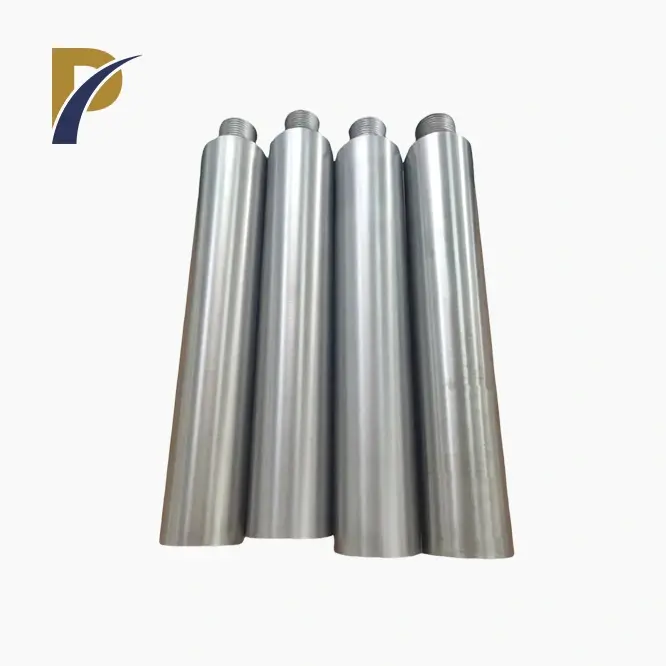

tungsten and molybdenum electrodes

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

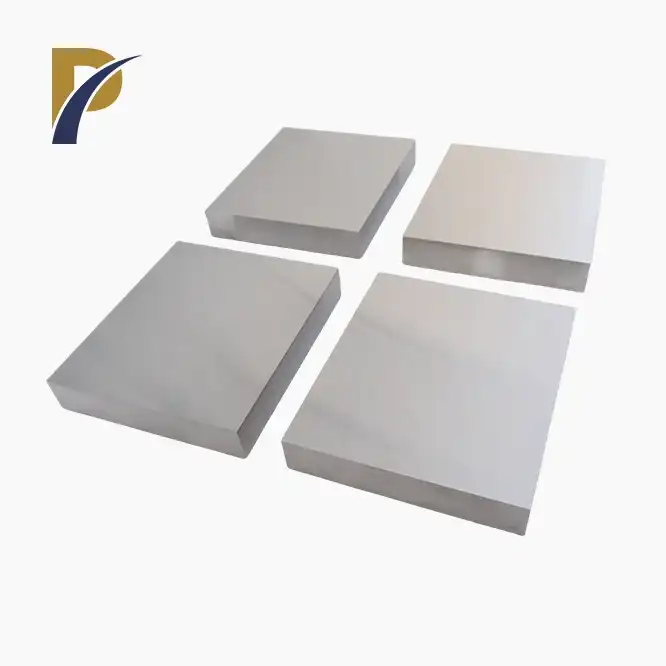

PRODUCT DESCRIPTION

Tungsten and Molybdenum Electrodes Product Introduction

Tungsten and molybdenum electrodes are essential in high-temperature and high-intensity industrial applications. As one of the most reliable suppliers in the field, Shaanxi Peakrise Metal Co., Ltd. provides high-quality tungsten and molybdenum electrodes for various industries. Our electrodes are renowned for their excellent thermal and electrical conductivity, high melting points, and resistance to corrosion, making them ideal for applications in industries such as electronics, glass melting, and aerospace.

At Shaanxi Peakrise Metal, we take pride in producing tungsten and molybdenum electrodes that meet strict international standards. Our products are widely used in the manufacture of semiconductors, lighting components, and furnace components. With nearly a decade of experience in non-ferrous metal production, including tungsten, molybdenum, tantalum, and other alloys, we have earned the trust of clients worldwide. Our products have been exported to Taiwan, Ukraine, South Korea, the United States, Australia, Germany, and beyond, building long-lasting relationships with satisfied customers.

Product Parameters Table

| Property | Tungsten Electrode | Molybdenum Electrode |

|---|---|---|

| Purity (%) | ≥ 99.95 | ≥ 99.95 |

| Melting Point (°C) | 3,422 | 2,623 |

| Density (g/cm³) | 19.3 | 10.28 |

| Electrical Resistivity (Ω·m) | 5.5 x 10⁻⁸ | 5.34 x 10⁻⁸ |

| Thermal Conductivity (W/m·K) | 173 | 138 |

|

|

|

Physical and Mechanical Properties

Tungsten and molybdenum both possess unique characteristics that make them ideal for high-performance applications:

