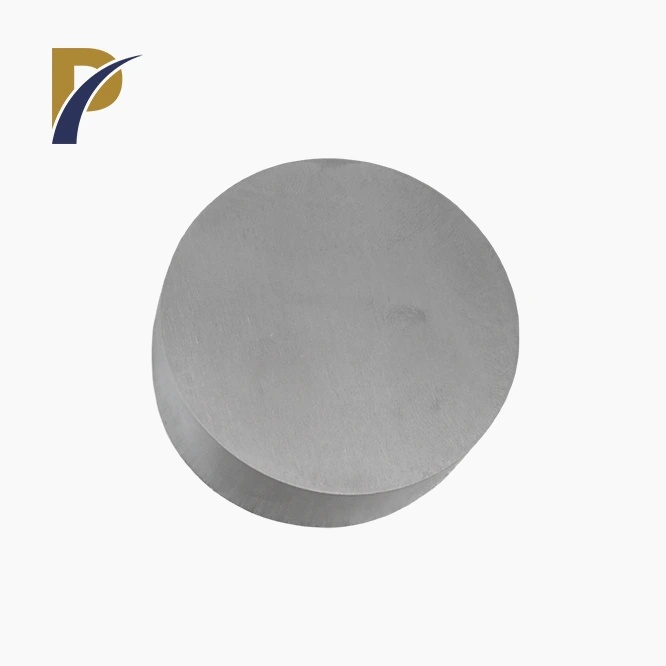

tungsten-molybdenum alloy rods

W Content: 50% (wt%)

Mo Content: 50% (wt%)

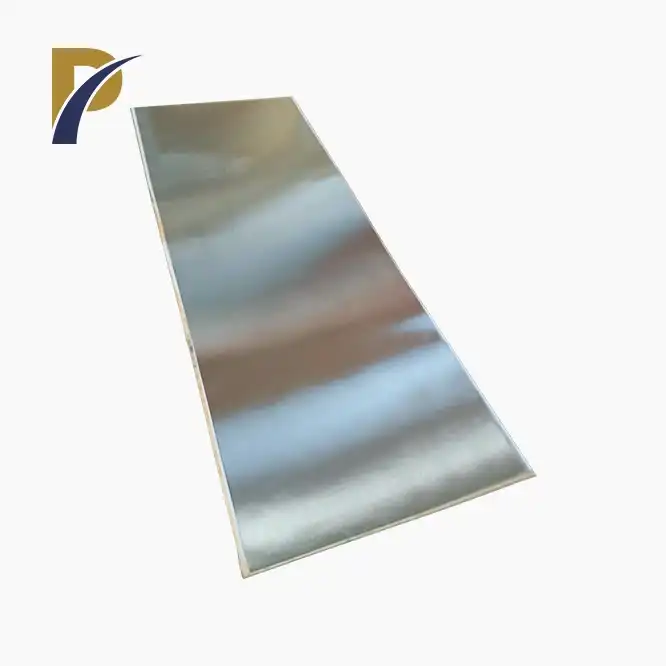

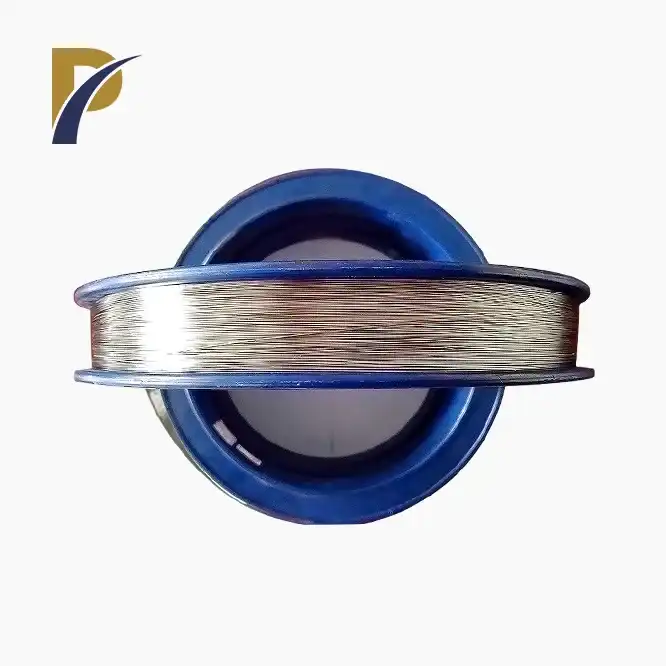

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is proud to offer high-quality tungsten-molybdenum alloy rods, known for their superior physical and chemical properties. Tungsten-molybdenum alloys have become a critical material in various industries due to their excellent heat resistance, high strength, and low coefficient of thermal expansion. These alloys are particularly advantageous in high-temperature environments and applications that require wear resistance, making them a popular choice for aerospace, electronics, and metallurgical industries. As a professional supplier, we ensure that each rod meets the strictest standards of quality and performance, providing solutions for both domestic and international markets.

