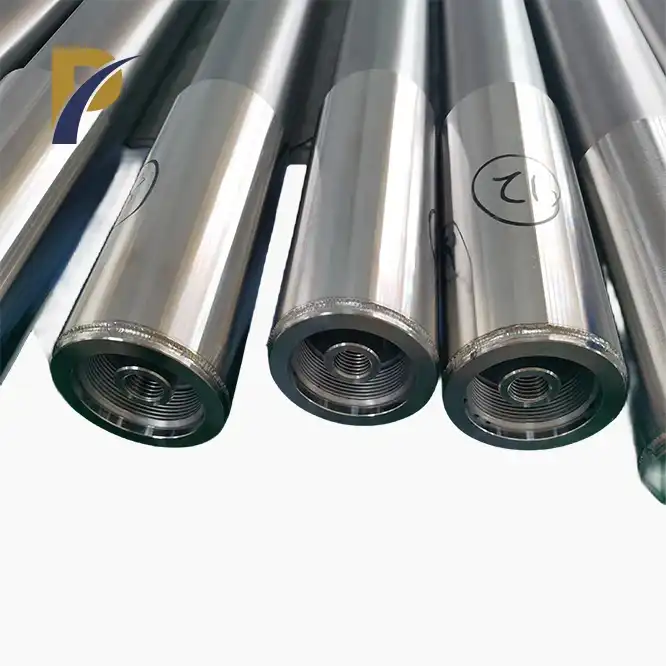

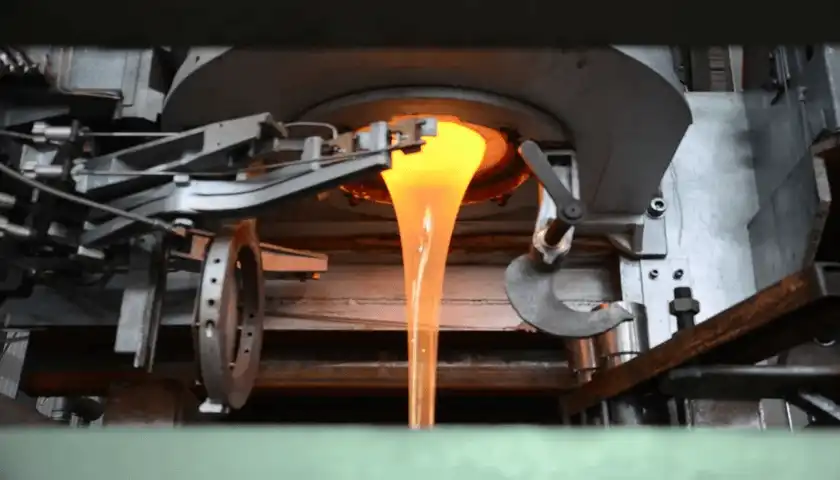

molybdenum electrodes for Opal Glass Furnace

Purity: 99.97%

Diameter: 4~120mm

Length: 200~2000mm

Surface: Polished

Standard: ASTM B387

Tensile Strength:≥900MPa

Tensile Strength:≥900MPa

Elongation: ≥15%

Application:Daily glass, optical glass, thermal insulation materials, glass fiber, rare earth industry and other fields

PRODUCT DESCRIPTION

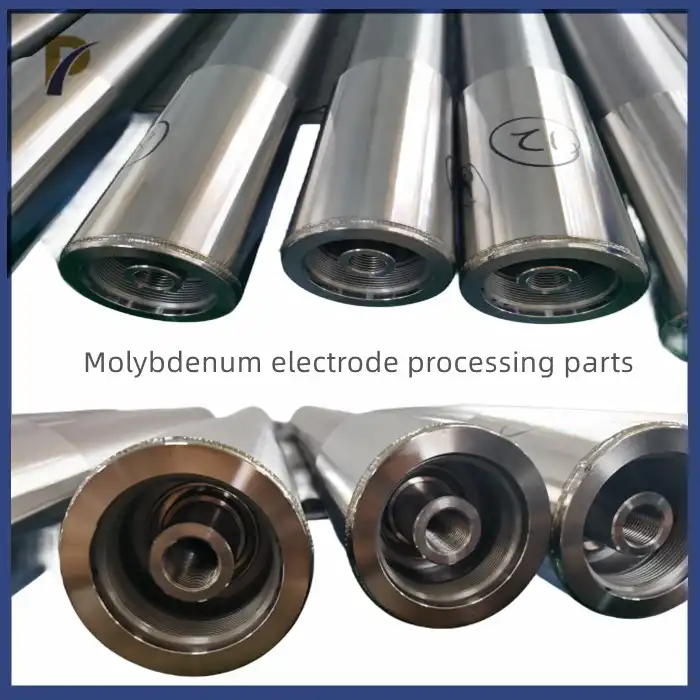

Molybdenum Electrodes for Tap Disintegrator - Product Introduction

Molybdenum electrode for glass melting furnace is an electrode used in the glass industry and is widely used in the melting process of glass. Molybdenum electrode for glass melting furnace is usually made of high-purity molybdenum material, and its surface treatment adopts special technical process. The size and shape of molybdenum electrodes can be customized according to different furnace types and glass production process requirements. Molybdenum electrodes are mainly used in the melting process of electroslag melting glass and sodium glass, and have the advantages of high temperature corrosion resistance and long life.