-

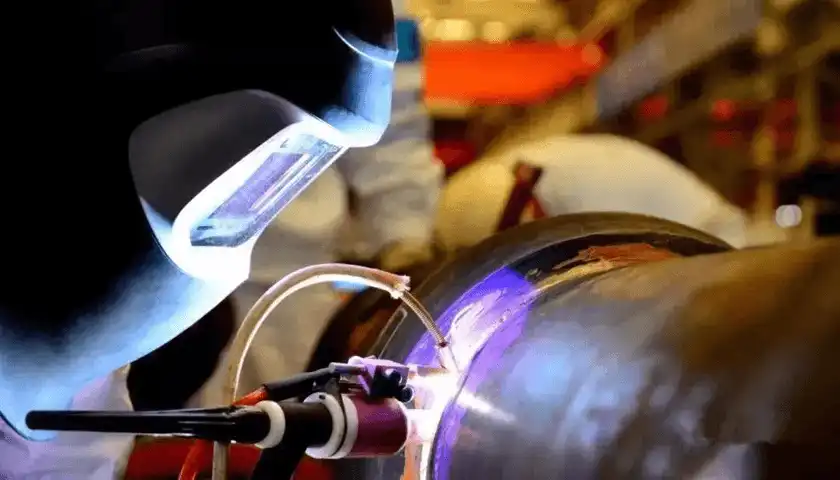

Tungsten: Known for its extremely high melting point (3,422°C), tungsten provides unmatched durability in high-temperature environments. It offers excellent corrosion resistance and mechanical strength, making it suitable for electrode applications in welding and metal-cutting processes.

-

Molybdenum: With a slightly lower melting point (2,623°C), molybdenum still excels in high-heat environments. Its superior thermal conductivity and low thermal expansion properties make it highly effective in electronic and glass-melting industries.

Product Functions

-

High Melting Point: Tungsten and molybdenum's ability to maintain structural integrity at extreme temperatures ensures performance in demanding applications such as arc welding, glass melting, and furnace operations.

-

Thermal Conductivity: These electrodes efficiently transfer heat, reducing energy consumption and ensuring consistency in industrial processes.

-

Corrosion Resistance: Both materials resist oxidation and chemical reactions, extending their lifespan even in harsh environments.

-

Electrical Conductivity: With excellent electrical conductivity, tungsten and molybdenum are ideal for electrodes in electric discharge machining (EDM) and semiconductor manufacturing.

Product Applications

-

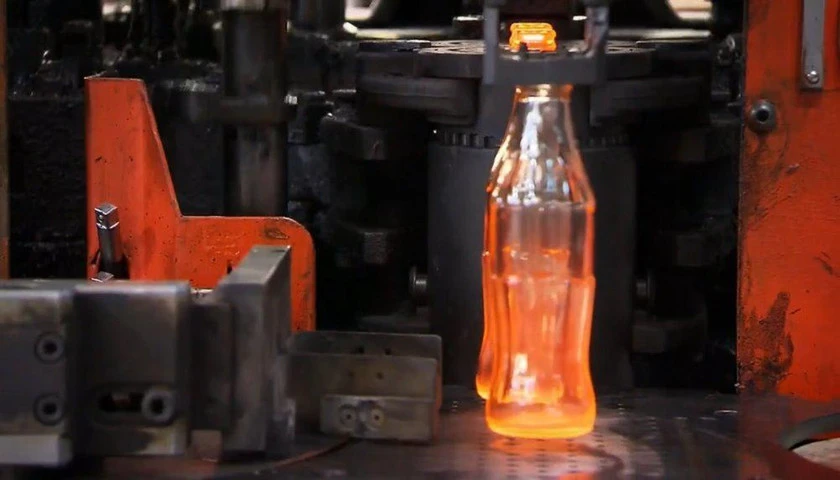

Glass Melting Industry: Tungsten and molybdenum electrodes are commonly used in glass furnaces due to their ability to withstand high temperatures and corrosive environments, providing longevity and reliability in glass production.

-

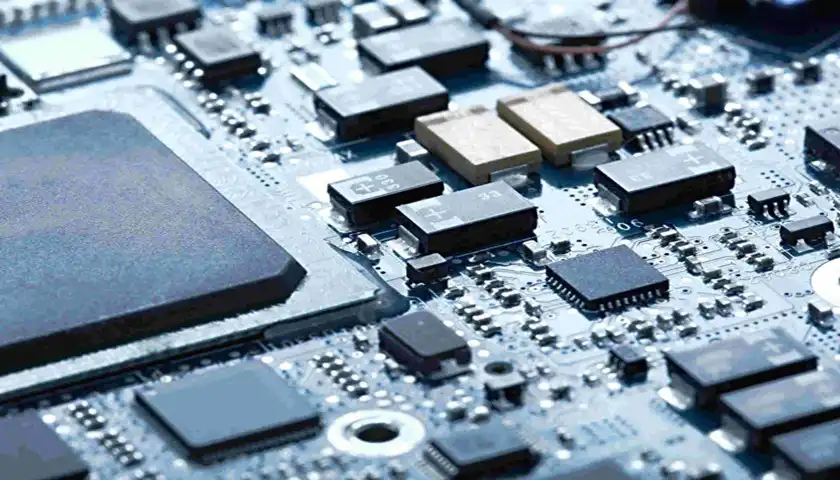

Electronics and Semiconductors: Both metals are crucial in semiconductor manufacturing, where their high electrical conductivity and heat resistance are essential for producing components like transistors and integrated circuits.