With years of experience, Shaanxi Peakrise Metal Co., Ltd. has built a strong reputation as a leading supplier of tungsten-molybdenum alloy rods. Our production facilities, equipped with state-of-the-art technology, enable us to offer precision-engineered products tailored to meet specific customer requirements. Our commitment to high standards in manufacturing ensures that our rods maintain consistent quality, durability, and reliability, making us a trusted partner for global industrial applications.

Product Parameters

| Parameter | Specification |

|---|---|

| Material | W-Mo Alloy (Tungsten-Molybdenum Alloy) |

| Tungsten (W) Content | 10% ~ 50% (customizable) |

| Molybdenum (Mo) Content | Balance |

| Density | 10.2 ~ 16.5 g/cm³ (depending on W content) |

| Melting Point | 2620 ~ 3410 °C (varies with W content) |

| Thermal Conductivity | 100 ~ 150 W/m·K |

| Electrical Resistivity | 5.4 ~ 10.8 μΩ·cm |

| Coefficient of Thermal Expansion | 4.5 ~ 6.5 × 10⁻⁶/K |

| Hardness (HV) | 230 ~ 380 HV (varies with W content) |

| Tensile Strength | 617 ~ 900 MPa (depending on processing) |

| Surface Finish | Bright / Polished |

| Diameter Range | 5 ~ 150 mm |

| Length | ≤ 2000 mm (customizable) |

| Processing Method | Powder Metallurgy / Vacuum Melting |

| Application Industries | Aerospace, High-Temperature Furnaces, Electronics, Metallurgy, Medical Equipment |

| Customization | Available as per customer drawings |

| Packaging | Plywood Case, Secure Export Packaging |

| Minimum Order Quantity (MOQ) | 5 kgs |

| Supply Ability | 1000 kgs/month |

| Lead Time | 10~15 working days |

| Export Port | Any Port in China |

| Payment Terms | T/T, Negotiable |

|

|

|

Physical and Mechanical Properties

Tungsten-molybdenum alloys possess several key physical and mechanical properties that make them indispensable in industrial applications:

- High Melting Point: These alloys are capable of withstanding extreme temperatures, making them ideal for high-heat environments.

- Exceptional Strength: They provide excellent tensile strength, which ensures durability under mechanical stress.

- Low Thermal Expansion: Their low thermal expansion coefficient ensures minimal dimensional changes, which is essential for precision applications.

- High Thermal Conductivity: The material efficiently transfers heat, making it suitable for thermal management systems.

- Wear Resistance: Tungsten-molybdenum alloys resist wear and tear, ensuring long service life in heavy-duty industrial operations.

Product Functions

- Heat Resistance: Tungsten-molybdenum alloy rods can withstand temperatures up to 3410°C, making them ideal for use in high-temperature furnaces, aerospace components, and other demanding applications.

- Electrical Conductivity: These alloys are excellent conductors of electricity, making them suitable for electrical contacts and high-performance electronic devices.

- Corrosion Resistance: Tungsten-molybdenum alloys offer outstanding resistance to corrosion, particularly in harsh chemical environments.

- Dimensional Stability: Their low coefficient of thermal expansion ensures they retain their shape and size even under high-temperature fluctuations.

- Strength and Durability: The high tensile strength and creep resistance ensure long-lasting performance in mechanical applications.

Product Applications

- Aerospace Industry: Tungsten-molybdenum alloy rods are used in high-temperature components such as rocket nozzles and aircraft engines due to their heat resistance and strength.

- Electronics: These rods are essential in the manufacture of semiconductor components, electrodes, and electrical contacts, where their conductivity and stability are highly valued.

- Metallurgy: In the metallurgical industry, tungsten-molybdenum alloys are used in high-temperature furnaces, molds, and casting tools, offering excellent wear resistance.

- Medical Technology: The biocompatibility of these alloys makes them suitable for medical equipment and devices that require both strength and minimal reaction with human tissue.

- Defense Applications: The high-density and strength of tungsten-molybdenum alloys make them a key material for armor-piercing projectiles and defense-related components.

