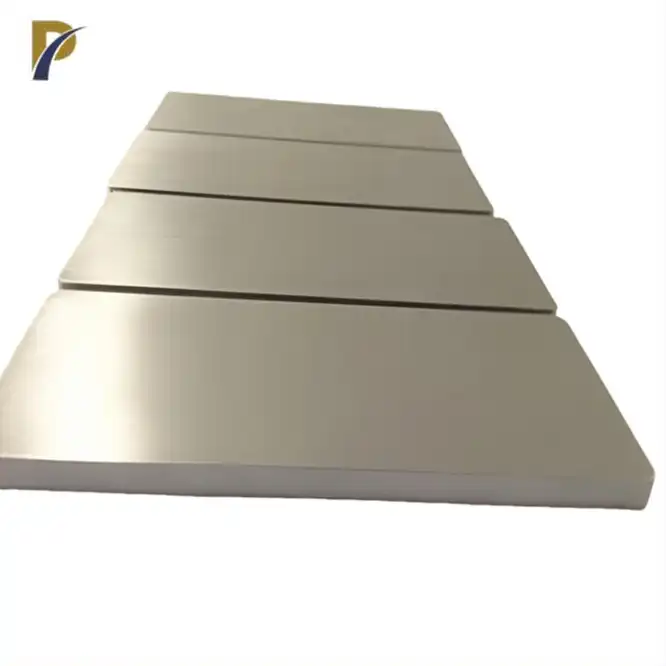

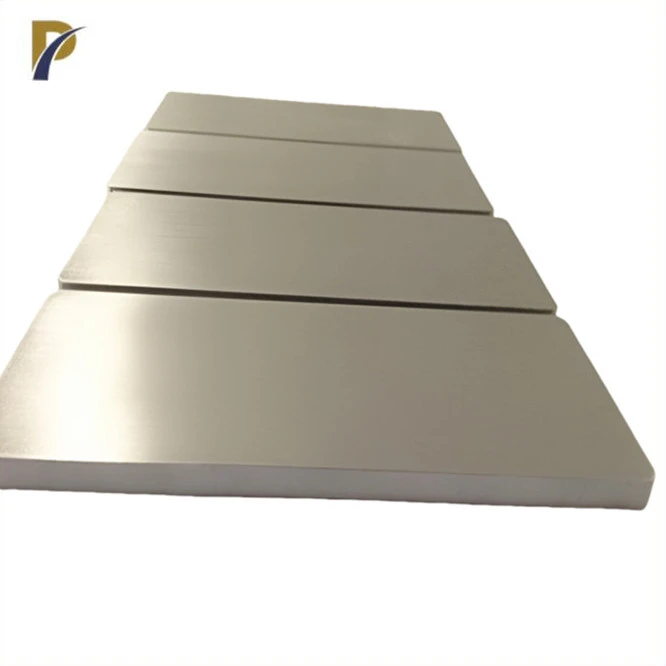

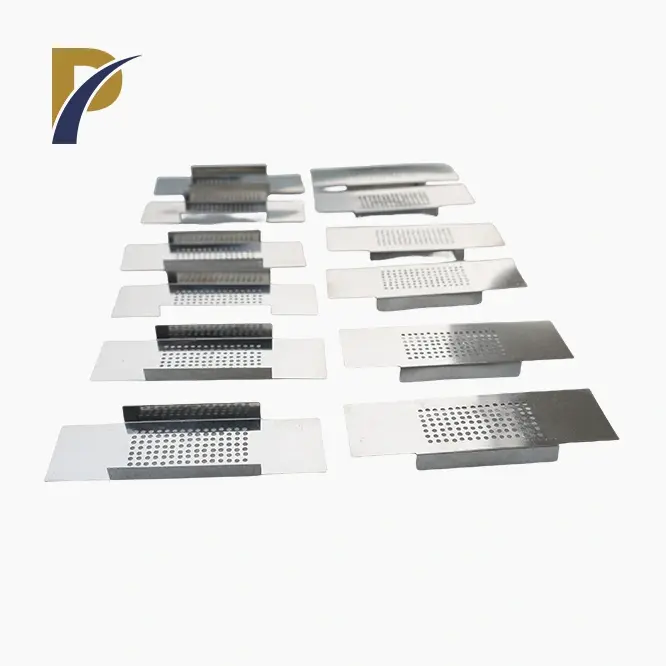

ground molybdenum plate

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

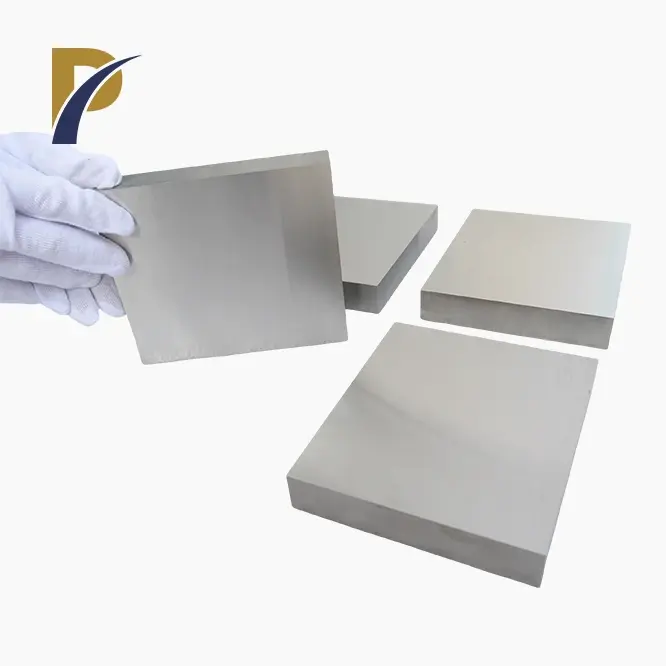

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

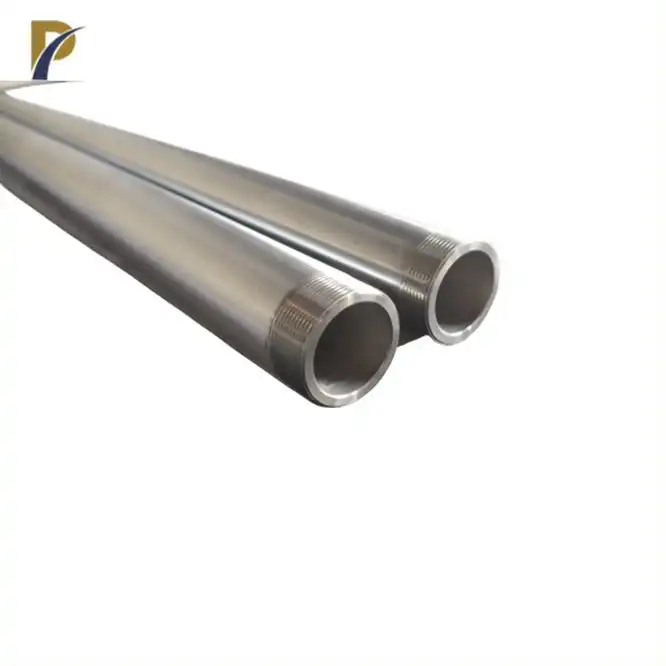

Product Introduction: Ground Molybdenum Plate

Shaanxi Peakrise Metal Co., Ltd. is proud to be a leading supplier of ground molybdenum plates, offering high-quality solutions for a variety of industrial applications. Molybdenum is known for its exceptional strength, high melting point, and excellent thermal conductivity, making it ideal for environments that demand resilience under extreme conditions. Our ground molybdenum plates are produced through precise grinding processes to ensure surface smoothness and dimensional accuracy, providing reliable performance in high-temperature and corrosion-resistant environments.

As a trusted ground molybdenum plate supplier, Shaanxi Peakrise Metal Co., Ltd. specializes in the manufacturing and customization of molybdenum products to meet the diverse needs of industries worldwide. Whether you require plates for semiconductor, aerospace, defense, or energy sectors, our products are crafted to exceed industry standards.

