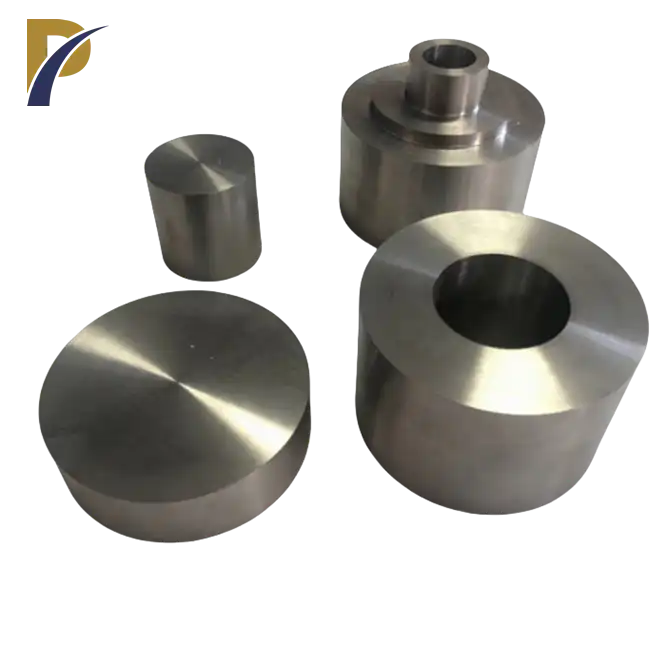

high quality molybdenum crucible

Purity: 99.95%

Density: 10.2g/cm3

Shape: Crucible

Diameter: Max.450mm

Height: Max.800mm

Finish: Ra<1.6

Craft: Sintering,Machined

Application: Metallurgical industry, rare earth industry, monocrystalline silicon, solar energy, artificial crystal and mechanical processing industries.

PRODUCT DESCRIPTION

Product Introduction

Shaanxi Peakrise Metal Co., Ltd. is a renowned supplier of high-quality molybdenum crucibles, designed for the most demanding industrial applications. Our molybdenum crucibles are crafted with precision and expertise, meeting the needs of sectors such as metallurgy, electronics, and chemical processing, where high temperatures and durability are critical. Made from the purest molybdenum, these crucibles withstand temperatures up to 2600°C, offering exceptional resistance to thermal shock and corrosion. With over a decade of experience in non-ferrous metals, we provide tailored solutions to customers worldwide, ensuring the highest quality products to improve operational efficiency. Our molybdenum crucibles are recognized for their purity, strength, and excellent performance in high-temperature environments, making them an ideal choice for industries requiring reliable thermal containment solutions.

Shaanxi Peakrise Metal Co., Ltd. has become a trusted name in non-ferrous metal production. We specialize in molybdenum crucibles and various alloys, offering global clients superior materials, custom solutions, and unmatched quality standards. Our products are used extensively in Taiwan, Ukraine, South Korea, the United States, Australia, and Germany, where they have earned a strong reputation for performance and reliability.

Product Parameters

| Parameter | Specification |

|---|---|

| Purity | ≥ 99.95% |

| Density | ≥ 10.2 g/cm³ |

| Melting Point | 2620°C |

| Maximum Operating Temperature | 2600°C |

| Dimensions (Customizable) | Ø 50mm to Ø 500mm |

| Wall Thickness | 2mm to 10mm |

| Tolerance | ±0.01mm |

| Physical Properties | Value |

|---|---|

| Tensile Strength | 640 MPa |

| Hardness (HV) | 240-290 HV |

| Thermal Expansion Coefficient | 4.8 x 10⁻⁶ /K |

| Electrical Conductivity | 30% IACS |

| Thermal Conductivity | 138 W/m·K |

| Specific Heat Capacity | 0.25 J/g·K |

|

|

|

Physical and Mechanical Properties

Our molybdenum crucibles feature superior mechanical properties, making them ideal for high-temperature applications. They are known for their high melting point, excellent thermal conductivity, and low thermal expansion, providing enhanced performance in extreme conditions. With a density of 10.2 g/cm³ and a thermal conductivity of 138 W/m·K, these crucibles efficiently manage heat, reducing thermal stress and prolonging lifespan in industrial processes.

Product Functions

-

Heat Resistance: Molybdenum crucibles can withstand extreme temperatures, making them essential for high-temperature furnaces, vacuum environments, and other industrial processes requiring thermal containment.

-

Corrosion Resistance: These crucibles offer excellent resistance to chemical corrosion, maintaining integrity when exposed to aggressive environments such as molten metals or high-temperature gases.

-

Mechanical Strength: With high tensile strength and hardness, molybdenum crucibles provide long-lasting durability, even in demanding applications.

