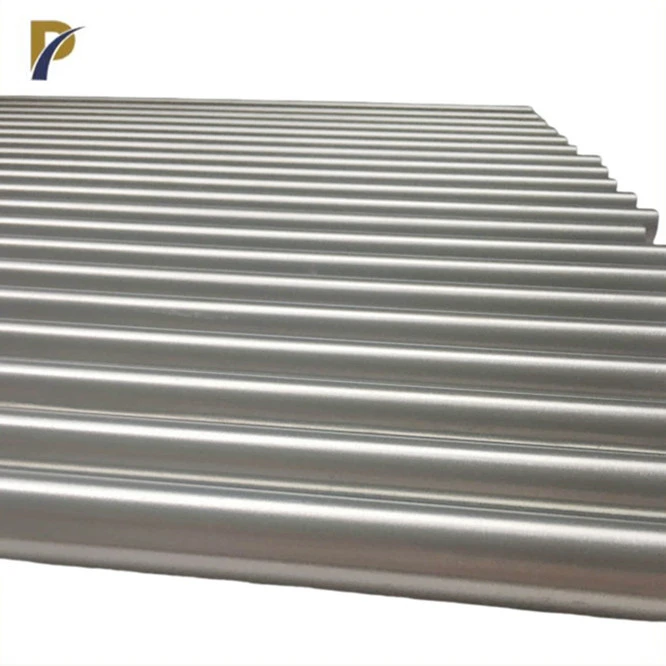

tungsten-molybdenum alloy rod

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Tungsten-Molybdenum Alloy Rod | High-Strength W-Mo Alloy for High-Temperature Applications

Product Name:

Tungsten-Molybdenum Alloy Rod – High Strength, Polished Surface

Grade:

W-Mo Alloy

Chemical Composition (%):

| Element | W | Mo | Fe | Si | Ni | C | O | N |

|---|---|---|---|---|---|---|---|---|

| Content | 48~53% | Balance | 0.01 | 0.01 | 0.005 | <0.03 | 0.0025 | 0.002 |

Specifications:

Diameter: 5–150mm

Length: ≤2000mm

Surface Finish: Bright, Polished

Customization: Can be machined into special shapes based on customer requirements.

Product Description:

Tungsten-molybdenum alloy rods are high-performance materials designed for extreme environments. This alloy combines the superior high-temperature resistance of tungsten with the enhanced ductility and machinability of molybdenum, making it ideal for aerospace, electronics, and industrial applications.

The W-Mo alloy rod exhibits excellent strength retention at high temperatures, low thermal expansion, and superior corrosion resistance. Its bright, polished surface ensures high purity and minimal oxidation, making it particularly suitable for vacuum furnace components, high-temperature structural parts, and advanced manufacturing industries.

Key Features:

High Melting Point: Can withstand temperatures above 2600°C, making it ideal for extreme heat applications.

Superior Mechanical Strength: Maintains structural integrity under high-temperature stress.

Excellent Creep Resistance: Ensures dimensional stability, critical for aerospace and industrial forming applications.

Low Thermal Expansion: Reduces material deformation under thermal cycling.

High Elastic Modulus: Enhances structural performance in demanding applications.

Corrosion and Oxidation Resistance: Suitable for harsh industrial environments.

|

|

|

Applications:

Aerospace & Defense: Used in rocket nozzles, high-temperature components, and structural parts.

Electronics & Semiconductors: Ideal for electrical contacts, heating elements, and semiconductor processing.

Vacuum Furnace Components: Suitable for crucibles, heat shields, and support structures.

Glass and Metal Processing: Used in high-temperature molds and electrode components.

Medical & Research Fields: Applied in radiation shielding and high-energy physics research.

|

|

Manufacturing Process:

Raw Material Selection: High-purity tungsten and molybdenum powders.

Mixing & Blending: Precise alloy composition control.

Pressing & Forming: Shaped under high pressure for uniform density.

Sintering: High-temperature sintering for enhanced mechanical properties.

Forging & Rolling: Optimized for strength and ductility.

Heat Treatment: Improves performance characteristics.

Precision Machining: Custom processing based on specifications.

Quality Control & Inspection: Strict adherence to ASTM and industry standards.

Precision-Engineered Molybdenum-Tungsten Alloy Rod Tailored to Your Needs!

At Peakrise Metal, your requirements take top priority. With over a decade of expertise, we transform complex ideas into practical solutions through our precision-engineered molybdenum tungsten alloy. From initial design to detailed specification adjustments, every step of our manufacturing process is customized to meet your exact demands.

Customization Options for Molybdenum Tungsten Alloy:

Size and Shape: Adjust the length, width, and overall design to match specific applications, ensuring seamless compatibility with various equipment and working conditions.

Purity: Choose from different molybdenum tungsten purity levels to achieve optimal performance in specialized applications.

Coating Treatment: Improve durability with tailored coatings, such as anti-oxidation or conductive layers, suited to specific environments.

Connection Design: Select customized connection methods, including welded joints or bolted structures, for secure and efficient installation.

Packaging: Opt for tailored packaging solutions that ensure safe transport and storage while maintaining product integrity.

Why choose molybdenum-tungsten alloy from Peakrise Metal?

At Peakrise Metal, we uphold industry-leading standards by integrating advanced techniques, innovative technology, and extensive expertise. Our dedication ensures that your specific needs are met with premium molybdenum tungsten alloy solutions.

Expertise and Experience: With over a decade in the industry, we combine cutting-edge technology with deep expertise to deliver top-tier molybdenum tungsten alloy tailored to your exact specifications.

Custom Solutions: We provide fully customized solutions, including unique sizes, shapes, and coatings, to meet precise performance requirements.

Unmatched Quality: Committed to superior manufacturing, we guarantee each molybdenum tungsten alloy product delivers exceptional performance, longevity, and reliability—ensuring excellent value for your investment.

Our workshop

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Package

|

|

|

|

|

|

|

|

|

|

Certificate

|

Quality Assurance:

Certified Materials: Meets ASTM B386 and other international quality standards.

Strict Quality Control: Each rod undergoes thorough inspection for chemical composition, mechanical properties, and surface finish.

Custom Manufacturing: Tailored solutions to meet unique industry requirements.

Packaging & Logistics:

Secure, moisture-proof packaging to prevent oxidation during transit.

Custom labeling and international shipping available.

Delivery to any port in China or global export as per customer requirements.

Why Choose Us?

Industry Expertise: Years of experience in tungsten-molybdenum alloy production.

Customization: Tailored solutions for diverse industrial applications.

Competitive Pricing: High-quality products at cost-effective rates.

Reliable Supply Chain: Efficient logistics ensuring on-time delivery.

Dedicated Customer Support: Expert guidance for material selection and application.

Get a Quote Today!

Looking for high-quality tungsten-molybdenum alloy rods? Contact us now for a competitive quote and expert assistance.

📩 Email: info@peakrisemetal.com

📱 WhatsApp: +8613186382597

YOU MAY LIKE

-

VIEW MOREmolybdenum glass melting electrodes

VIEW MOREmolybdenum glass melting electrodes -

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MORE8mm tungsten rod

VIEW MORE8mm tungsten rod -

VIEW MOREpure tungsten wire

VIEW MOREpure tungsten wire -

VIEW MOREsic rod heater element

VIEW MOREsic rod heater element -

VIEW MOREu shape sic heating element Silicon Carbon rod

VIEW MOREu shape sic heating element Silicon Carbon rod

_1741251271648.webp)

_1741251271650.webp)

_1741251271659.webp)

_1741251271646.webp)