With over a decade of experience in non-ferrous metal production, we have honed our expertise in molybdenum materials. Our commitment to quality, consistency, and customer satisfaction sets us apart in the global market.

|

|

|

Product Parameters

| Parameter | Value |

|---|---|

| Purity | ≥ 99.95% |

| Thickness | 0.5 mm to 50 mm |

| Width | Up to 600 mm |

| Length | Up to 1000 mm |

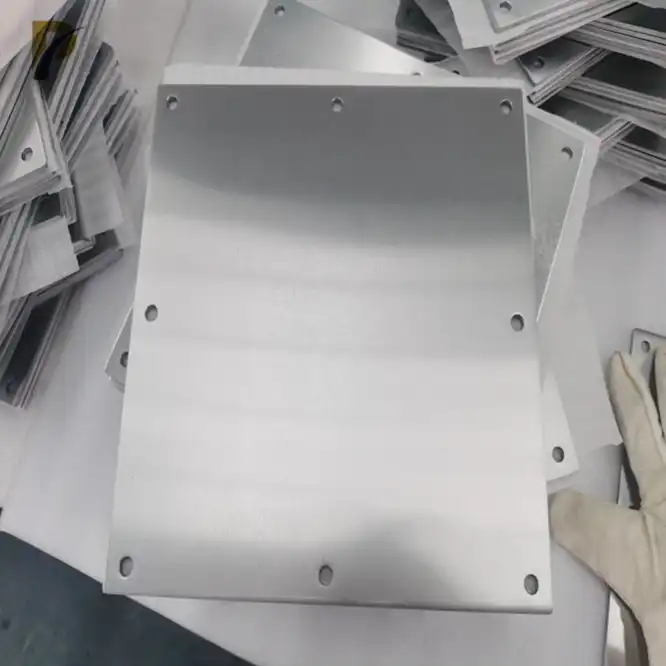

| Surface Finish | Ground, polished |

| Density | 10.2 g/cm³ |

| Melting Point | 2623°C |

| Electrical Resistivity | 5.3 x 10⁻⁸ Ω·m |

| Property | Value |

|---|---|

| Thermal Conductivity | 138 W/m·K |

| Tensile Strength | 690 MPa |

| Hardness (HV) | 250 HV |

| Modulus of Elasticity | 320 GPa |

| Thermal Expansion Coefficient | 4.8 x 10⁻⁶ /K |

| Processing Capability | Range |

|---|---|

| Maximum Custom Size | As per customer requirements |

| Cutting Precision | ± 0.01 mm |

| Tolerances | As low as ± 0.005 mm |

| Delivery Condition | Annealed or Cold Rolled |

Physical and Mechanical Properties

Ground molybdenum plates possess unique physical and mechanical properties that make them suitable for demanding applications. The high melting point of molybdenum ensures performance stability in high-temperature environments, while its excellent thermal conductivity makes it a perfect fit for thermal management in critical applications. Molybdenum’s low coefficient of thermal expansion minimizes deformation under thermal stress, maintaining its structural integrity even under extreme conditions.

Product Functions

- Thermal Management: Due to its superior thermal conductivity, molybdenum plates are widely used for heat dissipation in electronic components.

- Corrosion Resistance: Molybdenum exhibits excellent resistance to corrosion in acidic and high-temperature environments, making it ideal for chemical processing applications.

- High Strength: Ground molybdenum plates offer excellent mechanical strength, which makes them suitable for structural applications requiring durability and resistance to mechanical wear.

- Dimensional Stability: The low thermal expansion coefficient ensures that molybdenum plates retain their dimensions, even in high-temperature environments, essential for precision engineering applications.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Semiconductor Industry: Ground molybdenum plates are used as substrates and heat spreaders in semiconductor manufacturing due to their excellent thermal properties.

- Aerospace and Defense: Molybdenum’s high strength and stability at elevated temperatures make it a reliable choice for components in aircraft and military equipment.

- Energy Sector: In high-temperature furnaces and reactors, molybdenum plates are used for structural support and thermal insulation.

- Medical Equipment: Molybdenum plates are used in medical imaging devices and radiation shielding due to their ability to block radiation.

- Nuclear Industry: The high melting point and corrosion resistance of molybdenum make it suitable for use in nuclear power plants.

