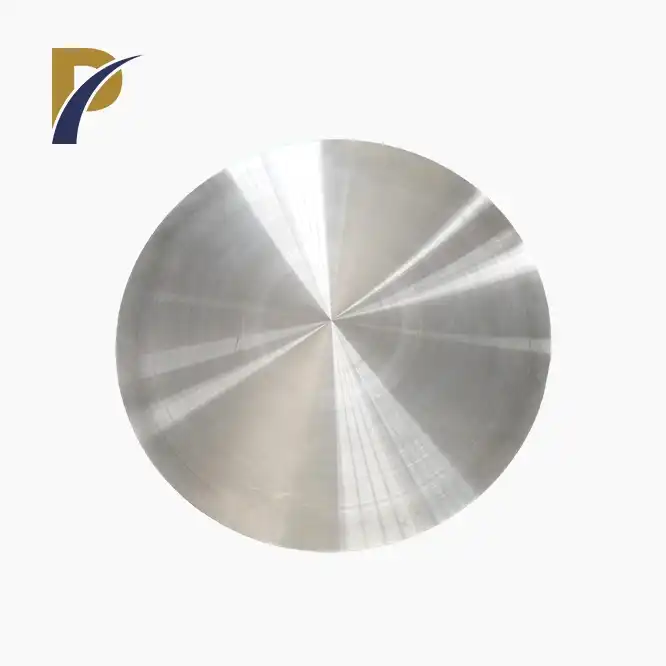

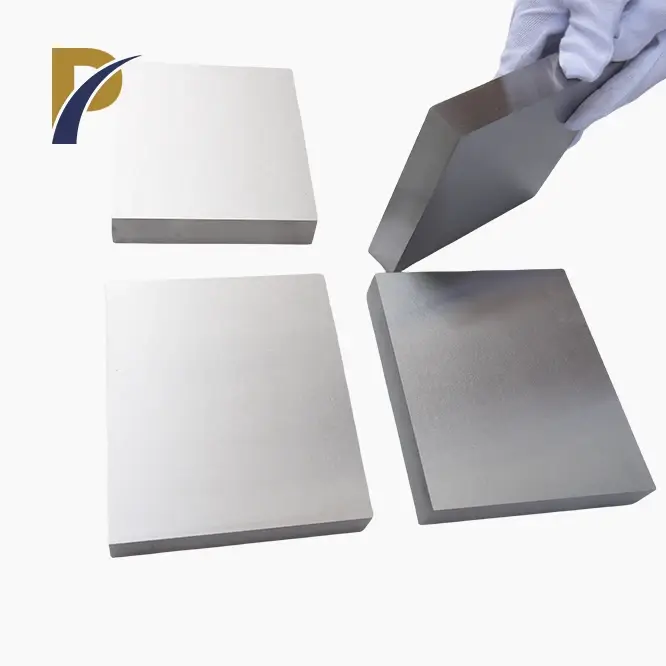

high quality molybdenum plate

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

High Quality Molybdenum Plate – Product Introduction

Molybdenum plate is an important product, which is made of molybdenum material. Molybdenum products with a thickness of 0.2~20mm are called molybdenum plates. Molybdenum plate is widely used in the production of high temperature furnace parts and electronic component materials.

At Shaanxi Peakrise Metal Co., Ltd., we pride ourselves on our comprehensive production capabilities. We have established ourselves as a leading player in the global molybdenum plate market. With over a decade of experience, our products are trusted by clients in countries such as the United States, Germany, South Korea, Australia, and many others. This trust is built on our commitment to delivering only the finest molybdenum plates, tailored to meet the specific needs of each client. Whether you need small quantities for a niche project or large orders for mass production, our manufacturing process ensures consistent quality across all batches.