-

Lighting Industry: Tungsten is particularly important in lighting applications, such as the production of incandescent light filaments, due to its ability to emit light when heated.

-

Aerospace and Defense: Tungsten and molybdenum alloys are used in aerospace applications for their high strength-to-weight ratios, resistance to thermal expansion, and ability to perform under extreme temperatures and pressures.

|

|

|

Product Process and Production Flow

The production process of tungsten and molybdenum electrodes at Shaanxi Peakrise Metal Co., Ltd. follows a stringent manufacturing protocol to ensure high quality and consistency:

-

Raw Material Selection: We use the highest purity tungsten and molybdenum powders, ensuring that the final product meets international standards.

-

Powder Metallurgy: The metals undergo a powder metallurgy process, where they are compacted and sintered to form solid electrodes.

-

Machining and Finishing: The sintered materials are then machined to the precise dimensions required by the application, ensuring tight tolerances and superior surface finishes.

-

Quality Control: Every batch of electrodes undergoes rigorous testing to ensure adherence to customer specifications and international standards.

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. boasts state-of-the-art production facilities equipped with advanced technologies, including intermediate frequency sintering furnaces, vacuum arc melting furnaces, and CNC machining centers. Our experienced technicians and engineers work tirelessly to maintain the highest quality standards in every product we manufacture. Our factory is certified under ISO9001, demonstrating our commitment to quality and customer satisfaction.

|

|

|

|

|

|

|

|

|

|

Logistics and Packaging

- Wooden Crates: Protects against physical damage during transit.

- Foam-filled Cartons: Ensures secure packaging for sensitive components.

- Waterproof Packaging: Prevents moisture-related damage.

- Custom Packaging: Tailored to meet specific customer requirements.

Logistics options include:

- Sea Freight: Cost-effective for bulk orders.

- Air Freight: Faster delivery for urgent shipments.

- Land Transport: Reliable and timely delivery for domestic orders.

- Courier Services: Suitable for small, urgent orders.

|

|

|

|

|

|

|

|

Why Choose Us?

- Industry Experience: Over a decade of expertise in the production and export of non-ferrous metals, including tungsten and molybdenum.

- Advanced Technology: Our cutting-edge machinery ensures precision and quality in every electrode we produce.

- Global Reach: Our products are trusted by clients across the world, with exports to over ten countries.

- Customized Solutions: We offer OEM and ODM services to meet the specific needs of our customers.

OEM Services

Shaanxi Peakrise Metal Co., Ltd. supports custom manufacturing services for tungsten and molybdenum electrodes, allowing customers to specify dimensions, material properties, and surface treatments.

|

|

FAQ

-

What is the purity of your tungsten and molybdenum electrodes?

Our electrodes have a minimum purity of 99.95%, ensuring high performance in industrial applications. -

Can you provide custom dimensions for the electrodes?

Yes, we offer full customization to meet specific project requirements. -

What industries are your electrodes suitable for?

Our tungsten and molybdenum electrodes are used in industries such as electronics, glass melting, aerospace, and welding. -

Do you offer samples for testing?

Yes, we provide samples to qualified customers for evaluation before placing bulk orders. -

How are your products shipped?

We offer multiple shipping options, including sea freight, air freight, and courier services, depending on your location and urgency.

Contact Us

We welcome inquiries from global purchasers. Contact us at info@peakrisemetal.com for more information or to discuss your project requirements. Let Shaanxi Peakrise Metal Co., Ltd. be your trusted partner in tungsten and molybdenum electrode solutions.

YOU MAY LIKE

-

VIEW MORE50 diameter molybdenum elecrtode

VIEW MORE50 diameter molybdenum elecrtode -

VIEW MOREtzm molybdenum alloy rod

VIEW MOREtzm molybdenum alloy rod -

VIEW MORErolling molybdenum plate

VIEW MORErolling molybdenum plate -

VIEW MOREmolybdenum alloy strip/foil

VIEW MOREmolybdenum alloy strip/foil -

VIEW MOREmolybdenum wires

VIEW MOREmolybdenum wires -

VIEW MOREtungsten electrode for aluminium

VIEW MOREtungsten electrode for aluminium -

VIEW MOREhigh temperature furnace tungsten crucible

VIEW MOREhigh temperature furnace tungsten crucible -

VIEW MOREtungsten crucible for induction furnace

VIEW MOREtungsten crucible for induction furnace