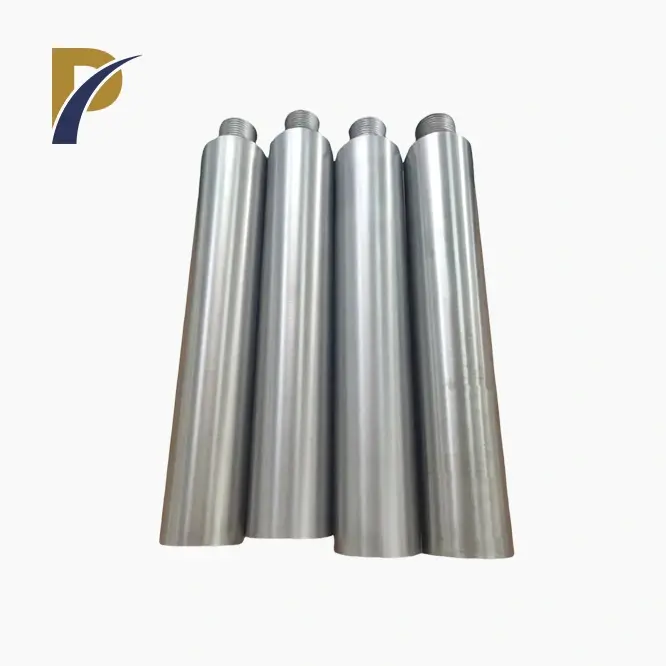

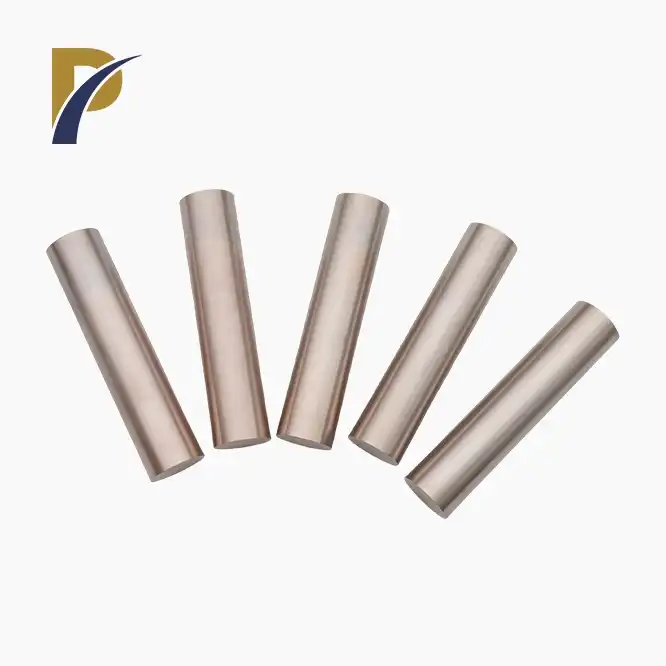

slivery color molybdenum sheet /plate

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is proud to offer top-quality slivery color molybdenum sheets and plates to the global market. Molybdenum is known for its excellent strength at high temperatures, low coefficient of thermal expansion, and superior conductivity. As one of the premier materials in industries that demand durability and resistance to extreme environments, molybdenum sheets and plates are widely used in aerospace, electronics, and high-temperature furnaces. Our slivery color molybdenum sheet/plate products are manufactured to meet the highest standards, ensuring that they deliver exceptional performance and reliability in your applications.

With over a decade of experience in producing non-ferrous and refractory metals, Shaanxi Peakrise Metal Co., Ltd. has become a trusted supplier of molybdenum products worldwide. We employ cutting-edge manufacturing processes and adhere to strict quality control to ensure that each molybdenum sheet and plate meets your exact specifications. Our expertise in molybdenum sheet/plate production allows us to offer customized solutions for specific industrial needs, providing you with tailored products that fit seamlessly into your production processes.

Product Parameters Table

Below are the specifications for our slivery color molybdenum sheet/plate products. Each product is made to precise measurements and high-quality standards:

| Parameter | Value |

|---|---|

| Material | Molybdenum (Mo) |

| Purity | ≥ 99.95% |

| Thickness | 0.1mm - 50mm |

| Width | 50mm - 600mm |

| Length | 100mm - 2000mm |

| Surface Finish | Polished, Chemical Cleaned |

| Density | 10.2 g/cm³ |

| Melting Point | 2620°C |

Additional Specification Tables:

| Mechanical Property | Value |

|---|---|

| Tensile Strength | 600 - 650 MPa |

| Yield Strength | 480 - 520 MPa |

| Elongation | 15 - 25% |

| Hardness (HV) | 200 - 230 |

|

|

|

Physical and Mechanical Properties

The molybdenum sheet/plate has exceptional properties that make it ideal for a wide range of demanding industrial applications:

- High Melting Point: With a melting point of 2620°C, molybdenum offers excellent heat resistance, making it suitable for use in extreme temperature environments.

- Low Coefficient of Thermal Expansion: Molybdenum has a lower expansion rate than most metals, meaning it maintains stability when exposed to temperature variations, which is crucial for high-precision applications.