Product Parameter

Molybdenum plate

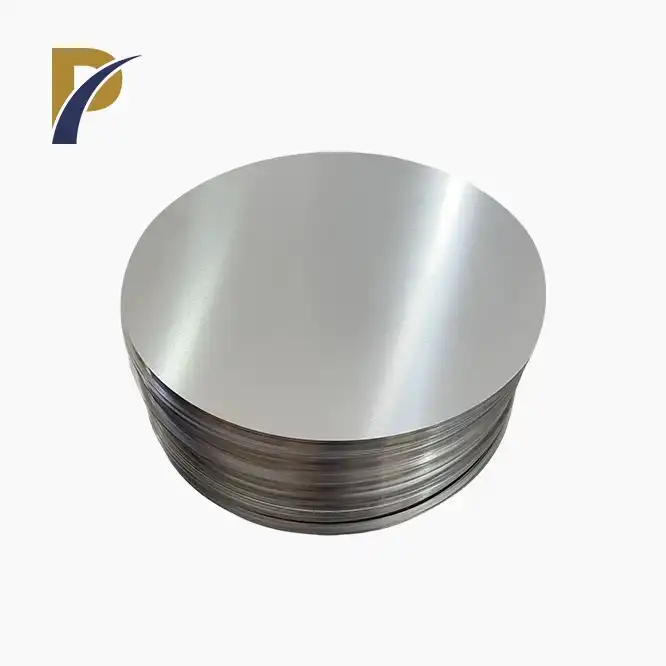

thickness:0.2mm-20mm wideth:10-700mm length:<2500mm

Purity:99.95%,99.97%

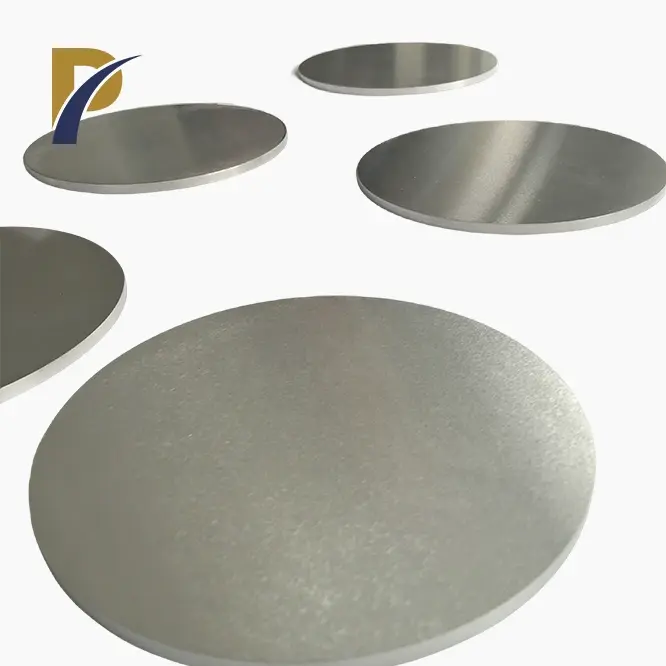

Grade:Mo-1,TZM,Mo-La,361,364

Standard:ASTM B386

Surface:black,polished,Alkaline washing,sandblasting

|

|

|

Physical and Mechanical Properties

Molybdenum’s physical and mechanical properties make it suitable for a range of demanding applications. Our molybdenum plates are highly resistant to heat and corrosion, making them ideal for use in environments that require stability under extreme conditions.

- High Melting Point: Molybdenum has a melting point of 2620°C, which makes it suitable for high-temperature applications.

- Excellent Thermal Conductivity: The material’s high thermal conductivity ensures effective heat dissipation.

- Corrosion Resistance: Molybdenum’s excellent resistance to corrosion, especially at high temperatures, makes it a preferred choice for use in harsh environments.

- Durability and Strength: The material is known for its excellent strength and durability, maintaining its structural integrity even under extreme pressure.

| Material type |

Condition

|

Thickness inches(mm) | Tensile Strength B Min, klb/in2 (MPa) | Yield Strength 0.2% Residual Deformation, Min, klb/in2 (mm) | Elongation, min, % (2 inches or 50 mm) | Minimum bending radius |

| 361 | SR | ≤0.001(0.025) | 115(795) | 95(655) | 1 | |

| 364 | SR | 0.01~0.025(0.25~0.635) | 120(830) | 100(690) | 6 | 2t |

| ≥0.025~0.06(0.635~1.5) | 120(830) | 100(690) | 7 | 2t | ||

| ≥0.06~0.09(1.5~2.3) | 100(690) | 100(690) | 9 | |||

| ≥0.09~0.189(2.3~4.75) | 120(830) | 100(690) | 10 | |||

| 3/16~1/2(4.75~12.7) | 120(830) | 100(690) | 10 | |||

| ≥1/2~1(12.7~25.4) | 110(760) | 95(655) | 10 | |||

| ≥1~1-1/2(25.4~38) | 100(690) | 85(585) | 8 | |||

| 364 | RX | ≥3/16~1-1/2(4.75~38) | 75(515) | 45(310) | 10 | |

|

A SR=stress relief; RX=almost completely recrystallized , B Longitudinal and transverse testing between 65°F and 85°F (18°C and 29°C) C t=Material thickness D is limited by transverse rolling, transverse elongation is easy to edge. |

||||||

Product Functions

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

Molybdenum plates are versatile and are used across a wide range of industries. Their properties make them indispensable in applications that demand durability, heat resistance, and corrosion resistance.

- Aerospace Industry: Used in manufacturing components that must withstand extreme temperatures and pressures.

- Electronics: Molybdenum plates are employed in semiconductor devices, where they act as efficient conductors of heat and electricity.

- Nuclear Industry: Due to its high resistance to heat and radiation, molybdenum plates are used in nuclear reactors and radiation shielding.