|

|

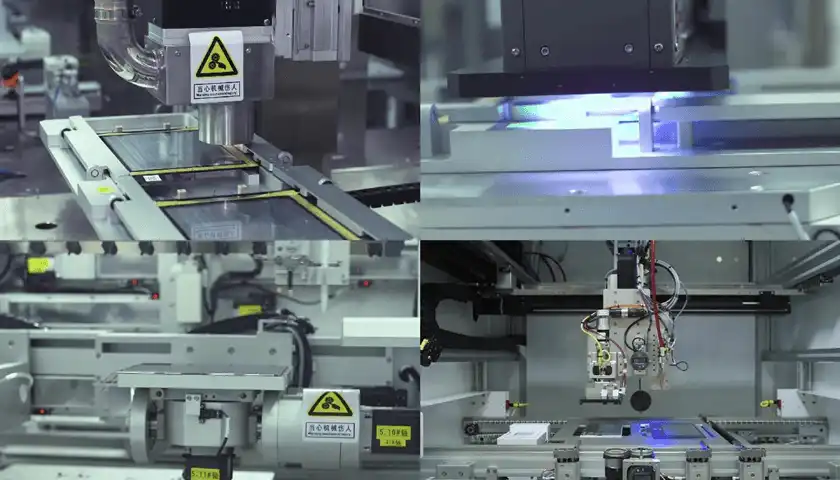

Product Process and Production Flow

Our ground molybdenum plates are manufactured using high-quality raw molybdenum materials. The production process includes:

- Raw Material Selection: High-purity molybdenum powder is sourced from trusted suppliers.

- Sintering: The powder is compacted and sintered in a high-temperature furnace to form solid molybdenum billets.

- Rolling: The billets are hot-rolled to the required thickness, followed by cold rolling for precise dimensional control.

- Grinding: A precision grinding process is applied to achieve the desired surface finish and flatness.

- Annealing: To enhance the mechanical properties, molybdenum plates are annealed in a controlled atmosphere.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art facility equipped with advanced production equipment, including vacuum sintering furnaces, electron beam melting furnaces, and precision rolling mills. Our quality control team ensures that every product meets the highest industry standards through rigorous testing and inspection procedures.

|

|

|

|

Logistics and Packaging

- Wooden Packaging: Secure and durable wooden crates are used for safe transportation.

- Carton Packaging: For smaller items, we use reinforced carton boxes.

- Foam-Filled Packaging: Items are cushioned with foam to prevent damage during transit.

- Waterproof and Moisture-Proof Packaging: Ensures the products remain free from environmental damage.

- Custom Packaging: Tailored packaging solutions to meet specific customer requirements.

Logistics Options:

- Sea Freight: Suitable for large and bulk orders.

- Air Freight: Fast and efficient for time-sensitive deliveries.

- Land Transport: For shipments within the region or connected via land routes.

- Multimodal Transport: A combination of sea, air, and land transport to optimize cost and time.

- Courier Services: Ideal for small orders and samples, ensuring rapid delivery.

|

|

|

|

|

|

|

|

Why Choose Us?

- Comprehensive Expertise: With over a decade of experience, we have a deep understanding of molybdenum and other non-ferrous metals.

- State-of-the-Art Facility: Our advanced production equipment ensures precision and consistency in every product.

- Global Reach: We export to numerous countries and have established long-term partnerships with international clients.

- Customization Options: We offer full OEM/ODM services to meet the specific needs of our customers.

- Quality Assurance: Every product undergoes stringent quality checks to ensure compliance with international standards.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers complete customization services for ground molybdenum plates, including size, thickness, surface finish, and material properties. Our team works closely with clients to deliver products tailored to their exact specifications.

|

|

|

|

|

|

|

|

|

FAQ

-

What is the lead time for orders? Lead times vary depending on the order size and specifications, but typically range from 4-6 weeks.

-

Can I request custom sizes? Yes, we offer complete customization to meet specific dimensional requirements.

-

Do you provide samples? Yes, we can provide samples upon request for evaluation purposes.

-

What industries can use ground molybdenum plates? Ground molybdenum plates are widely used in electronics, aerospace, defense, energy, medical, and nuclear industries.

-

What packaging options do you offer? We offer wooden, carton, foam-filled, waterproof, and custom packaging solutions to ensure safe transportation.

Contact Us

Are you ready to experience the quality and reliability of Shaanxi Peakrise Metal Co., Ltd.’s ground molybdenum plates? We invite global buyers to get in touch with us at info@peakrisemetal.com. Let us help you find the perfect molybdenum solution for your application.