- Corrosion Resistance: Molybdenum resists oxidation and corrosion, extending the lifespan of parts in harsh operating conditions.

- High Electrical Conductivity: Its superior conductivity makes molybdenum sheets/plates an excellent material for electronic components and circuits.

- Strength at High Temperatures: Molybdenum maintains its mechanical strength even at high temperatures, ensuring reliability in critical applications.

| Product Name | Molybdenum sheet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tensile strength | 610 Mpa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Elongation | ≥10% | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity | ≥99.95%,≥99.97%, | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Size | TK 0.1~80mm*W 10~700mm*L 30~3000mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Use temperature | 1800°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Highest temperature | 2200°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Cd | Ca | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | N | Sb | Sn | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Functions

Our slivery color molybdenum sheet/plate performs several critical functions across different industries:

- Thermal Shielding: Due to its heat resistance, molybdenum is often used in thermal barriers in furnaces and high-temperature environments.

- Conductivity Component: Its high conductivity makes it suitable for use in electrical contacts and semiconductor components.

- Structural Integrity: Molybdenum provides superior strength and rigidity, even at elevated temperatures, making it valuable in aerospace applications.

- Corrosion Resistance Layer: It acts as a protective layer in corrosive environments, ensuring that machinery and components remain in optimal working condition.

- Catalytic Agent: In chemical processing, molybdenum is used as a catalyst, enabling various reactions without degrading.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

Our slivery color molybdenum sheet/plate is versatile and valuable in multiple industries due to its unique properties:

- Aerospace Industry: Molybdenum is widely used in high-temperature structural parts, rocket nozzles, and heat shields.

- Semiconductor Industry: It is essential in semiconductor components due to its high conductivity and resistance to extreme heat.

- Medical Equipment: Molybdenum’s biocompatibility makes it suitable for use in medical devices and implants.

- Glass Manufacturing: It is used in the production of glass fiber and glass products because of its durability at high temperatures.

- Nuclear Energy: Molybdenum is used in the containment of radioactive materials, thanks to its strength and thermal stability.

|

|

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we follow a stringent production process to ensure the highest quality of molybdenum sheets and plates:

- Raw Material Sourcing: Only high-purity molybdenum is sourced from certified suppliers.

- Vacuum Melting: The material is melted in a vacuum to ensure uniformity and remove impurities.

- Rolling: Sheets and plates are rolled to precise thicknesses, meeting exact specifications.

- Annealing: The material is heat-treated to enhance mechanical properties and ensure strength and durability.

- Surface Treatment: Various surface finishes are applied, including polishing and chemical cleaning, to improve the product's appearance and performance.

- Quality Inspection: Each sheet and plate undergoes rigorous testing to ensure they meet mechanical and chemical standards.

|

|

|

|

Our Factory

Our factory is equipped with state-of-the-art production facilities, including:

- Intermediate frequency sintering furnace

- Vacuum arc melting furnace

- CNC machining equipment

- Plasma welding rooms

- Advanced testing and quality control systems

We maintain a robust inventory and offer quick turnaround times, ensuring that we meet the demands of our customers worldwide.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Packaging and Logistics

We provide multiple packaging options to ensure your products are delivered safely:

- Wooden crates: For heavy-duty protection.

- Carton packaging: Lightweight and cost-effective.

- Foam-filled boxes: For added cushioning during transit.

- Waterproof and moisture-proof packaging: Ideal for international shipping.

Logistics options include:

- Sea freight: Economical for bulk orders.

- Air freight: Faster delivery for urgent needs.

- Land transport: Efficient for domestic shipping.

- Courier services: Ideal for small shipments.

|

|

|

|

|

|

|

|

Why Choose Us?

Here’s why Shaanxi Peakrise Metal Co., Ltd. is your ideal partner:

- Decades of Experience: Over 10 years in the non-ferrous metal industry.

- Comprehensive Product Range: We offer over 100 types of non-ferrous metal products.

- Global Reach: Our products are exported to numerous countries, including the U.S., Germany, and Australia.

- Advanced Facilities: Equipped with cutting-edge machinery to produce high-quality products.

- Customer-Centric Approach: Focused on providing high-quality service and customized solutions.

OEM/ODM Services

We offer comprehensive OEM and ODM services to meet your specific requirements. Whether you need a custom size, thickness, or surface finish, our team is here to support your unique needs.

|

|

FAQ

Q1: What is the minimum order quantity (MOQ)?

A1: Our MOQ is typically 100 kg, but we can accommodate smaller orders based on customer requirements.

Q2: Can you provide free samples?

A2: Yes, we offer free samples for testing.

Q3: How long is your lead time?

A3: For standard products, our lead time is 7-14 days. Custom orders may take longer.

Q4: Do you offer international shipping?

A4: Yes, we ship worldwide and offer various shipping methods to suit your needs.

Q5: What payment methods do you accept?

A5: We accept T/T, L/C, and other common payment methods.

Contact Us

For more information or to place an order, please contact us at info@peakrisemetal.com. We look forward to working with you!