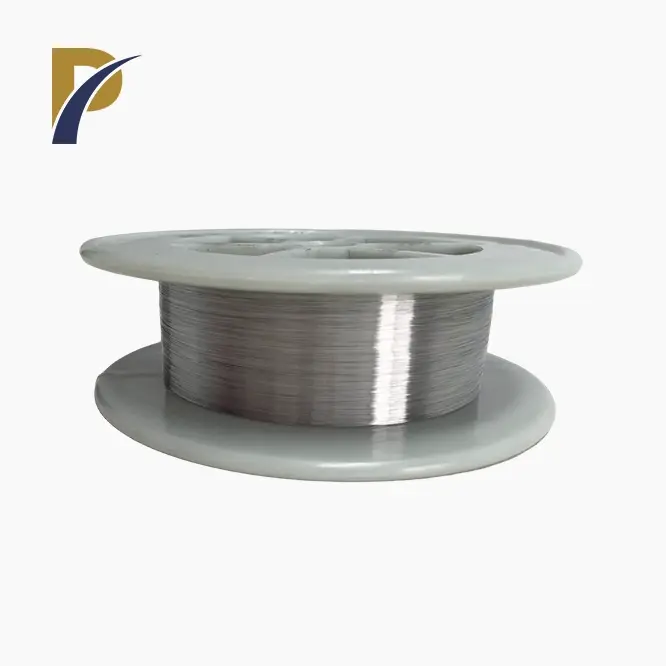

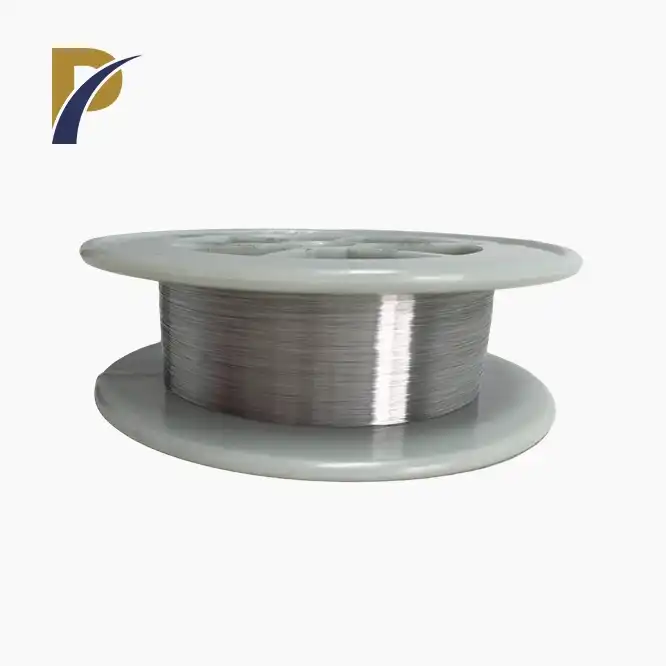

molybdenum welding wire

Purity: 99.95%

Density: 10.2g/cm3

Diameter: 0.01~3.18mm

Surface: Electropolished White,black

Standard: ASTM B387

Application: spray molybdenum wire, electric light source molybdenum wire, heating furnace molybdenum wire, electronic device molybdenum wire, and electric spark cutting molybdenum wire.

PRODUCT DESCRIPTION

Molybdenum Welding Wire - Shaanxi Peakrise Metal Co., Ltd.

Product Introduction

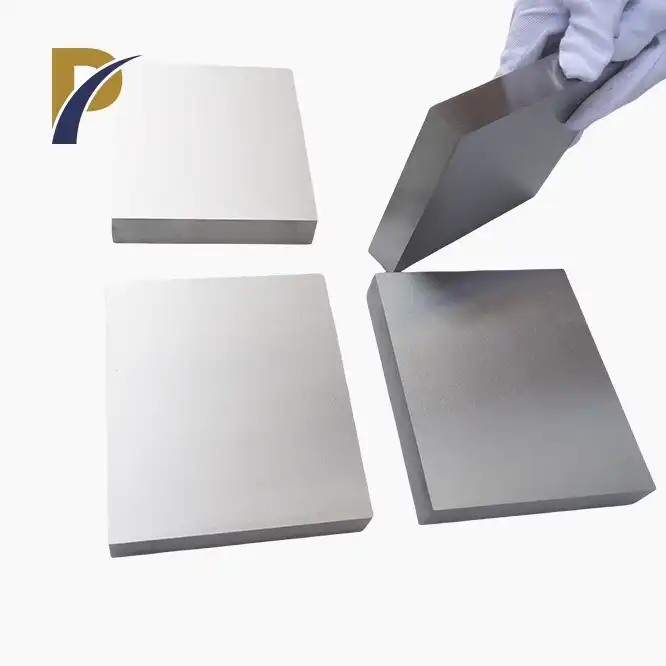

At Shaanxi Peakrise Metal Co., Ltd., we specialize in providing top-quality molybdenum welding wire designed to meet the rigorous demands of modern industrial applications. With our extensive experience in the production of non-ferrous metals, including tungsten, molybdenum, tantalum, and more, we have established ourselves as a leading supplier of advanced metal products. Our molybdenum welding wire is manufactured using state-of-the-art technology and adheres to the highest standards of quality and precision.

Molybdenum welding wire is renowned for its exceptional strength, high melting point, and excellent thermal conductivity. These properties make it an ideal choice for welding applications in industries such as aerospace, electronics, and high-temperature environments. Our commitment to quality ensures that our molybdenum welding wire delivers outstanding performance and reliability, making it a preferred choice for professionals seeking superior results.