- Chemical Processing: Molybdenum’s corrosion-resistant properties make it an ideal material for handling corrosive chemicals in the manufacturing process.

- Medical Devices: Its biocompatibility and strength make it suitable for use in medical equipment and implants.

|

|

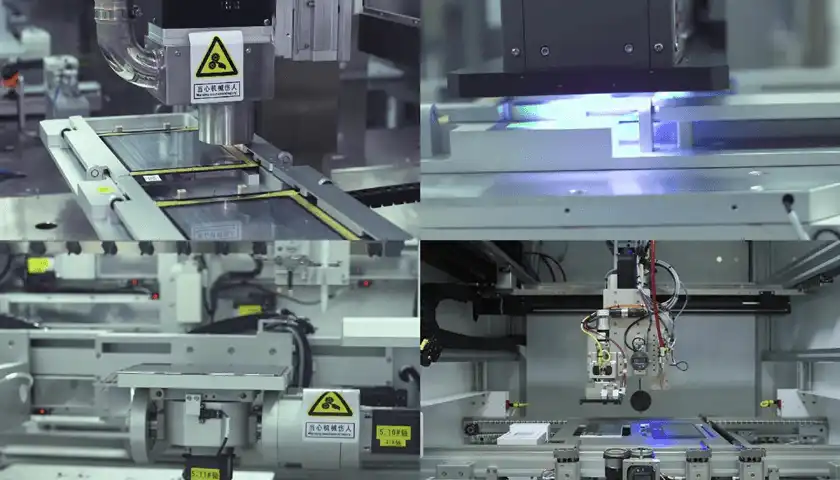

Product Process and Production Flow

At Shaanxi Peakrise Metal Co., Ltd., we utilize cutting-edge technology and state-of-the-art equipment to ensure the highest quality in every molybdenum plate we produce. Our production process involves several key stages:

- Raw Material Selection: We source high-purity molybdenum ore to ensure the superior quality of our final product.

- Melting: Using vacuum arc melting and plasma electron beam melting furnaces, we achieve a high degree of purity and uniformity.

- Rolling: Our plates are rolled using advanced rolling mills, ensuring they meet the precise thickness and dimensional tolerances.

- Annealing: To enhance the mechanical properties, our molybdenum plates undergo vacuum annealing.

- Testing and Quality Control: Every batch is rigorously tested for mechanical strength, chemical composition, and dimensional accuracy.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. is equipped with a variety of advanced production equipment, including vacuum arc melting furnaces, laser cutters, and rolling mills. Our factory spans a large area, enabling us to handle large orders efficiently. With our highly skilled workforce and state-of-the-art machinery, we ensure that each product meets stringent quality standards.

Logistics and Packaging

- Packaging Options:

- Wooden crates for enhanced protection.

- Carton boxes with foam inserts for smaller orders.

- Custom packaging solutions to meet specific requirements.

- Waterproof and moisture-resistant packaging to ensure product integrity during transit.

- Logistics:

- We offer flexible shipping options, including sea freight, air freight, and land transportation.

- Multimodal transportation is available for optimized delivery times.

- Expedited courier services are also offered for urgent orders.

|

|

|

|

|

|

|

|

Why Choose Us?

- Rich Industry Experience: With over ten years of experience in the non-ferrous metals industry, we understand the specific needs of various sectors.

- Comprehensive Product Line: Our product range includes over 100 types of non-ferrous metal products, catering to a wide variety of applications.

- Global Reach: We serve customers worldwide, with exports to over 20 countries, including the United States, South Korea, Germany, and Australia.

- Advanced Manufacturing Capabilities: Our state-of-the-art machinery ensures that we can meet the most stringent quality standards.

- Commitment to Quality: Our ISO 9001-certified quality management system ensures that every product leaving our factory meets the highest international standards.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers customized OEM and ODM services. Whether you need specific dimensions, surface treatments, or special packaging, we are equipped to meet your unique requirements. Our team works closely with clients to deliver tailor-made solutions.

|

|

FAQ

-

What is the minimum thickness of your molybdenum plates?

- We offer plates as thin as 0.1 mm, which is ideal for specialized applications.

-

Can you provide custom dimensions for molybdenum plates?

- Yes, we offer fully customized sizes based on your specifications.

-

What is your production capacity?

- We can produce up to 500 tons of molybdenum plates per year.

-

How do you ensure the quality of your products?

- All our products undergo rigorous quality testing, including mechanical strength, chemical composition, and dimensional accuracy.

-

Do you offer international shipping?

- Yes, we ship our products worldwide using sea, air, and land transportation methods.

Contact Us

For more information or to place an order, please contact us at info@peakrisemetal.com. We look forward to partnering with you to provide high-quality molybdenum plates for your industrial needs. Our team is ready to assist with any custom requirements you may have.