-

Thermal Conductivity: Their superior thermal conductivity ensures uniform heat distribution, improving process efficiency and reducing energy consumption.

|

|

|

Product Applications

Molybdenum crucibles play a crucial role in industries that operate under extreme conditions, and their applications include:

-

Metallurgical Industry: Used for melting and casting metals like platinum, palladium, and special alloys due to their ability to withstand very high temperatures.

-

Electronics Industry: Essential in semiconductor manufacturing, molybdenum crucibles are used in vapor deposition processes, which require precise thermal control.

-

Aerospace Industry: The high melting point and structural integrity of molybdenum crucibles make them ideal for growing synthetic sapphire crystals used in advanced aerospace technologies.

-

Chemical Processing: With exceptional resistance to corrosive environments, they are widely used for chemical reactions involving corrosive agents at elevated temperatures.

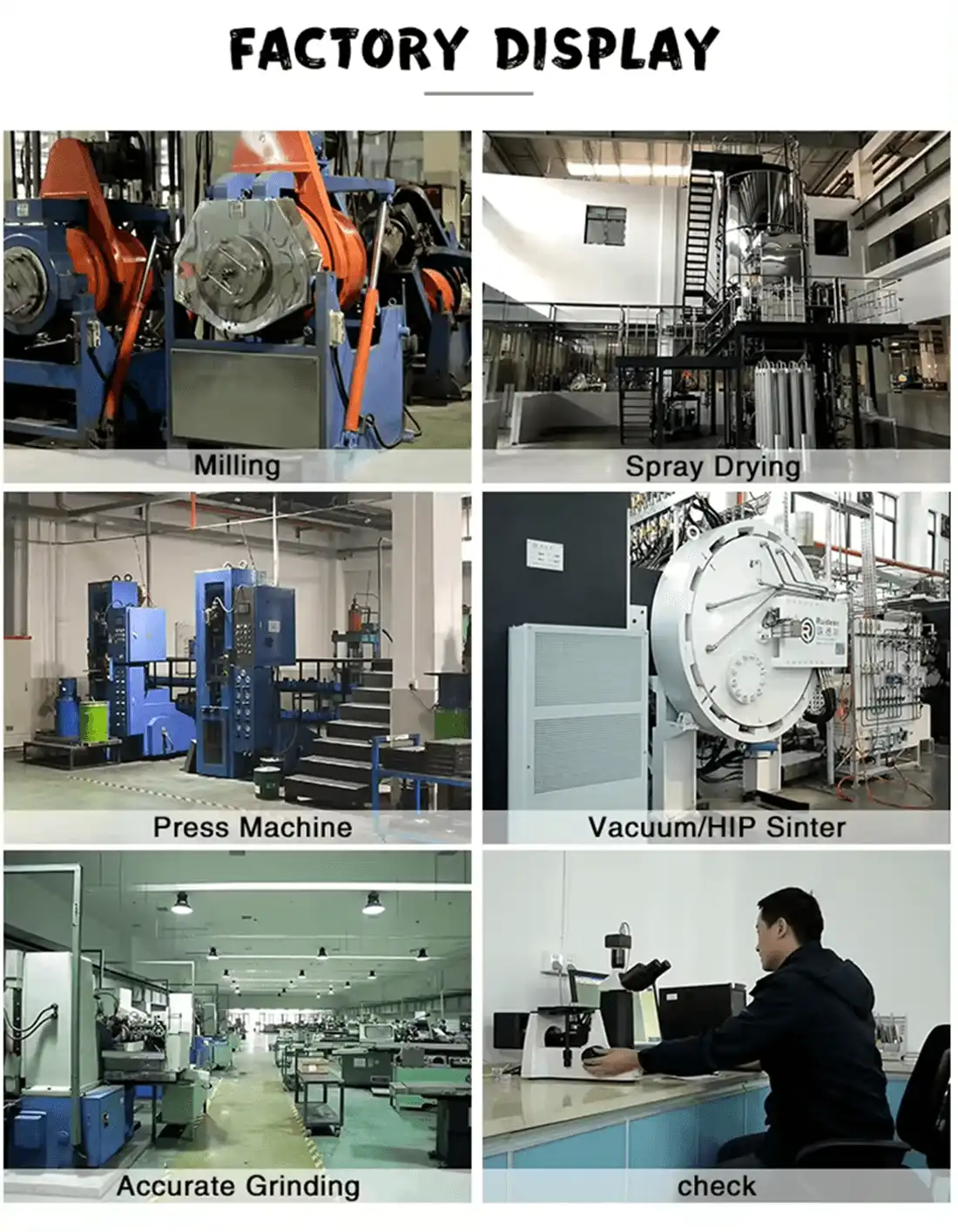

Product Process and Production Flow

Our molybdenum crucibles undergo rigorous manufacturing processes, ensuring precision and quality:

-

Raw Material Selection: We source the highest purity molybdenum to ensure performance and durability in end products.