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we follow a meticulous production process to ensure that each tungsten-molybdenum alloy rod meets our quality standards:

- Raw Material Selection: Only the highest quality tungsten and molybdenum materials are used.

- Melting: The materials are melted in a vacuum arc furnace to ensure purity and consistency.

- Forming: The molten alloy is cast and shaped into rods through advanced rolling mills and wire drawing machines.

- Heat Treatment: The rods undergo vacuum annealing to improve their mechanical properties.

- Quality Inspection: Each batch is subjected to rigorous testing, including tensile strength, hardness, and dimensional accuracy checks.

Precision-Engineered Molybdenum-Tungsten Alloy Tailored to Your Needs!

At Peakrise Metal, your requirements take top priority. With over a decade of expertise, we transform complex ideas into practical solutions through our precision-engineered molybdenum tungsten alloy. From initial design to detailed specification adjustments, every step of our manufacturing process is customized to meet your exact demands.

Customization Options for Molybdenum Tungsten Alloy:

Size and Shape: Adjust the length, width, and overall design to match specific applications, ensuring seamless compatibility with various equipment and working conditions.

Purity: Choose from different molybdenum tungsten purity levels to achieve optimal performance in specialized applications.

Coating Treatment: Improve durability with tailored coatings, such as anti-oxidation or conductive layers, suited to specific environments.

Connection Design: Select customized connection methods, including welded joints or bolted structures, for secure and efficient installation.

Packaging: Opt for tailored packaging solutions that ensure safe transport and storage while maintaining product integrity.

Why choose molybdenum-tungsten alloy from Peakrise Metal?

At Peakrise Metal, we uphold industry-leading standards by integrating advanced techniques, innovative technology, and extensive expertise. Our dedication ensures that your specific needs are met with premium molybdenum tungsten alloy solutions.

Expertise and Experience: With over a decade in the industry, we combine cutting-edge technology with deep expertise to deliver top-tier molybdenum tungsten alloy tailored to your exact specifications.

Custom Solutions: We provide fully customized solutions, including unique sizes, shapes, and coatings, to meet precise performance requirements.

Unmatched Quality: Committed to superior manufacturing, we guarantee each molybdenum tungsten alloy product delivers exceptional performance, longevity, and reliability—ensuring excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Why Choose Us?

- Extensive Experience: Over a decade of expertise in producing high-quality non-ferrous metals.

- Global Reach: Our products are exported to over 20 countries, including the US, South Korea, and Germany.

- Cutting-Edge Equipment: We invest in the latest production technologies, including vacuum arc furnaces and CNC machines.

- Comprehensive Services: From product development to after-sales support, we ensure complete customer satisfaction.

- Strict Quality Control: Every product is subjected to rigorous testing to ensure it meets international standards.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers customized OEM/ODM services, providing tailored solutions to meet specific client requirements. Whether it's a unique specification or a large-scale production order, our experienced team can deliver products that perfectly match your needs.

FAQ

-

What is the delivery time for tungsten-molybdenum alloy rods? Typically, orders are delivered within 2-4 weeks, depending on the order size and customization.

-

Can you provide custom sizes for alloy rods? Yes, we offer custom sizes according to the specifications provided by our customers.

-

What payment methods do you accept? We accept wire transfers, letters of credit, and other secure payment methods.

-

Are your products compliant with international standards? Yes, all our products comply with ISO 9001 and other relevant international standards.

-

Do you offer samples for testing? Yes, we provide samples for testing upon request.

Contact Us

For more information about our tungsten-molybdenum alloy rods or to discuss your custom requirements, please contact us at info@peakrisemetal.com. We look forward to partnering with you for high-quality, reliable non-ferrous metal solutions.

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes for glass furnace

VIEW MOREmolybdenum electrodes for glass furnace -

VIEW MOREmolybdenum crucibles

VIEW MOREmolybdenum crucibles -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREmolybdenum sheet /plate for heat shield

VIEW MOREmolybdenum sheet /plate for heat shield -

VIEW MOREmolybdenum alloy strip foil

VIEW MOREmolybdenum alloy strip foil -

VIEW MOREmolybdenum heater wire

VIEW MOREmolybdenum heater wire -

VIEW MOREpolishing tantalum rod

VIEW MOREpolishing tantalum rod -

VIEW MOREhigh purity tantalum wire

VIEW MOREhigh purity tantalum wire

_1741251940277.webp)

_1741251940264.webp)

_1741251940298.webp)