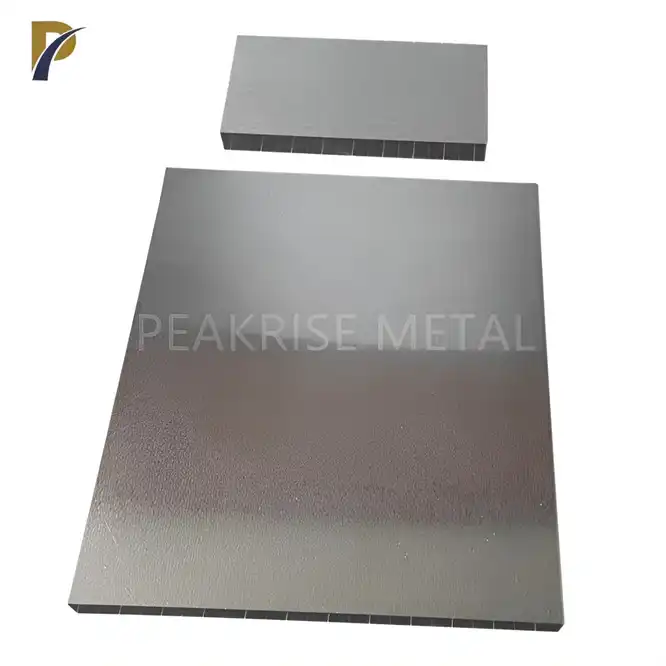

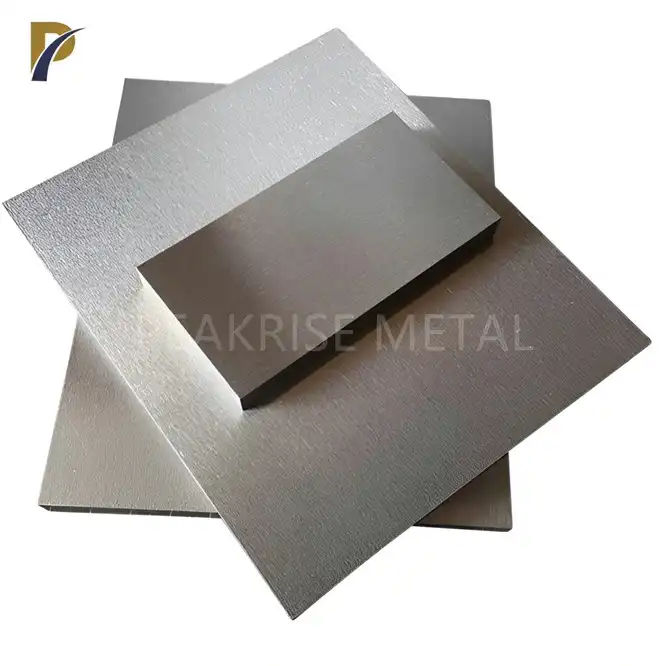

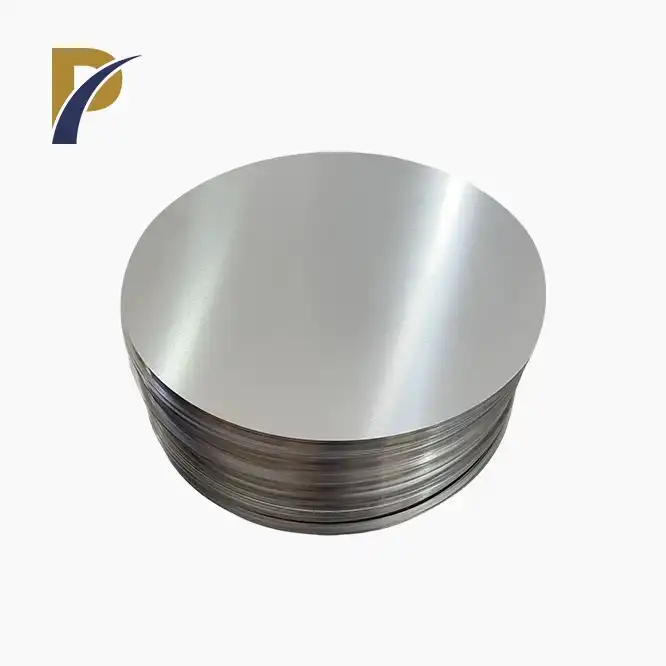

ASTM B386 molybdenum plate

W Content: 50% (wt%)