-

Forming and Sintering: The raw molybdenum is pressed into the desired shape and sintered in a vacuum or hydrogen environment to achieve maximum density and strength.

-

Machining and Finishing: Crucibles are machined to tight tolerances to meet exact specifications, followed by surface finishing for optimal performance.

-

Quality Control: Each crucible undergoes comprehensive quality checks, including dimensional accuracy, purity verification, and structural integrity tests, ensuring they meet international standards.

|

|

|

|

Our Factory

Shaanxi Peakrise Metal Co., Ltd. operates a state-of-the-art manufacturing facility equipped with vacuum arc melting furnaces, intermediate frequency sintering furnaces, plasma welding equipment, and advanced machining tools. With over ten years of experience, we are fully capable of meeting global demand for high-quality non-ferrous metal products. Our commitment to excellence has earned us partnerships with clients in more than 20 countries, consistently delivering on quality and service.

Logistics and Packaging

- Wooden Crate Packaging: Designed for maximum protection during long-distance transportation.

- Foam-Filled Packaging: Provides cushioning to protect crucibles from impact.

- Moisture-Proof Packaging: Ensures the product remains dry during transport.

- Customized Packaging: Tailored to meet specific shipping requirements, following international standards.

Logistics Options:

- Sea Freight: Cost-effective for bulk orders, ideal for long-distance shipping.

- Air Freight: Fast and efficient for urgent deliveries.

- Multimodal Transport: Combining various transport modes for optimized logistics.

- Courier Services: For smaller, urgent shipments requiring swift delivery.

|

|

|

|

|

|

|

|

Why Choose Us?

- Experienced Manufacturer: Over 10 years in non-ferrous metal production, with extensive experience in molybdenum crucible manufacturing.

- Advanced Production Equipment: Utilizing state-of-the-art machinery for high precision and quality.

- Global Reach: Established relationships with international clients across various industries.

- Customization Options: We offer tailor-made solutions to meet specific customer requirements.

- Commitment to Quality: ISO 9001 certified, ensuring consistent quality and adherence to industry standards.

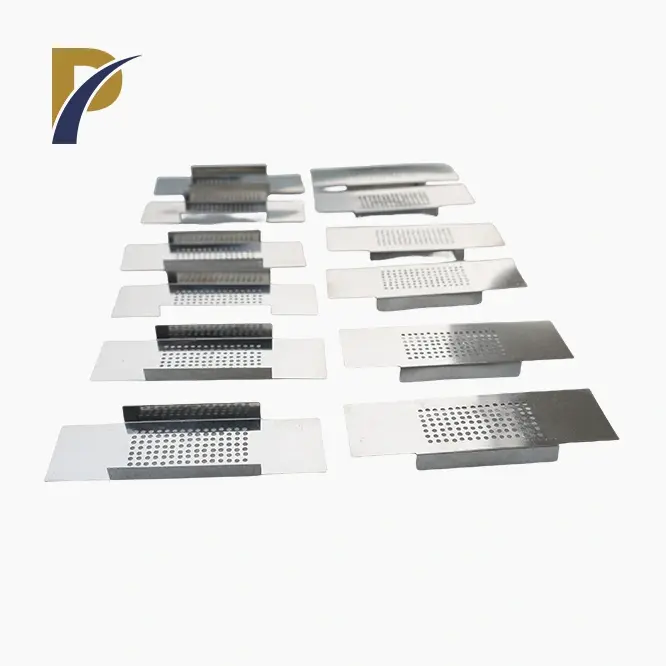

OEM Services

Shaanxi Peakrise Metal Co., Ltd. offers comprehensive OEM/ODM services, allowing customers to customize molybdenum crucibles to their specifications. From size and shape to material composition, we work closely with our clients to deliver tailored solutions that meet their exact needs.

|

|

|

|

|

|

|

|

|

FAQ

-

What is the maximum temperature molybdenum crucibles can withstand? Molybdenum crucibles can withstand temperatures up to 2600°C, making them suitable for high-temperature processes.

-

Can you customize molybdenum crucibles based on specific requirements? Yes, we offer full customization services to meet your specific needs in terms of size, shape, and purity.

-

What is the typical lead time for an order? Depending on order quantity and customization, our typical lead time is 2-4 weeks.

-

What quality certifications does your company have? We are ISO 9001 certified, ensuring our products meet the highest international quality standards.

-

How do you ensure the product quality during shipment? We use moisture-proof, foam-filled, and wooden crate packaging to ensure the product is well-protected during transport.

Contact Us (CTA)

For more information on our high-quality molybdenum crucibles or to request a quote, please contact us at info@peakrisemetal.com. We look forward to partnering with you and providing tailored solutions to meet your industrial needs.