As a leading manufacturer, Shaanxi Peakrise Metal Co., Ltd. not only provides premium molybdenum electrodes but also delivers comprehensive support, ensuring that each customer receives products designed to fit their specific industrial needs. Our commitment to quality, innovation, and customer satisfaction has allowed us to establish long-term relationships with clients across the globe. Whether you are looking for molybdenum electrodes for disintegrating metal parts or specialized applications, Peakrise Metal is your go-to supplier. We offer customizable solutions to match the diverse requirements of various industries, making us a reliable partner in the global marketplace.

|

|

|

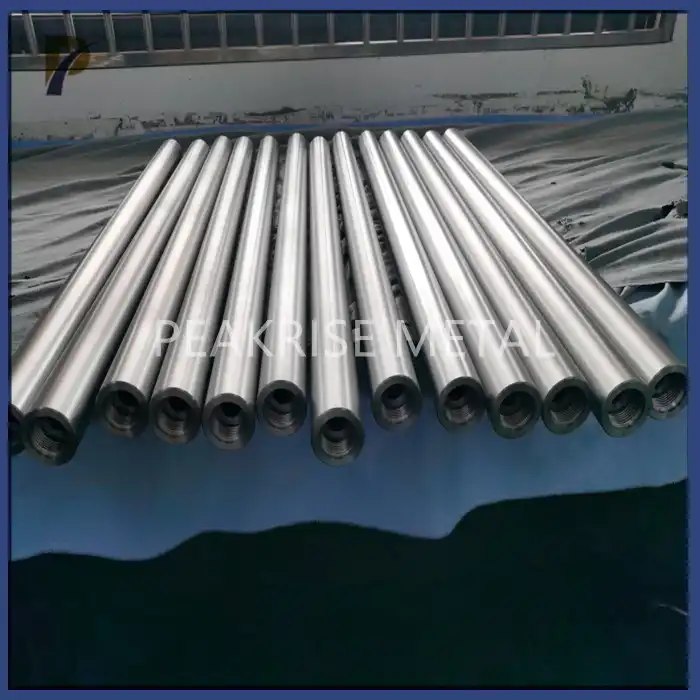

Product Parameters

| Diameter | 10~100mm |

| Length | 150~3000mm |

| Purity | 99.97% |

| Density | 10.2g/cm3 |

| Straightness |

Forging rod ≤1% Sintered rod ≤2% |

| Elongation | ≥10% |

| Melting Point | 2620℃ |

| Diameter and Tolerance (mm) | ||

|

Forged or Sintered molybdenum rod |

<10 | ±0.1 |

| 10~30 | ±0.1 | |

| 30~60 | ±0.1 | |

| 60~100 | ±0.2 | |

| 100~200 | ±0.2 | |

| >200 | custom as per customer request | |

Physical and Mechanical Properties

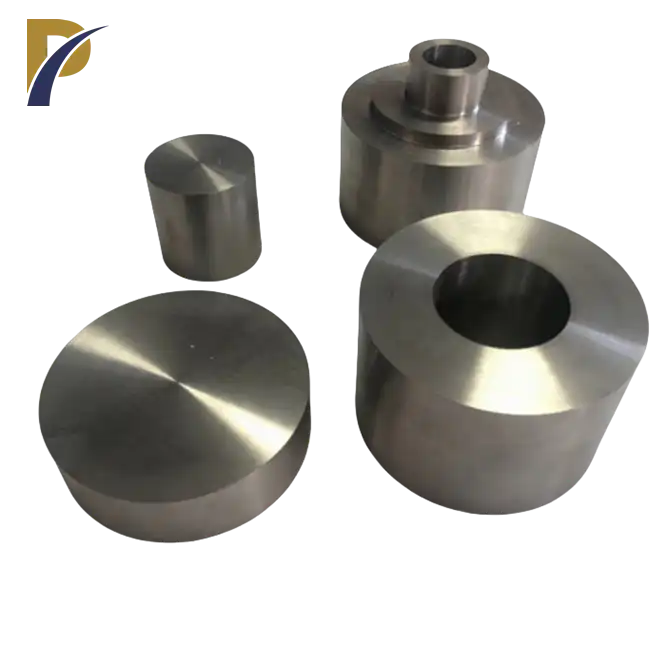

Molybdenum electrodes exhibit outstanding mechanical and thermal properties, making them ideal for use glass melting furnace. Their high melting point of 2623°C allows them to function effectively in extreme heat without compromising their structural integrity. Additionally, molybdenum has a high tensile strength, enabling it to resist deformation under significant stress. Molybdenum's superior electrical conductivity ensures that the electrodes transmit current efficiently, making them highly efficient in their primary function of disintegrating metallic materials in industrial processes.