YOU MAY LIKE

-

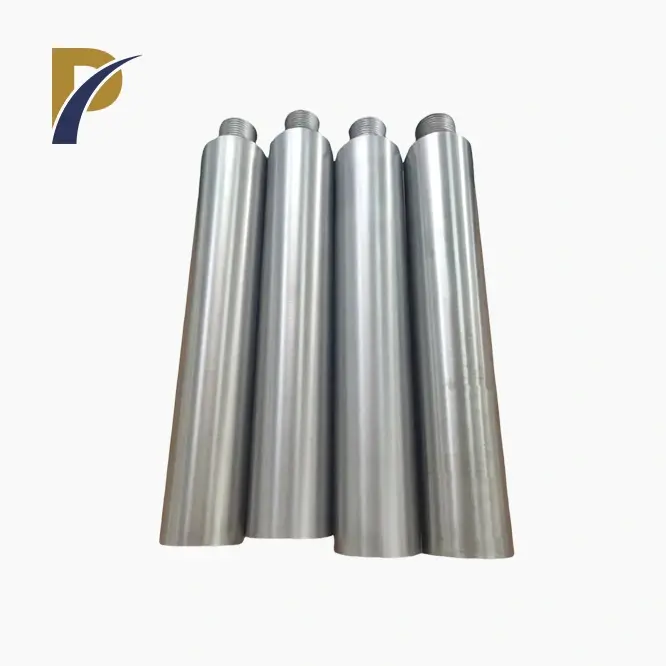

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode -

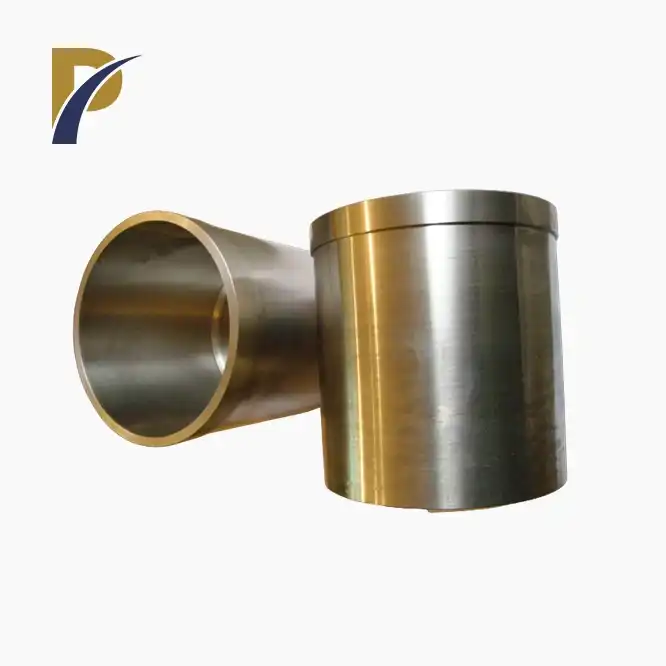

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREsapphire crucible molybdenum

VIEW MOREsapphire crucible molybdenum -

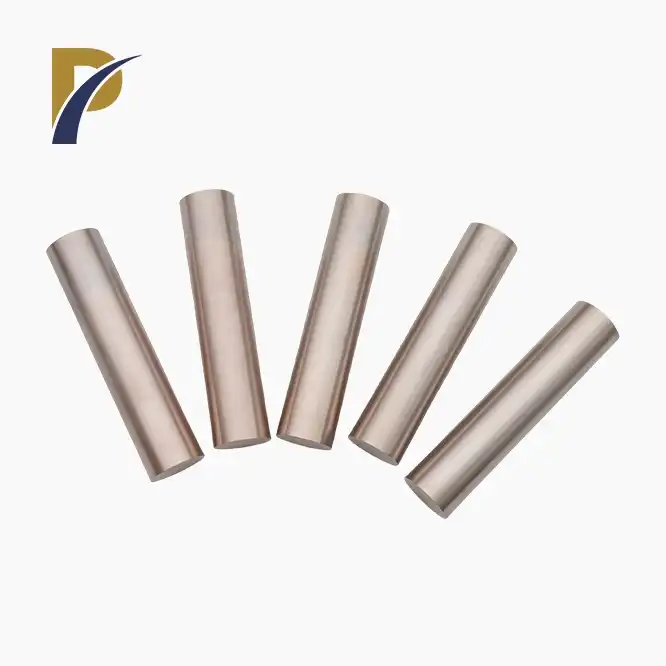

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREmolybdenum in x ray tube

VIEW MOREmolybdenum in x ray tube -

VIEW MOREtungsten electrodes

VIEW MOREtungsten electrodes -

VIEW MOREtungsten copper alloy rod

VIEW MOREtungsten copper alloy rod -

VIEW MOREhigh temperature furnace tungsten crucible

VIEW MOREhigh temperature furnace tungsten crucible

_1734924254976.webp)