Mo Content: 50% (wt%)

Shape: Rod,Plate,Crucible,Custom Parts

Advantage: High Strength

Surface: Bright

Work Temperature:>1800℃

PRODUCT DESCRIPTION

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is a leading supplier of high-quality non-ferrous metal products, including the fASTM B386 molybdenum plate . This product is an essential component in specialized industries such as aerospace, defense, and high-end manufacturing due to its excellent physical and mechanical properties. Molybdenum is well-known for its durability, high melting point, and resistance to corrosion, making it a vital material in creating reliable and durable components like the plate belt of fending. Shaanxi Peakrise Metal Co., Ltd. has gained a strong reputation as a trusted supplier of these molybdenum products worldwide. Our expertise in the production and processing of molybdenum ensures that our clients receive materials that meet the highest international standards. With years of experience in the non-ferrous metals industry, we are capable of providing both standard and customized molybdenum products to meet diverse application needs.

Our ASTM B386 molybdenum plate is designed for customers seeking materials that can withstand extreme environments while offering superior strength and longevity. Whether you need it for high-temperature industrial processes or for use in corrosive environments, this product ensures top-notch performance.

Product Parameters Table

| Description | Grade | Density g/cm3 |

Size (mm) | Application | |

| Large Size | High temperature molybdenum plate, molybdenum alloy sheet | Mo-La TZM |

>9.8 | (20-40) x (90-240) x (200-600) | Good high temperature performance and machinability |

| High purity molybdenum sheet | Mo | 10.2 | Suitable for rolling pure molybdenum sheet | ||

| Small Size | High purity molybdenum sheet | Mo | 16 x 16 x 160 | Suitable for rolling molybdenum foil and molybdenum disc | |

| Parameter | Value | Unit |

|---|---|---|

| Electrical Resistivity | 0.05 | µΩ·m |

| Thermal Conductivity | 138 | W/m·K |

| Modulus of Elasticity | 329 | GPa |

| Specific Heat Capacity | 0.25 | J/g·K |

| Hardness (Vickers) | 180 - 240 | HV |

|

|

|

Physical and Mechanical Properties

Molybdenum is well-regarded for its outstanding thermal and mechanical properties, including:

- High Melting Point: With a melting point of 2623°C, molybdenum plates are ideal for high-temperature applications.

- Superior Strength: The tensile strength of 690 MPa ensures robust structural integrity under heavy loads.

- Corrosion Resistance: Molybdenum’s resistance to most forms of corrosion makes it suitable for harsh environments.

- Low Coefficient of Thermal Expansion: This ensures minimal deformation under temperature changes, providing long-lasting stability.

| Product Name | Molybdenum sheet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tensile strength | 610 Mpa | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Elongation | ≥10% | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity | ≥99.95%,≥99.97%, | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Size | TK 0.1~80mm*W 10~700mm*L 30~3000mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Use temperature | 1800°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Highest temperature | 2200°C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quantitative analysis | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | Ni | Mg | Fe | Pb | Al | Bi | Si | Cd | Ca | P | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.003 | 0.002 | 0.005 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.0001 | 0.002 | 0.001 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| Element | C | O | N | Sb | Sn | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Concentration(%) | 0.01 | 0.003 | 0.003 | 0.0005 | 0.0001 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Purity(Metallic Base) Mo≥99.95% | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