Product Functions

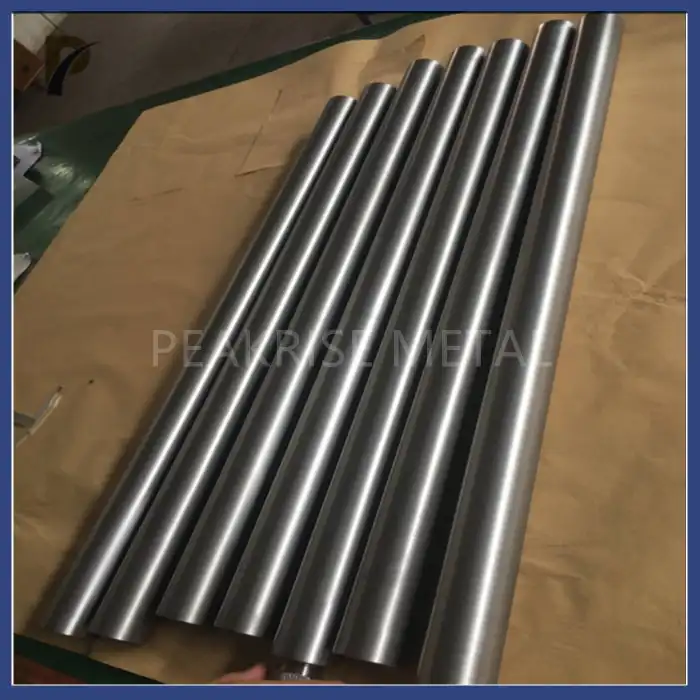

- High-Temperature Resistance: Molybdenum electrodes can operate at extremely high temperatures without losing their mechanical properties, making them ideal for heavy industrial applications.

- Superior Electrical Conductivity: These electrodes conduct electricity with minimal energy loss, improving the overall efficiency of tap disintegration processes.

- Wear Resistance: Molybdenum's resistance to wear and corrosion ensures that the electrodes have a long service life, even in harsh conditions.

- Dimensional Stability: Molybdenum electrodes maintain their shape and functionality despite repeated exposure to intense heat and mechanical stress.

- Cost-Effectiveness: Due to their durability and extended service life, molybdenum electrodes offer a cost-effective solution for industries requiring frequent disintegration of metal parts.

High Melting Point

Excellent Conductivity

Corrosion Resistance

High Thermal Conductivity

Product Applications

- Tap Disintegration: Molybdenum electrodes are widely used in tap disintegrators for breaking down metal parts in industries such as manufacturing, automotive, and aerospace. Their high conductivity and temperature resistance make them ideal for this purpose.

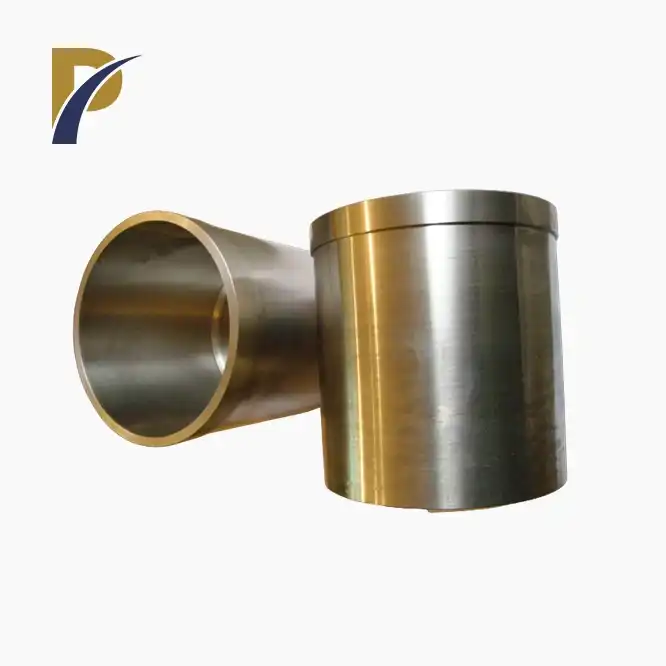

- Glass Melting Electrodes: Their ability to withstand high temperatures also makes molybdenum electrodes suitable for use in glass furnaces, where they help maintain the high heat required for melting glass.