Product Parameters

| Parameter | Value |

|---|---|

| Diameter | 0.5 - 6.0 mm |

| Length | 1000 - 3000 mm |

| Purity | 99.95% |

| Melting Point | 2620°C |

| Density | 10.28 g/cm³ |

| Electrical Resistivity | 5.0 x 10^-8 Ω·m |

|

|

|

Physical and Chemical Properties

- High Melting Point: Molybdenum welding wire boasts a melting point of 2620°C, which is significantly higher than many other metals, ensuring stability and durability in high-temperature applications.

- Excellent Thermal Conductivity: The wire exhibits superior thermal conductivity, making it effective for applications requiring efficient heat dissipation.

- Corrosion Resistance: It shows excellent resistance to oxidation and corrosion, enhancing its longevity and performance in demanding environments.

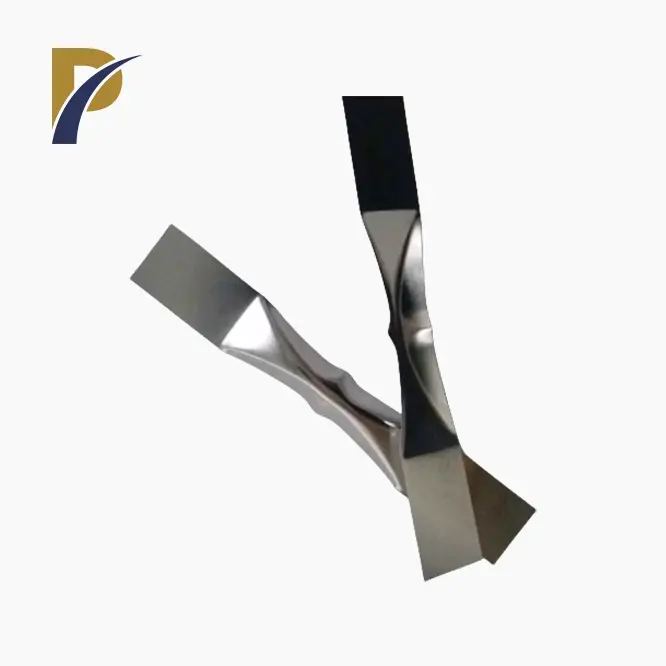

- High Strength: Molybdenum welding wire maintains high tensile strength, which is crucial for maintaining structural integrity during welding processes.

|

Molybdenum Content |

Other Elements Content Total |

Each Other Element Content |

| MO≥99.95% | ≤0.05% | ≤0.01% |

Product Functions

- High-Temperature Stability: With its high melting point, molybdenum welding wire maintains its integrity and performance even in extreme temperatures.

- Enhanced Durability: The wire’s resistance to corrosion and oxidation extends its service life, reducing the frequency of replacements and maintenance.

- Efficient Heat Transfer: Excellent thermal conductivity ensures effective heat management during welding, leading to better weld quality.

- Superior Mechanical Properties: High strength and stability under load make it suitable for demanding welding applications.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Aerospace Industry: Ideal for welding components that operate in high-temperature environments, such as jet engines and rocket nozzles.

- Electronics: Used in the production of electronic components that require precision and stability under high heat conditions.

- High-Temperature Furnaces: Suitable for welding furnace parts that must withstand intense heat and corrosive environments.

- Medical Devices: Applied in the manufacturing of medical equipment that requires high durability and precision.

|

|

Production Process and Workflow

Our molybdenum welding wire is produced through a meticulous process that includes:

- Raw Material Selection: We use high-purity molybdenum powder as the raw material to ensure superior quality.

- Wire Drawing: The molybdenum powder is compacted and drawn into wire form through precise mechanical processes.

- Heat Treatment: The wire undergoes heat treatment to achieve the desired physical and chemical properties.

- Quality Control: Rigorous testing is conducted to ensure that the wire meets our stringent quality standards before it is packaged and shipped.

|

|

Factory Introduction

Shaanxi Peakrise Metal Co., Ltd. is a premier manufacturer of non-ferrous metals, with extensive experience in producing tungsten, molybdenum, tantalum, and other specialty metals. Our state-of-the-art facility is equipped with advanced production technology and quality control systems to ensure the highest standards of product excellence. We are committed to innovation and continuous improvement to meet the evolving needs of our global customers.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

We offer comprehensive logistics solutions to ensure that our molybdenum welding wire reaches you in optimal condition. Our packaging is designed to protect the product during transit, and we work with trusted shipping partners to deliver your orders efficiently and on time.

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: Extensive experience in non-ferrous metal production.

- Quality: High standards of quality control and product excellence.

- Customization: Tailored solutions to meet specific customer requirements.

- Innovation: Commitment to continuous improvement and technological advancement.

- Global Reach: Reliable shipping and logistics solutions for worldwide delivery.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers OEM/ODM services to cater to your specific needs. Whether you require customized dimensions, packaging, or other specifications, our team is ready to provide tailored solutions to meet your exact requirements.

|

|

FAQs

Q: What is the typical diameter range for molybdenum welding wire? A: Our molybdenum welding wire is available in diameters ranging from 0.5 mm to 6.0 mm.

Q: What is the purity level of your molybdenum welding wire? A: Our molybdenum welding wire has a purity level of 99.95%.

Q: Can you provide customized sizes and packaging? A: Yes, we offer customized sizes and packaging options through our OEM services.

Q: How does your product perform in high-temperature environments? A: The wire has a high melting point of 2620°C, making it suitable for high-temperature applications.

Call to Action

Ready to experience the superior quality and performance of our molybdenum welding wire? Contact us today to discuss your needs and get a quote. Our expert team is here to assist you with tailored solutions and prompt service. Reach out to us at info@peakrisemetal.com or call +86-13186382597.