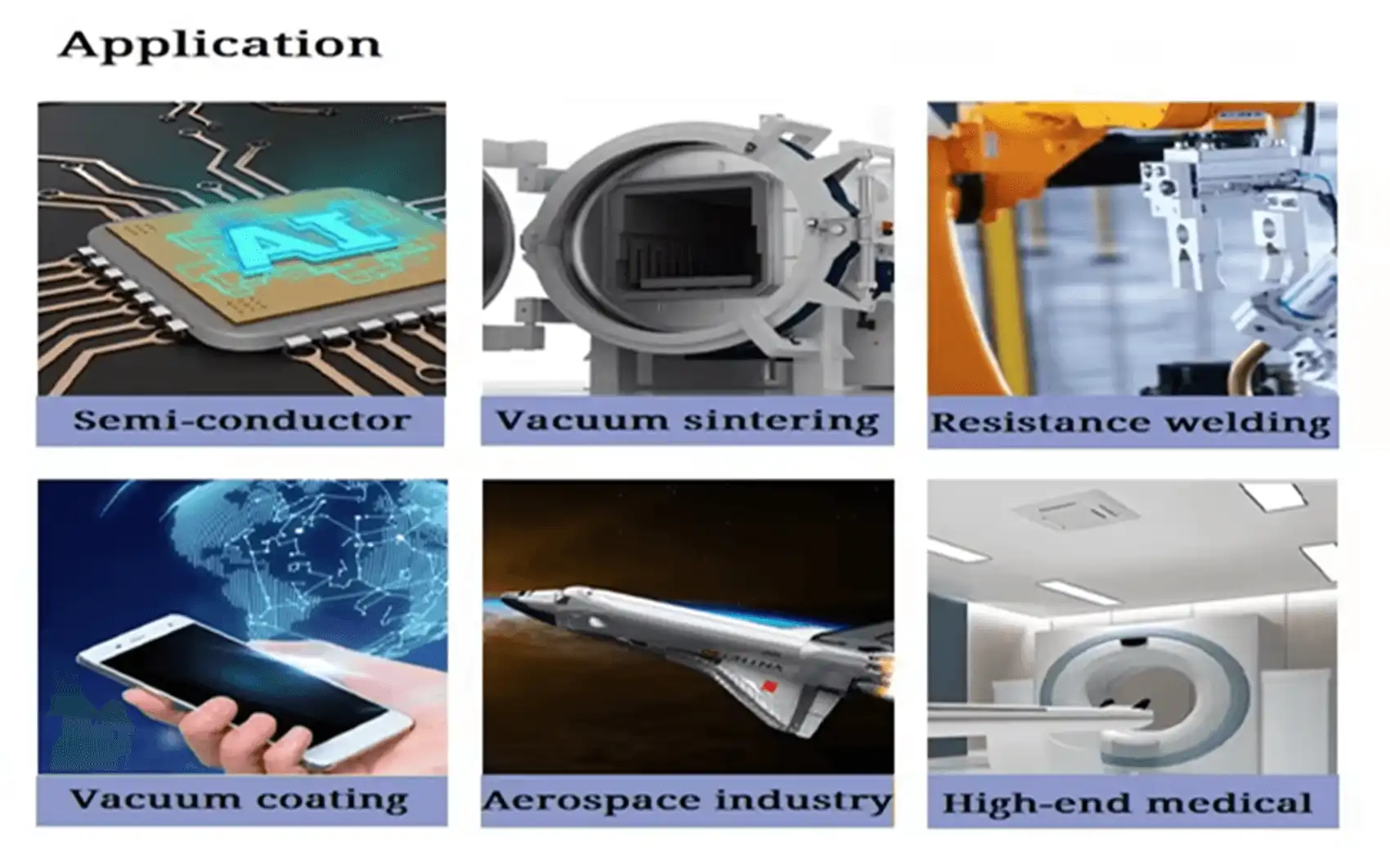

Product Applications

- Aerospace Industry: The molybdenum plate belt is utilized in components that require excellent strength and stability at high altitudes and extreme temperatures.