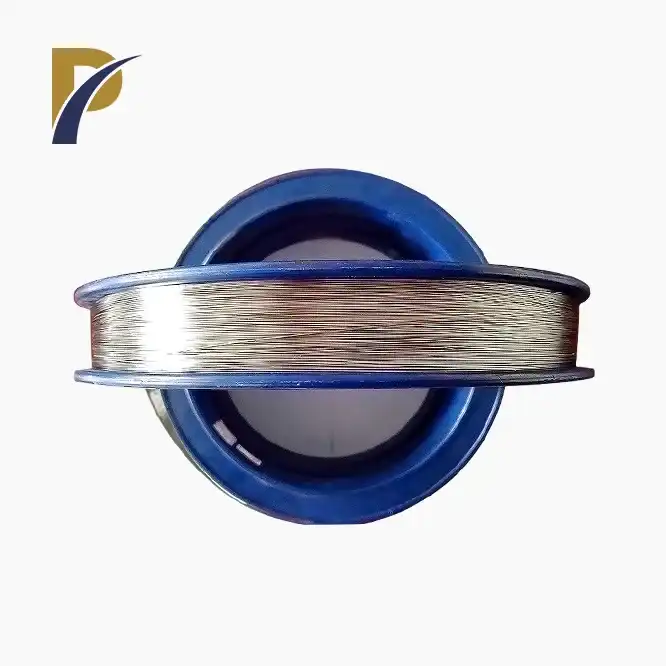

- Semiconductor Manufacturing: Molybdenum’s purity and electrical properties are beneficial in the production of semiconductors, where precise electrical performance is critical.

- Metalworking and Foundry Applications: Molybdenum electrodes are used in various metalworking processes where high heat and durability are needed, such as in the production of steel and non-ferrous alloys.

- Electric Arc Furnaces: The electrodes can be used in electric arc furnaces for melting and refining metals.

|

|

OEM/ODM Services

Shaanxi Peakrise Metal Co., Ltd. offers flexible OEM/ODM services to meet the unique specifications of our clients. Whether you require a specific electrode size, shape, or purity level, we can tailor our products to match your exact needs. Our experienced engineers work closely with customers to ensure that all products are manufactured to the highest standards of quality and precision. We are committed to delivering personalized solutions that enhance the performance and longevity of your equipment.

|

|

|

|

|

|

|

|

|

|

Our Quality Inspection

|

|

|

|

|

|

|

|

|

|

Why Choose Us?

- Industry Expertise: With over a decade of experience in the production of molybdenum, tungsten, tantalum, and other non-ferrous metals, Shaanxi Peakrise Metal is a trusted name in the industry.

- Comprehensive Product Range: We offer over 100 types of non-ferrous metal products, including molybdenum-copper alloys and tungsten-molybdenum alloys, ensuring that we can meet diverse customer needs.

- Advanced Manufacturing Capabilities: Our state-of-the-art facilities are equipped with intermediate frequency sintering furnaces, vacuum arc melting furnaces, and other advanced machinery to ensure the highest quality products.

- Global Reach: Our products are exported to countries such as the United States, Germany, Australia, and South Korea, demonstrating our ability to meet international standards and customer expectations.

- Customer-Centric Approach: We prioritize the satisfaction of our clients by providing high-quality products, personalized services, and timely delivery.

FAQ

-

What is the lifespan of molybdenum electrodes in tap disintegration?

- The lifespan of molybdenum electrodes depends on usage conditions but typically exceeds that of other materials due to their high wear resistance and temperature stability.

-

Can you customize electrode sizes for specific applications?

- Yes, we offer customizable solutions for various industrial needs, including different sizes, shapes, and material compositions.

-

What packaging options are available for shipping?

- We provide custom packaging options, including wooden crates, foam-filled cartons, and waterproof wrapping to ensure the safe delivery of products.

-

Do you offer OEM services?

- Yes, we specialize in providing OEM services tailored to the unique specifications of our clients.

-

How quickly can you fulfill international orders?

- We maintain a robust stock inventory and can fulfill international orders promptly, with flexible shipping options available.

Logistics and Packaging

-

Packaging Options:

- Wooden Crates

- Foam-Filled Cartons

- Waterproof and Moisture-Proof Wrapping

- Custom Packaging Solutions

- International Standard Packaging

-

Logistics:

- Sea Freight

- Air Freight

- Land Transport

- Multimodal Transport

- Express Courier Services

|

|

|

|

|

|

|

|

Contact Us

For more information about our molybdenum electrodes for tap disintegrators or to request a quote, please contact us at info@peakrisemetal.com. We look forward to partnering with global buyers to deliver high-quality non-ferrous metal products that meet the demands of your industry.