- Nuclear Power: With its resistance to radiation and high temperatures, molybdenum is often used in reactor components.

- Defense Sector: The durability and heat resistance of the plate belt make it suitable for use in military equipment such as armored vehicles and missile parts.

- Chemical Processing: Its corrosion resistance makes it an ideal material for equipment used in chemical plants.

- Electronics: Used in the production of advanced electronics, where precision and reliability are crucial.

Product Process and Production Flow

-

Molybdenum powder---isostatic pressing---stamping rolling---induction sintering (guaranteed by hydrogen)---molybdenum sheet compact---hot rolling---annealing---basic acid washing---cold connection Rolling mill cold rolling---wide molybdenum sheet.

Of course, this is only one of the methods for the preparation of molybdenum sheet. There are other methods such as rolling, forging and casting.

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with the latest production and testing machinery, including vacuum furnaces, CNC machines, and plasma cutting systems. Our experienced staff and engineers ensure that every product meets stringent international standards.

|

|

|

|

Logistics and Packaging

- Packaging Options:

- Wooden crates for enhanced protection during shipping.

- Foam-filled cartons to prevent damage.

- Waterproof and moisture-proof materials for international shipping.

- Custom packaging based on client specifications.

- Logistics:

- Sea freight for large orders.

- Air freight for expedited deliveries.

- Land transport within regions.

- Courier services for small orders or samples.

|

|

|

|

|

|

|

|

Why Choose Us?

- Expertise: With over a decade of experience in non-ferrous metal production, we guarantee high-quality molybdenum products.

- Global Reach: Our products are exported to over 20 countries worldwide, including the USA, South Korea, and Germany.

- Custom Solutions: We offer flexible OEM/ODM services to meet the specific needs of each client.

- State-of-the-art Facilities: Our factory is equipped with cutting-edge production machinery.

- Commitment to Quality: We strictly adhere to international quality standards, ensuring consistency and reliability in every batch.

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. supports a full range of OEM/ODM services. Whether you need custom sizes, finishes, or packaging, our team is ready to work with you to create tailored solutions that meet your project requirements.

FAQ

-

What is the purity of the molybdenum used in the plate belt? Our molybdenum has a purity of 99.95%, ensuring high performance in critical applications.

-

Can you provide custom dimensions? Yes, we offer fully customizable sizes to meet specific project needs.

-

What is the typical lead time for bulk orders? Standard lead times range from 4 to 6 weeks, depending on the order size.

-

Do you offer sample testing? Yes, we can provide samples for testing before placing a bulk order.

-

How do you ensure the quality of your products? Each product undergoes strict quality control, including mechanical and chemical testing, to meet international standards.

Contact Us

Interested in our ASTM B386 molybdenum plate ? Contact us today at info@peakrisemetal.com to learn more about our products, request a quote, or discuss custom solutions for your business. We look forward to partnering with you to deliver high-quality molybdenum products tailored to your needs.

YOU MAY LIKE

-

VIEW MOREmolybdenum electrodes glass melting

VIEW MOREmolybdenum electrodes glass melting -

VIEW MOREmolybdenum lanthanum furnace boats

VIEW MOREmolybdenum lanthanum furnace boats -

VIEW MOREmolybdenum crucible uhv evaporator

VIEW MOREmolybdenum crucible uhv evaporator -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MOREtungsten and molybdenum alloy rod

VIEW MOREtungsten and molybdenum alloy rod -

VIEW MORE0.1mm molybdenum sheet /plate

VIEW MORE0.1mm molybdenum sheet /plate -

VIEW MOREmolybdenum alloy strip/foil

VIEW MOREmolybdenum alloy strip/foil -

VIEW MOREmolybdenum wires

VIEW MOREmolybdenum wires